Cinerous glass ceramic and preparation method and application thereof

A technology of glass-ceramics and glass-ceramic frit, which is applied in the field of blue-gray glass-ceramics and its preparation, can solve the problems of high energy consumption, high porosity, and single color, and achieve excellent physical and chemical properties, soft color, and improved The effect of L value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

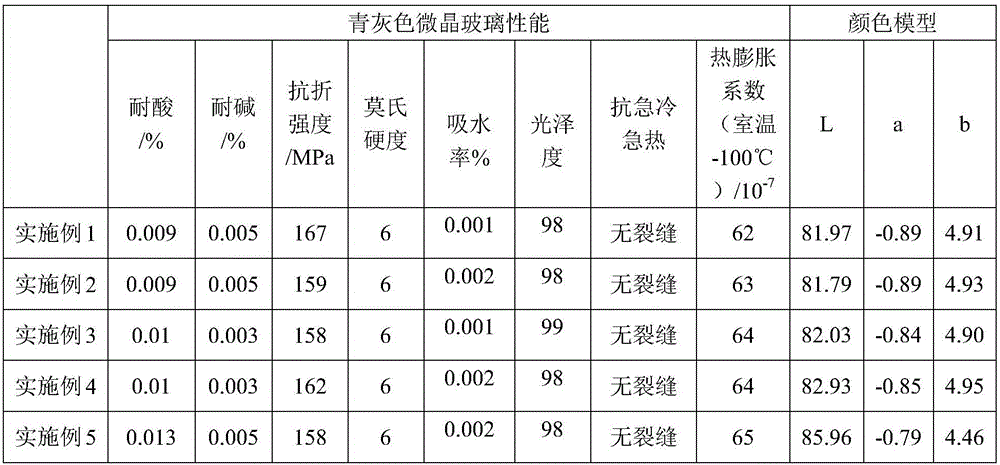

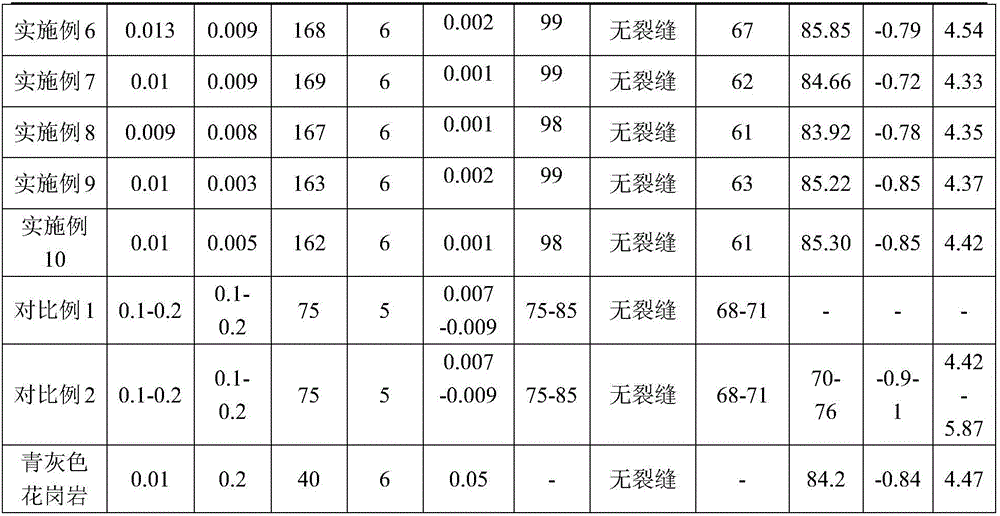

Examples

Embodiment 1

[0032] A kind of blue-gray glass-ceramics, by weight percentage, including the following raw materials: SiO 2 37.2%; Al 2 o 3 28%; CaO 7.8%; MgO 6.5%; Na 2 O 12%; TiO 2 6%; ZrO 2 0.5%; CeO 2 2%.

[0033] The preparation of blue-gray glass-ceramics comprises the following steps:

[0034] A. Prepare raw materials: weigh the raw materials according to the above weight percentage, mix them evenly, and obtain the batch materials;

[0035] B. Preparation of basic glass: melting the batch material obtained in step A at 1535°C, cooling the melted liquid to 770-860°C and forming it to obtain the basic glass;

[0036] C. Preparation of blue-gray glass-ceramics: After the basic glass obtained in step B is nucleated at 710-740°C for 15-25min, crystallized at 875-885°C for 15-25min, annealed at 810-850°C, cut and polished, A blue-gray glass-ceramic was obtained.

[0037] The application of a kind of blue-gray glass-ceramics in imitation natural blue-gray granite glass-ceramic...

Embodiment 2

[0042] A kind of blue-gray glass-ceramics, by weight percentage, including the following raw materials: SiO 2 34.1%; Al 2 o 3 30%; CaO 9.6%; MgO 8%; Na 2 O 6%; K 2 O 4%; ZnO 0.8%; TiO 2 5.2%; CeO 2 2.3%.

[0043] The preparation of blue-gray glass-ceramics comprises the following steps:

[0044] A. Prepare raw materials: weigh the raw materials according to the above weight percentage, mix them evenly, and obtain the batch materials;

[0045] B. Preparation of basic glass: Melt the batch obtained in step A at 1543°C, cool the melted liquid to 780-850°C, and form it to obtain the basic glass;

[0046] C. Preparation of blue-gray glass-ceramics: After the basic glass obtained in step B is nucleated at 720-730°C for 18-20min, crystallized at 880-887°C for 18-20min, annealed at 820-840°C, cut and polished, A blue-gray glass-ceramic was obtained.

[0047] The application of a kind of blue-gray glass-ceramics in imitation natural blue-gray granite glass-ceramics compris...

Embodiment 3

[0052] A kind of blue-gray glass-ceramics, by weight percentage, including the following raw materials: SiO 2 43.2%; Al 2 o 3 29%; CaO 7.2%; MgO 6%; Na 2 O 4%; K 2 O 2%; TiO 2 7%; CeO 2 1.5%; Fe 2 o 3 0.1%.

[0053] The preparation of blue-gray glass-ceramics comprises the following steps:

[0054] A. Prepare raw materials: weigh the raw materials according to the above weight percentage, mix them evenly, and obtain the batch materials;

[0055] B. Preparation of basic glass: Melt the batch obtained in step A at 1570°C, cool the melted liquid to 780-840°C, and form it to obtain the basic glass;

[0056] C. Preparation of blue-gray glass-ceramics: After the basic glass obtained in step B is nucleated at 720-750°C for 10-20min, crystallized at 873-875°C for 10-20min, annealed at 815-835°C, cut and polished, A blue-gray glass-ceramic was obtained.

[0057] The application of a kind of blue-gray glass-ceramics in imitation natural blue-gray granite glass-ceramics c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com