Air floating type guide wheel transmission device for liquid crystal panel

A liquid crystal panel and conveying device technology, applied in packaging, conveyors, electrical components, etc., can solve problems such as product yield decline, and achieve the effects of avoiding pollution, reducing particle generation, and improving yield and productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

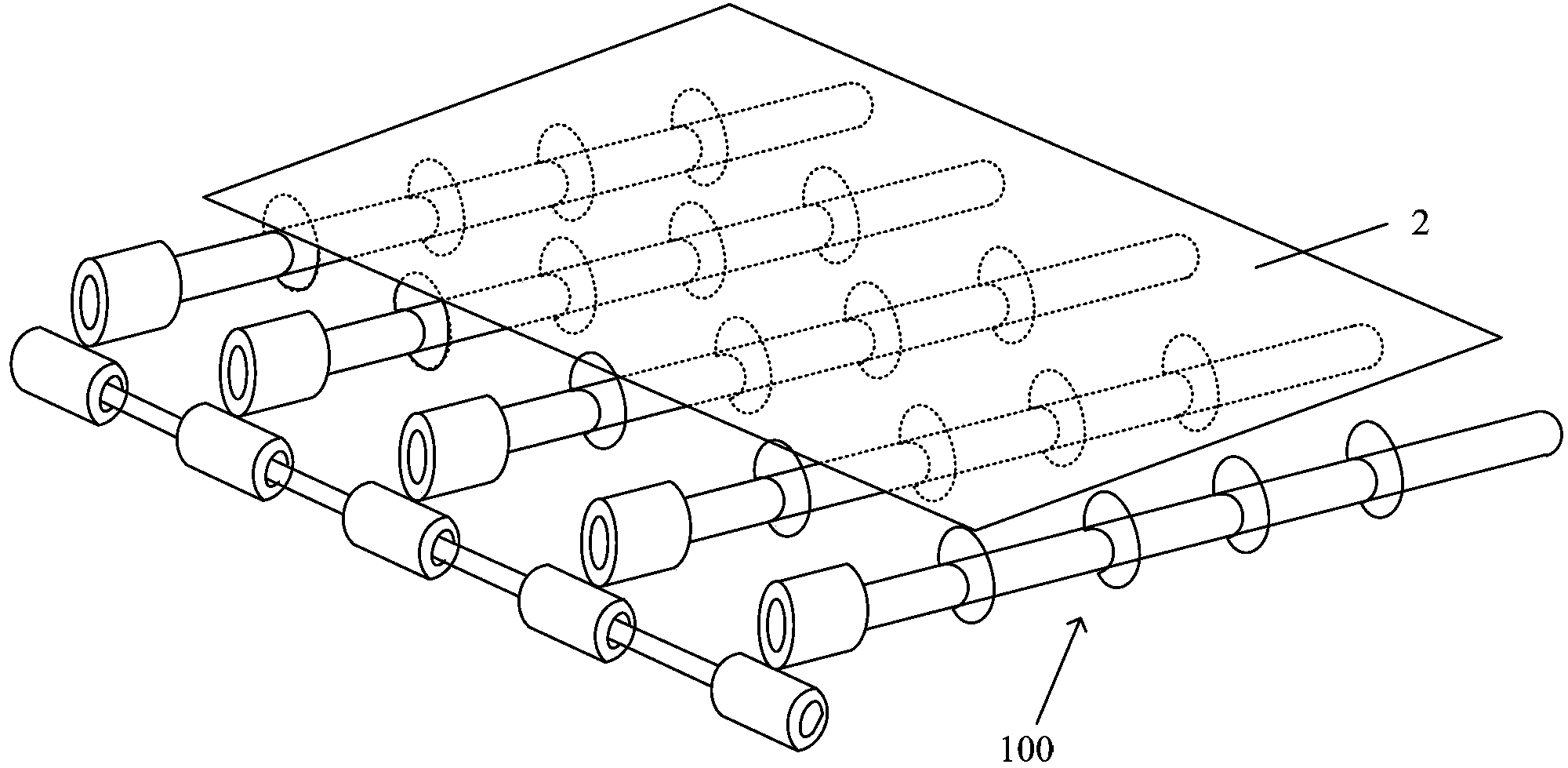

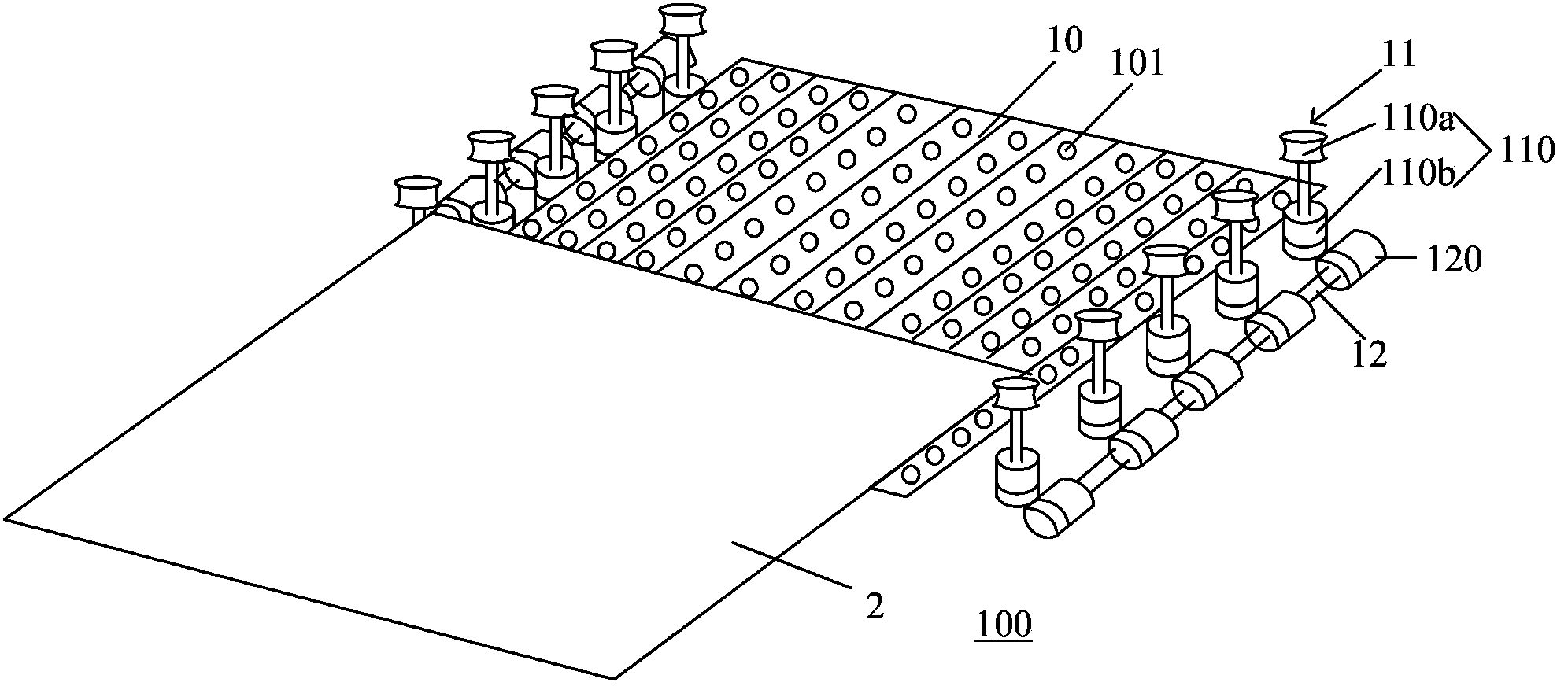

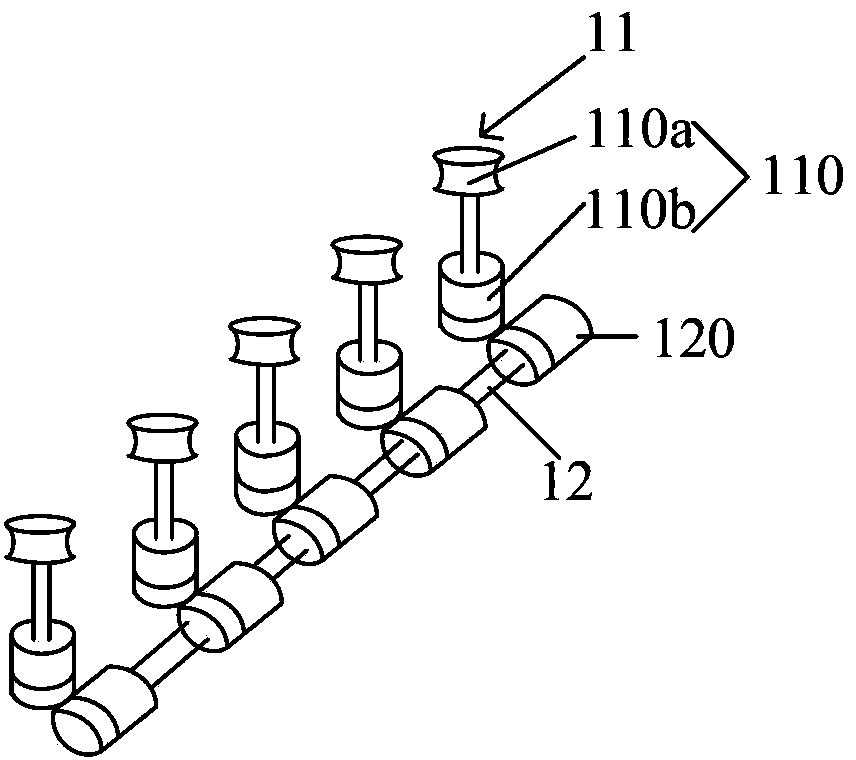

[0015] refer to figure 2 As shown, the present invention provides an air-floating guide wheel transmission device 100 for a liquid crystal panel, which uses pneumatic transmission to guide and transport the liquid crystal panel 2, and includes: an air-floating support platform 10, two guide wheel sets 11 and a magnetic wheel driving device 12, wherein the air-floating support platform 10 is provided with several air holes 101, and the two guide wheel sets 11 are arranged on both sides of the air-floating support platform 10 in parallel, the The magnetic wheel drive device 12 is linked with the guide wheel set 11, and drives the guide wheel set 11 to rotate through the rolling of the magnetic wheel drive device 12, blows air from the air hole 101 of the air-floating support platform 10, and passes the guide wheel The group 11 guides and limits the two sides of the liquid crystal panel 2 to transport the liquid crystal panel 2 along the rotation direction of the guide wheel gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com