Degradable lightweight polyolefin composite for injection molding and preparation method of composite

A composite material and polyolefin technology, which is applied in the field of degradable lightweight polyolefin composite materials for injection molding, can solve the problems of high energy consumption and low output, and achieve the effects of reduced surface area, low wear and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] For the specific preparation method, see the operation steps in (2) below.

[0078] Preparation method of polyolefin / modified hybrid fiber filler injection molding composite material:

[0079] (1) Screening and alkalization of rice husk plant fiber powder. In Example 1-7, the impurity-free rice husk was crushed through a 40-60 mesh sieve to obtain a plant fiber powder, and the plant fiber powder was soaked in a 2% mass fraction NaOH solution at 80° C. for 4 hours, and then separated by centrifugation. Machine dehydration to prepare plant fiber filter mud for later use;

[0080] (2) Preparation of hybrid fiber filler modified by mixing rice husk plant fiber mud and nano-silica colloidal solution. In Examples 1-6, the modified hybrid fiber filler is prepared through the following technical scheme:

[0081] a. Take 100 liters of industrial sodium silicate solution with a modulus of 3.0 and a mass fraction of 10% of the prepared silicon dioxide, add it to the reaction ke...

Embodiment 1

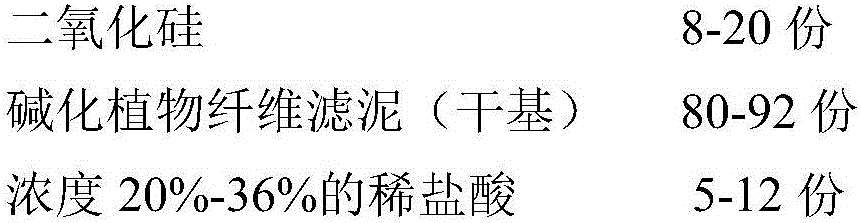

[0096] Formula is as follows (parts by weight):

[0097]

[0098] The preparation process is as follows:

[0099] First, use a high-speed mixer to mix the above-mentioned raw materials weighed by weight evenly to obtain a uniformly mixed material; then, put the mixed material into a three-screw extruder for melt blending, and the temperature of each section of the barrel is 120-190 ℃, the rotating speed of the main screw is 110r / min, extrusion, strand drawing, air cooling, pelletizing, sealing and packaging to obtain polyolefin composite materials for injection molding.

Embodiment 2

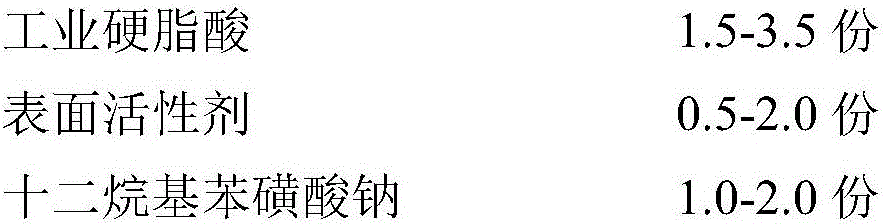

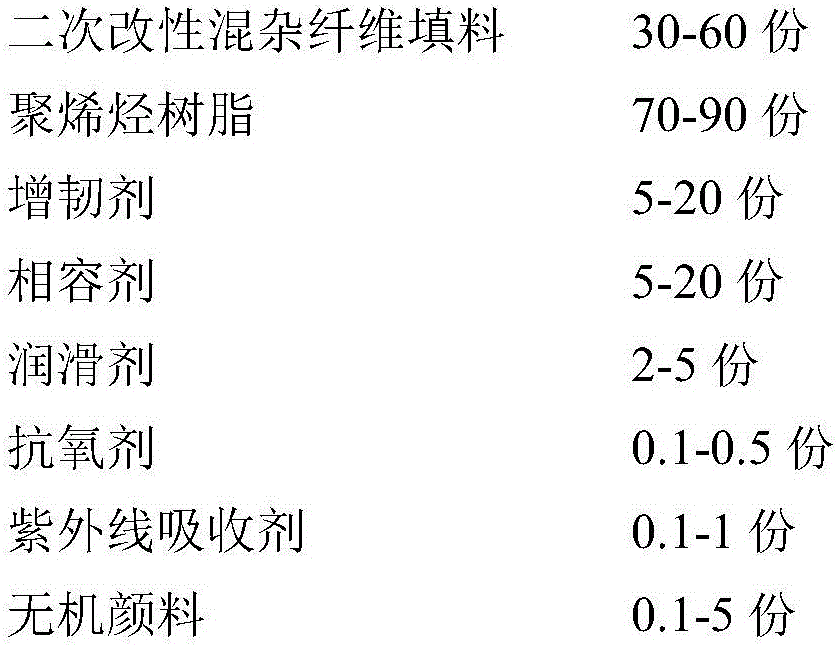

[0101] Formula is as follows (parts by weight):

[0102]

[0103]

[0104] According to the above formula, the raw materials are weighed in parts by weight, and the preparation process is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com