Full-automatic water floating garbage and aquatic plant salvage compression ship

A technology of floating on the water surface and aquatic plants, applied in the direction of hull, ship construction, and some cabins in the hull, can solve the problems of increased weight, increased fuel consumption, and increased work costs, so as to increase loading capacity, reduce unloading frequency, and avoid fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

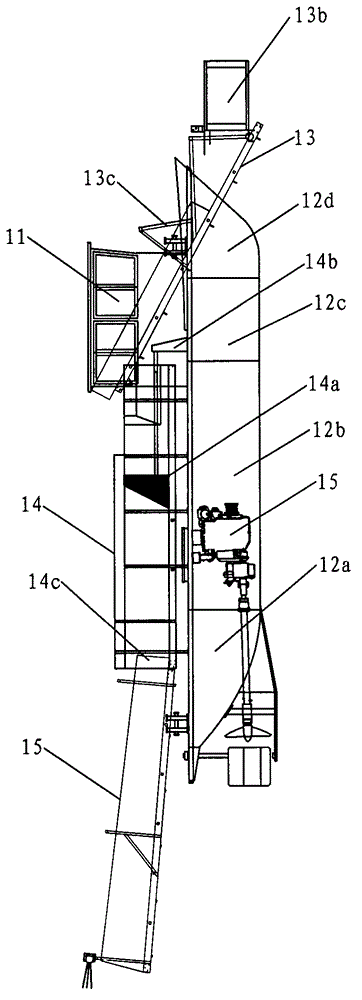

[0017] Such as figure 1 As shown, the full-automatic water surface floating garbage and aquatic plant salvage compression ship includes a driver's cab 11, a cabin and a deck, and three watertight transverse walls are arranged in the cabin, and these three watertight transverse walls divide the cabin into an empty cabin 12a, an engine room 12b, and an empty cabin. Cabin 2 12c and fore peak tank 12d, the fore peak tank 12d is obliquely cut to form a double head, and a waterweed collection device 13 is installed in the middle of the double head, and a compression storage transfer cabin 14 and a storage tank are sequentially arranged on the deck from bow to stern Unloading cabin 15.

[0018] Compression type storage transfer cabin 14 comprises conveyer belt one and compression de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com