Weaving of core-spun yarn

A technology of core-spun yarn and core yarn, which is applied in textiles and papermaking, yarn, fiber processing, etc., and can solve problems such as high insulation and serious static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

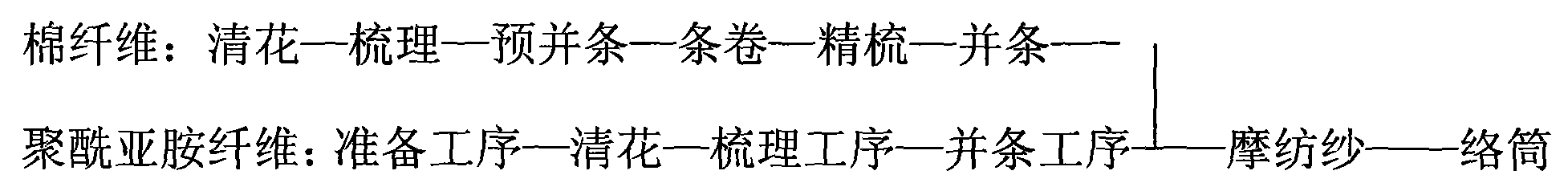

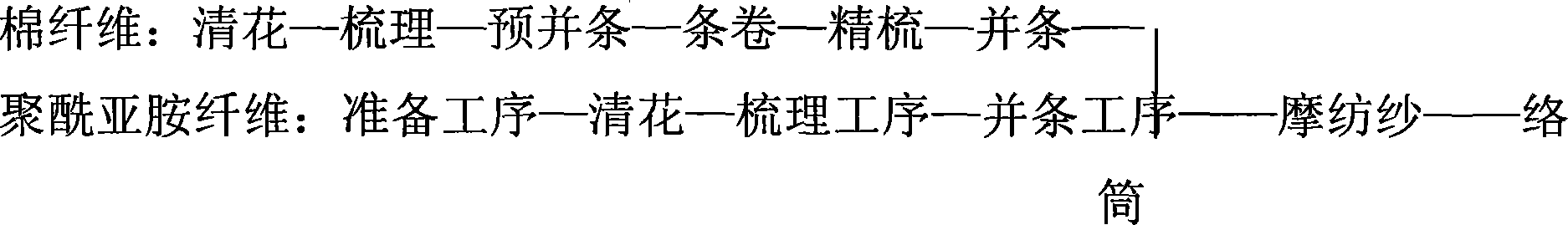

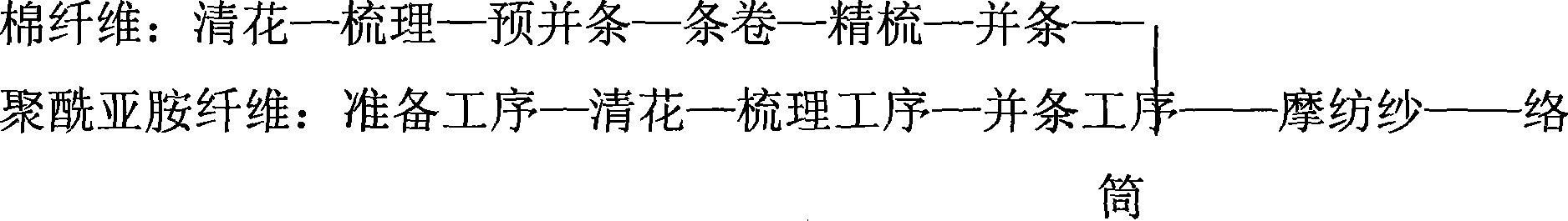

[0012] The preparation method of the present invention is the following steps:

[0013] Choose oil agent or antistatic agent, spray evenly on the fiber pile, the dosage is 6-9%, and pile up for more than 24 hours. Because the fiber is in good order and there are few large impurities, it is mainly to open and remove impurities. Appropriate blowing, pay attention to the use of airflow when shooting miscellaneous, reduce cotton nodding, cleaning beater below 500r / min, carding cylinder speed 300-360r / min, licker-in roller speed 650-700r / min, doffer speed 17-19r / min, The sliver weight is 43-45g / m, the combed weight is 16-17g / 5m, and then the cotton fiber is cleaned, carded, pre-drawn, sliver, combed, drawn in the normal spinning process, and combed during blowing Needle beater speed is 480r / min, comprehensive beater speed is 820r / min, carding cylinder speed is 330r / min, licker-in speed is 850r / min, two drawing frames are adopted, core-spun yarn spinning process is in friction spinn...

Embodiment 1

[0016] Ingredients: 70% polyimide functional fiber, 30% natural cotton fiber;

[0017] Preparation:

[0018] Choose oil agent or antistatic agent, spray evenly on the fiber pile, the dosage is 6-9%, and pile up for more than 24 hours. Because the fiber is in good order and there are few large impurities, it is mainly to open and remove impurities. Appropriate blowing, pay attention to the use of airflow when shooting miscellaneous, reduce cotton nodding, cleaning beater below 500r / min, carding cylinder speed 300-360r / min, licker-in roller speed 650-700r / min, doffer speed 17-19r / min, The sliver weight is 43-45g / m, the combed weight is 16-17g / 5m, and then the cotton fiber is cleaned, carded, pre-drawn, sliver, combed, drawn in the normal spinning process, and combed during blowing Needle beater speed is 480r / min, comprehensive beater speed is 820r / min, carding cylinder speed is 330r / min, licker-in speed is 850r / min, two drawing frames are adopted, core-spun yarn spinning proces...

Embodiment 2

[0020] Ingredients: 60% polyimide functional fiber, 40% natural cotton fiber, the preparation method is the same as that of Example 1.

[0021] In summary, the core-spun yarn of the present invention uses polyimide functional fibers and natural cotton fibers as raw materials, has a wide temperature range, and the addition of natural fibers improves cloth performance, and the friction spinning process is short and increases The dyeability of the yarn increases the production value of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com