LNG tank container reloading ship

A technology of tank container and hull, applied in the direction of hull, ship construction, ship accessories, etc., can solve the problems of small loading capacity of bunkering ships, low filling efficiency of gas station, complicated procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

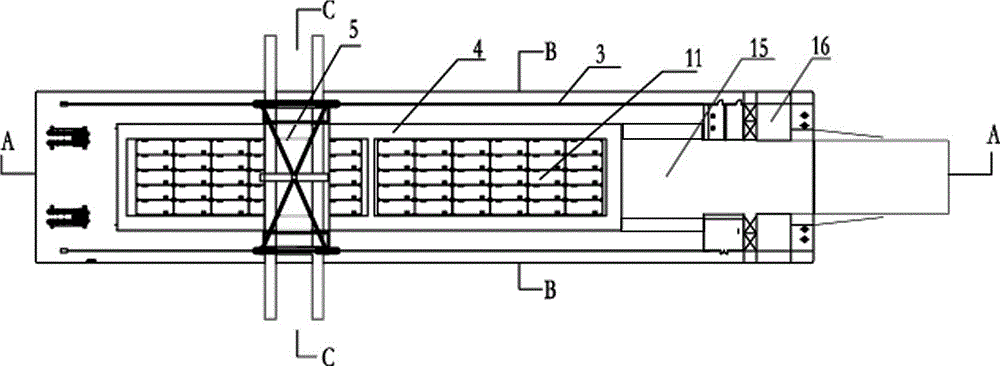

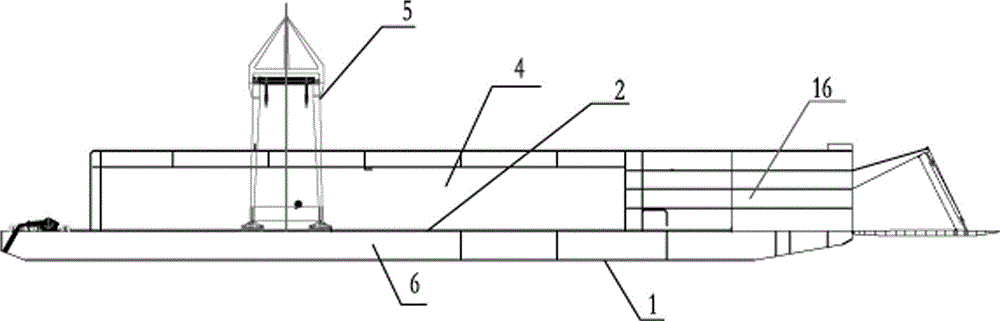

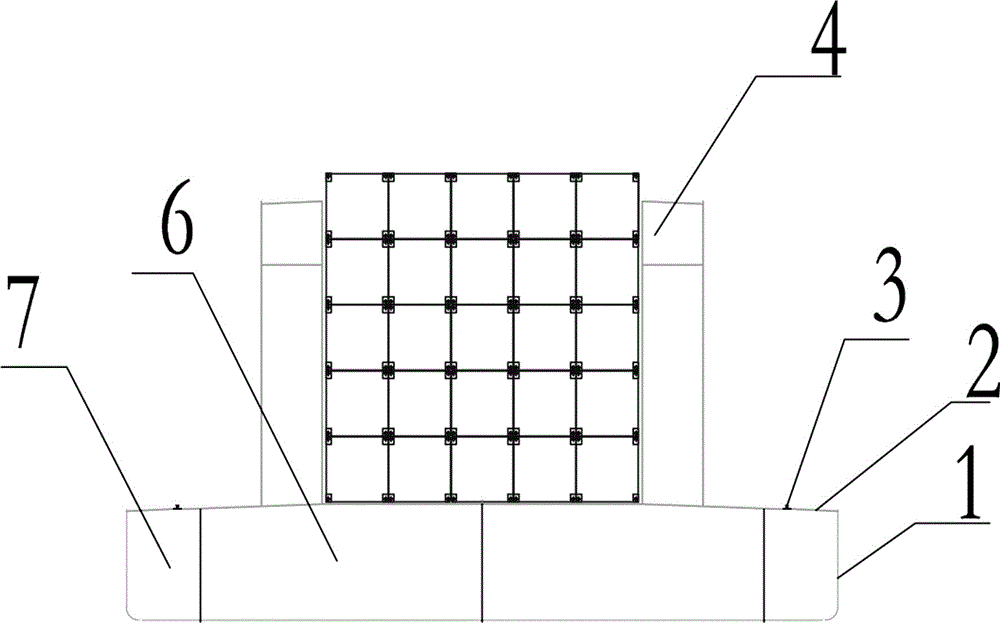

[0028] As in 1, 2, and 4, a LNG tank container reloading ship includes a hull 1, the upper surface of the hull 1 is provided with a main deck 2, and the main deck 2 is provided with two parallel tracks 3. 3 is provided with an enclosed dock wall-type protective wall 4, and the gantry bridge type LNG tank container special crane 5 runs along two tracks 3 (stop piers are set at both ends of the track to prevent the gantry bridge type LNG tank container special crane 5 from slide out of the track), preferably, the length of the dock wall type protective wall 4 is less than the length of the track 3, the front end of the main deck 2 is provided with a vehicle loading and unloading area 15, the docking wall type protective wall 4 is connected to the vehicle loading and unloading area 15, at least part of the vehicle loading and unloading area Zone 15 is between two side tracks 3;

[0029] On both sides of the vehicle loading and unloading area 15, a boat room 16 is respectively pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com