Large floating liquefied natural gas production, storage and unloading device

A technology of liquefied natural gas and liquefied petroleum gas, which is applied in the direction of transportation and packaging, bulk cargo, ships, etc., and can solve problems such as huge investment and ineffective development of natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

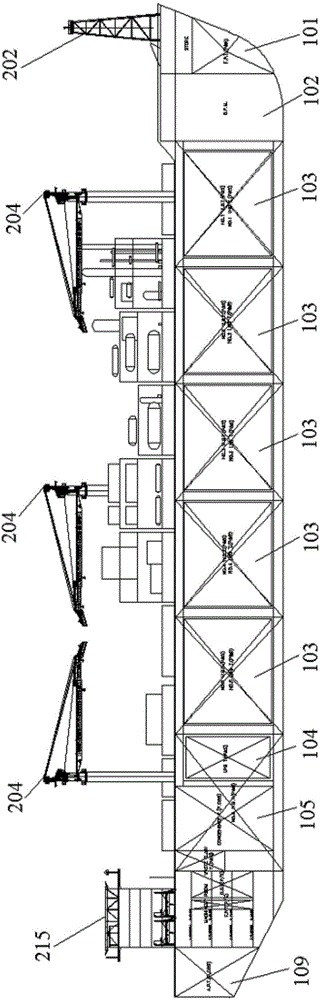

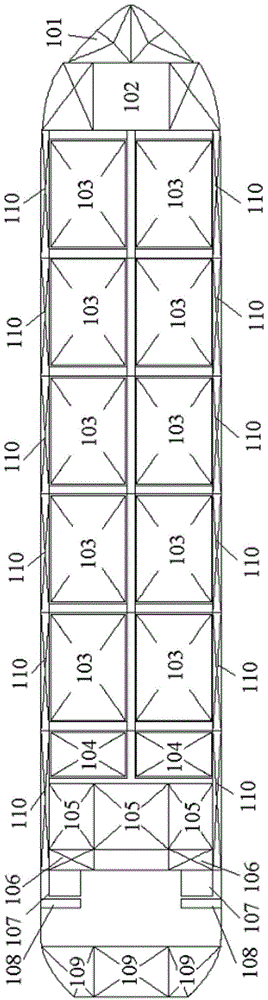

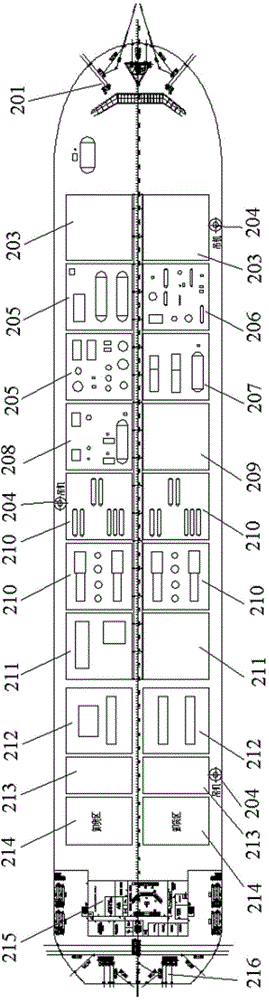

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a hull 100 and FLNG topsides 200 arranged on the deck of the hull. Among them, a pair of forepeak tanks 101 as ballast water tanks are arranged symmetrically on the left and right sides of the bow of the hull 100, with a capacity of 3200m 3 . A single-point cabin 102 is arranged at the rear of the fore peak tank 101, and an inner turret (not shown in the figure) of the inner turret single-point system is installed in the single-point cabin 102 . Five pairs of LNG tanks 103 are symmetrically arranged on the starboard and starboard sides at the rear of the single point tank 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com