Anti-rolling ship

A ship and rolling technology, which is applied in the field of anti-rolling ships, can solve the problems of power consumption, excessive cost and space, and insufficient anti-rolling performance of the bilge keel, so as to achieve the effect of reducing ship's rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In the description with reference to the drawings, the same or corresponding components are assigned the same or corresponding reference numerals, and repeated descriptions are omitted.

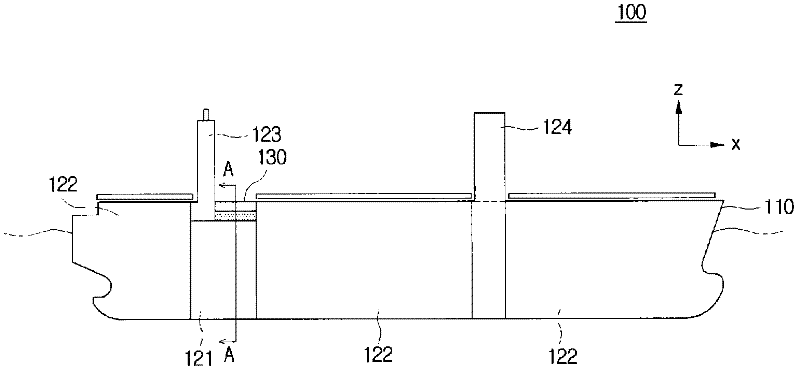

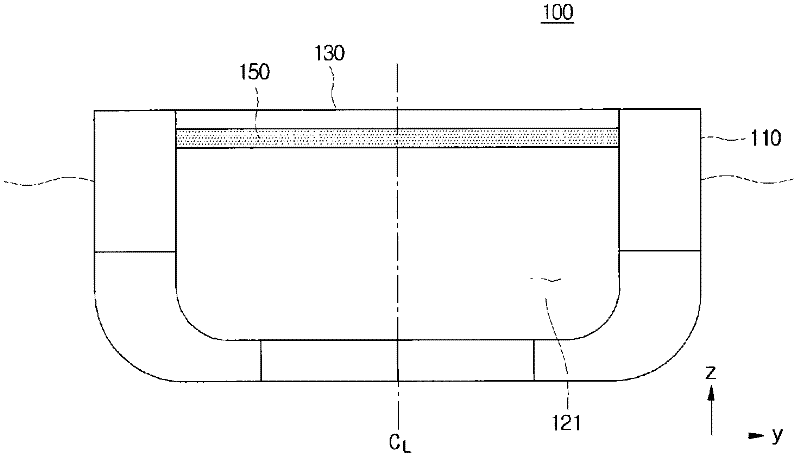

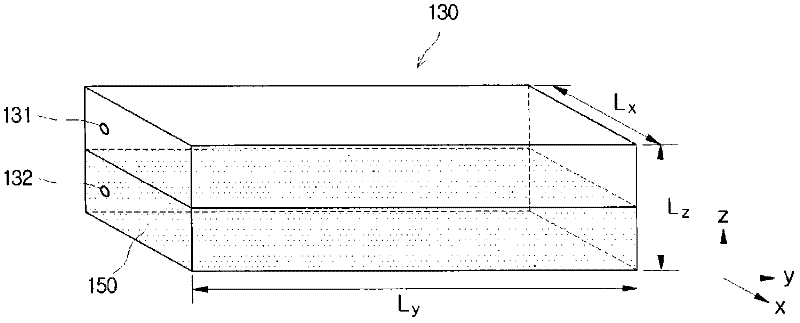

[0061] figure 1 is a side view of a ship according to an embodiment of the present invention, figure 2 yes figure 1 A-A sectional view in . here, figure 1 with figure 2The shown coordinate system is an orthogonal coordinate system, and the x-axis is defined as the length direction of the hull constituting the aforementioned ship; the y-axis is defined as the width direction of the hull; and the z-axis is defined as the height direction of the hull.

[0062] Such as figure 1 As shown, the ship 100 related to this embodiment includes a hull 110 and a cabin 130 partially containing fluid inside. The ship 100 related to this embodiment includes but not limited to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com