Safe, environment-friendly and high-performance electrochromic film and preparation method thereof

An electrochromic, safe and environmentally friendly technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of limited application of aqueous electrolytes, small pore size, unsuitable for multivalent cation deintercalation, etc., to increase reactive sites. , Prevent agglomeration, reduce the effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a safe, environment-friendly and high-performance electrochromic material, the specific steps are as follows:

[0029] Step 1 Prepare the precursor solution at room temperature: Take 0.083g of terephthalic acid (0.5mmol) and 0.119g of nickel chloride hexahydrate (0.5mmol) and dissolve them in 20ml of N,N-dimethylformamide under stirring at room temperature. 1 mL of ultrapure water was slowly added to the solution during stirring.

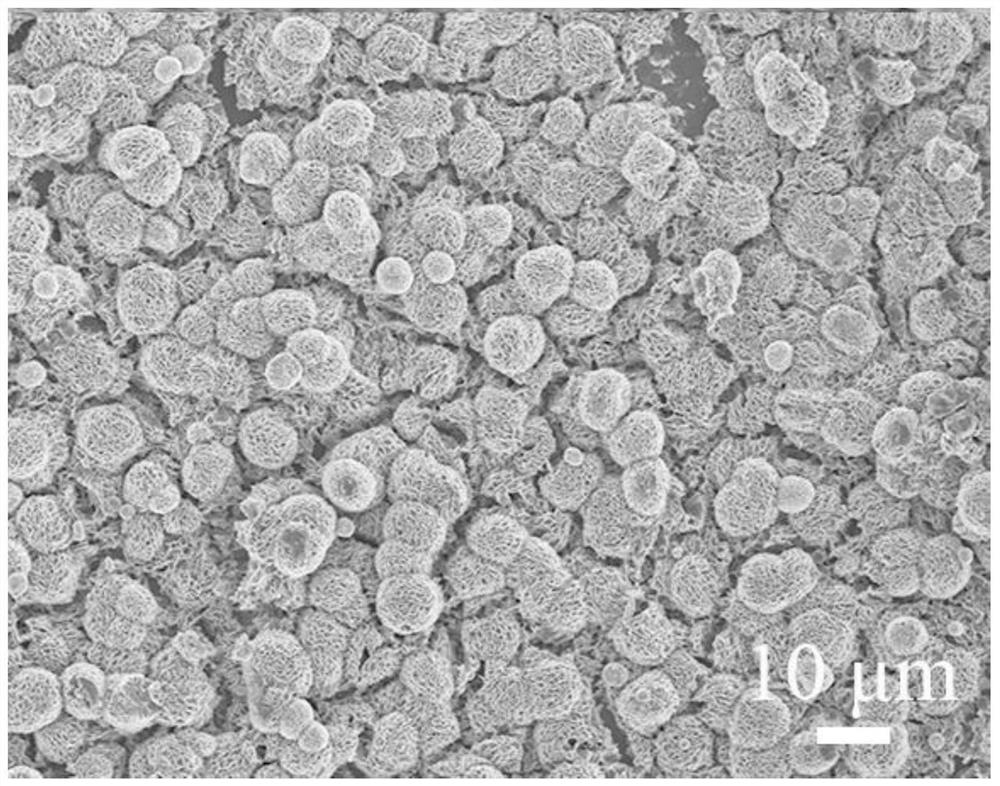

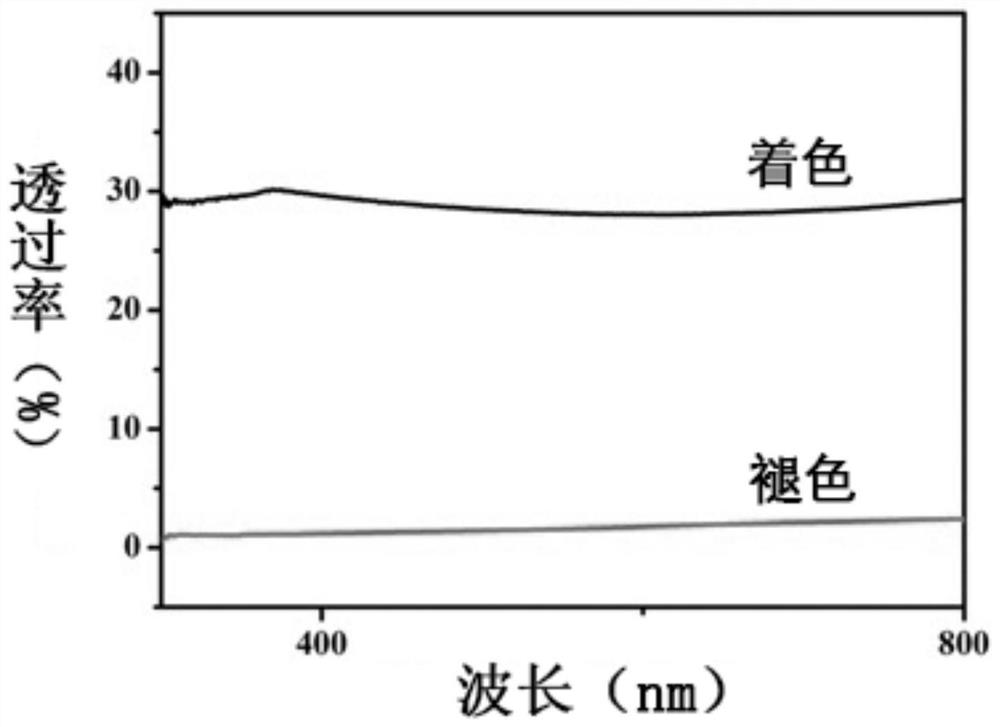

[0030] Step 2 Transfer the precursor solution obtained in step 1 to a stainless steel autoclave, soak and fix 2*2.5 ITO conductive glass vertically in the precursor solution for 3 hours at 120°C, and cool to room temperature after the reaction. After washing, the sample was heated to 450°C in an argon atmosphere, and kept at 450°C for 120 minutes, then replaced with air for argon, and continued to heat for 30 minutes, the film changed from light green to light brown, and the performance of the test was obtained. NiO el...

Embodiment 2

[0033] Step 1 Prepare the precursor solution at room temperature: Take 0.083g of terephthalic acid (0.5mmol) and 0.119g of nickel chloride hexahydrate (0.5mmol) and dissolve them in 20ml of N,N-dimethylformamide under stirring at room temperature. 1 mL of ultrapure water was slowly added to the solution during stirring.

[0034] Step 2 Transfer the precursor solution obtained in step 1 to a stainless steel autoclave, soak and fix 2*2.5 ITO conductive glass vertically in the precursor solution for 3 hours at 120°C, and cool to room temperature after the reaction. After washing, the sample was heated to 450°C in an argon atmosphere, and kept at 450°C for 120 minutes, then replaced with air for argon, and continued to heat for 30 minutes, the film changed from light green to light brown, and the performance of the test was obtained. NiO electrochromic film.

[0035] In step 3, the thin film obtained in step 2 is used as the working electrode, the platinum wire is used as the cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com