Manufacture method of bamboo plate

A production method and bamboo board technology, which are applied in the direction of wood compression, wood treatment, and manufacturing tools, etc., can solve the problems of uneven surface of the main board, reduce the thickness of the main board, increase the processing process, etc. The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

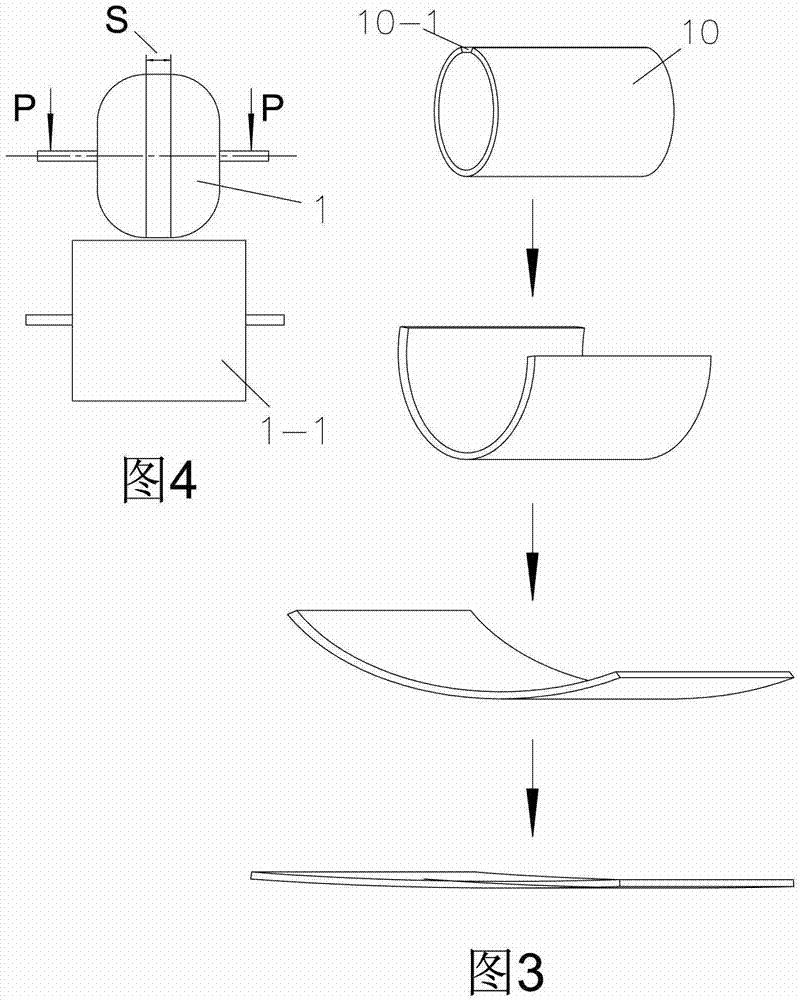

[0023] The bamboo wall consists of a thin layer of bamboo green and bamboo yellow on the outer surface, except for the outer and inner nodes of the bamboo tube. Therefore, the thickness of a single bamboo board after flattening is usually smaller than the thickness of the bamboo wall.

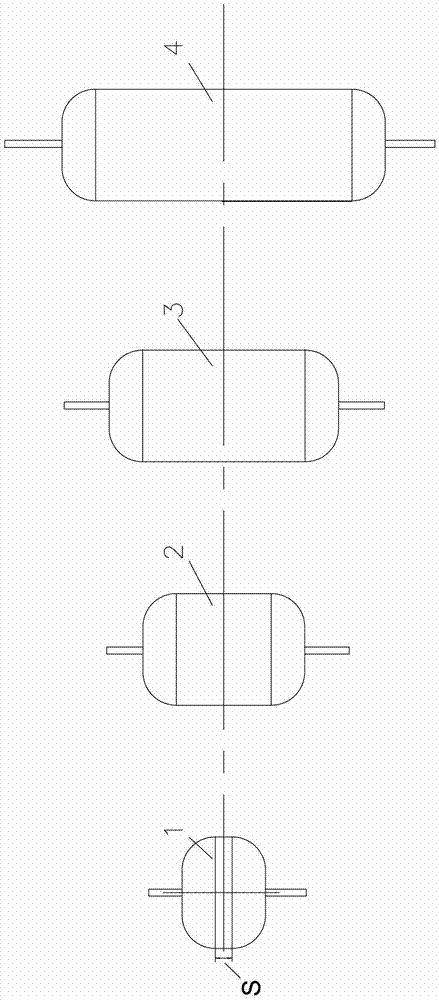

[0024] The manufacturing method of the bamboo board provided by the present invention is carried out according to the following steps:

[0025] 1) Saw the bamboo into a bamboo tube with a length of more than 0.3 meters,

[0026] 2) Remove the outer section of the bamboo tube (the protrusion surrounding the outer circumferential surface of the bamboo section), usually with a plane or a mechanical belt knife);

[0027] To remove the inner section of the bamboo tube (also known as the bamboo section), usually a metal rod can be used to poke it; or a mechanical belt knife can be used to remove the inner section.

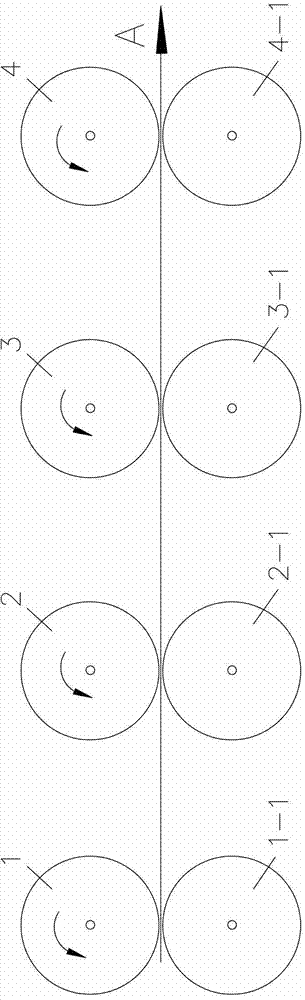

[0028] 3) Saw a slot through the bamboo wall along the longitudinal direction of the bamboo tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com