A kind of midsole material and forming method thereof of ultra-light and high-rebound etpu composite shock-absorbing shoes

A high-resilience and shock-absorbing shoe technology, applied in the field of shoe manufacturing, can solve the problems of increasing foaming pressure and foaming temperature, reducing material density, and reducing the hardness of foamed materials, so as to increase the interface bond strength. , The effect of improving processing performance and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

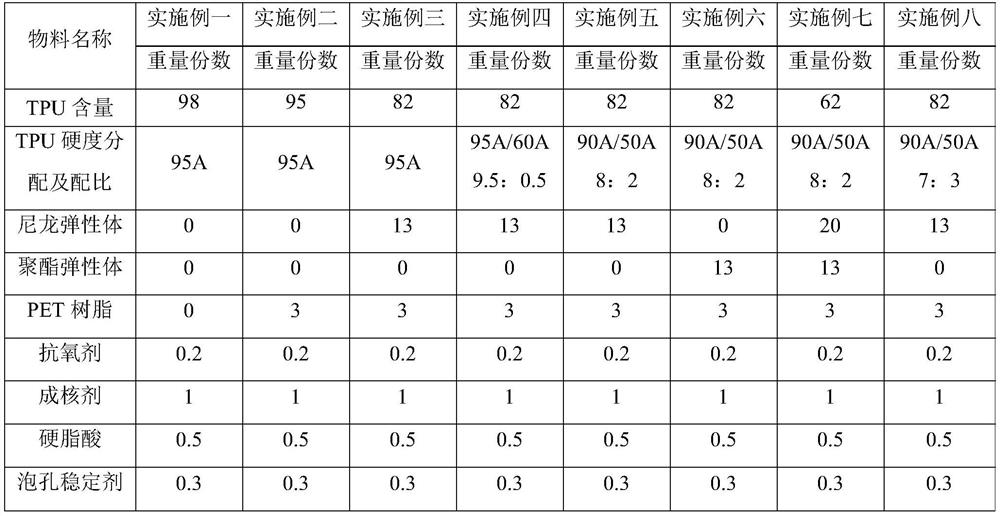

Embodiment 1

[0039] In an embodiment of the present invention, the TPU composite material includes the following components in parts by mass:

[0040] TPU with a Shore hardness of 95A: 98 parts

[0041] Antioxidant: 0.2 parts

[0042] Nucleating agent: 1 part

[0043] Stearic acid: 0.5 parts

[0044] Cell stabilizer: 0.3 parts

[0045] Wherein, the antioxidant is AT-10; the nucleating agent is white carbon black; the cell stabilizer is acrylic compound.

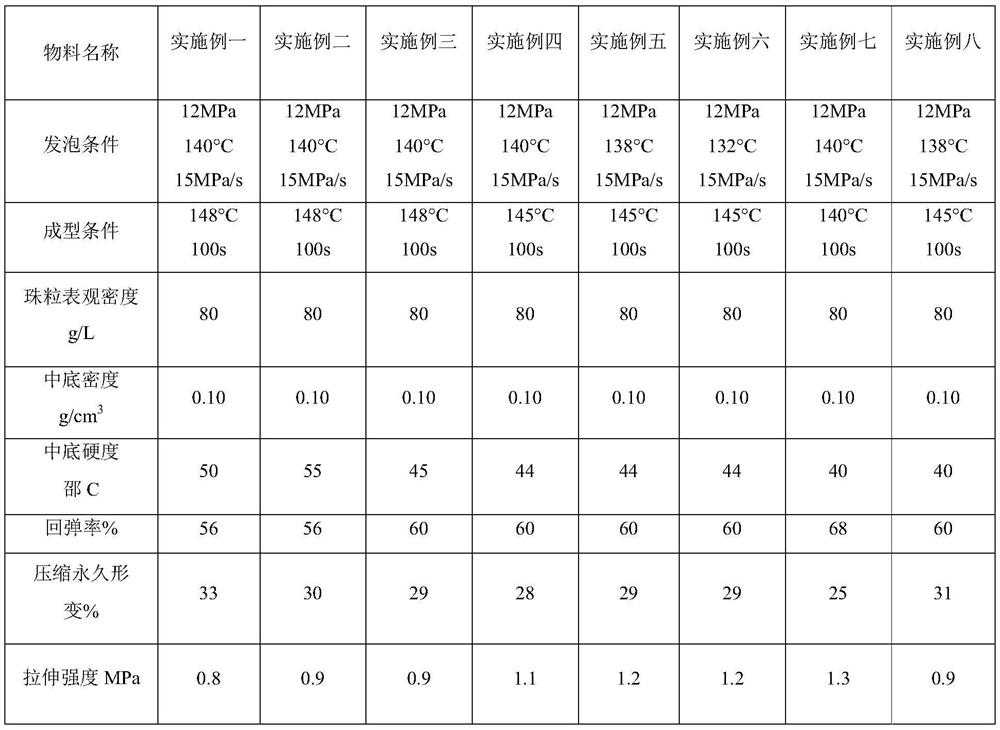

[0046] After drying and mixing the above components, put them into the barrel of a twin-screw extruder, extrude after melting and kneading, and cool and cut under water to obtain TPU composite particles; , impregnated in a carbon dioxide atmosphere at a temperature of 140 ° C until the solubility is balanced, and the pressure is quickly released at a speed of 15 MPa / s to rapidly expand the TPU composite particles. After drying, sieving, and aging, the apparent density is 80 g / s. ETPU composite particles of L; inject the ETPU composit...

Embodiment 2

[0048] In an embodiment of the present invention, the TPU composite material includes the following components in parts by mass:

[0049] TPU with a Shore hardness of 95A: 95 parts

[0050] Polyester resin: 3 parts

[0051] Antioxidant: 0.2 parts

[0052] Nucleating agent: 1 part

[0053] Stearic acid: 0.5 parts

[0054] Cell stabilizer: 0.3 parts

[0055] Wherein, the antioxidant is AT-10; the nucleating agent is white carbon black; the cell stabilizer is acrylic compound.

[0056] After drying and mixing the above components, put them into the barrel of a twin-screw extruder, extrude after melting and kneading, and cool and cut under water to obtain TPU composite particles; , impregnated in a carbon dioxide atmosphere at a temperature of 140 ° C until the solubility is balanced, and the pressure is quickly released at a speed of 15 MPa / s to rapidly expand the TPU composite particles. After drying, sieving, and aging, the apparent density is 80 g / s. ETPU composite parti...

Embodiment 3

[0058] In an embodiment of the present invention, the TPU composite material includes the following components in parts by mass:

[0059] TPU with a Shore hardness of 95A: 82 parts

[0060] Nylon elastomer: 13 parts

[0061] Polyester resin: 3 parts

[0062] Antioxidant: 0.2 parts

[0063] Nucleating agent: 1 part

[0064] Stearic acid: 0.5 parts

[0065] Cell stabilizer: 0.3 parts

[0066] Wherein, the antioxidant is AT-10; the nucleating agent is white carbon black; the cell stabilizer is acrylic compound.

[0067]After drying and mixing the above components, put them into the barrel of a twin-screw extruder, extrude after melting and kneading, and cool and cut under water to obtain TPU composite particles; , impregnated in a carbon dioxide atmosphere at a temperature of 140 ° C until the solubility is balanced, and the pressure is quickly released at a speed of 15 MPa / s to rapidly expand the TPU composite particles. After drying, sieving, and aging, the apparent densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com