Suspension structure and connecting mode of bridgeless automobile

A suspension and frame technology, which is applied in the field of suspension structure and connection method of bridgeless vehicles, can solve the problems of left and right shaking of the vehicle body, tail flicking, lack of steering centrifugal force and weight support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

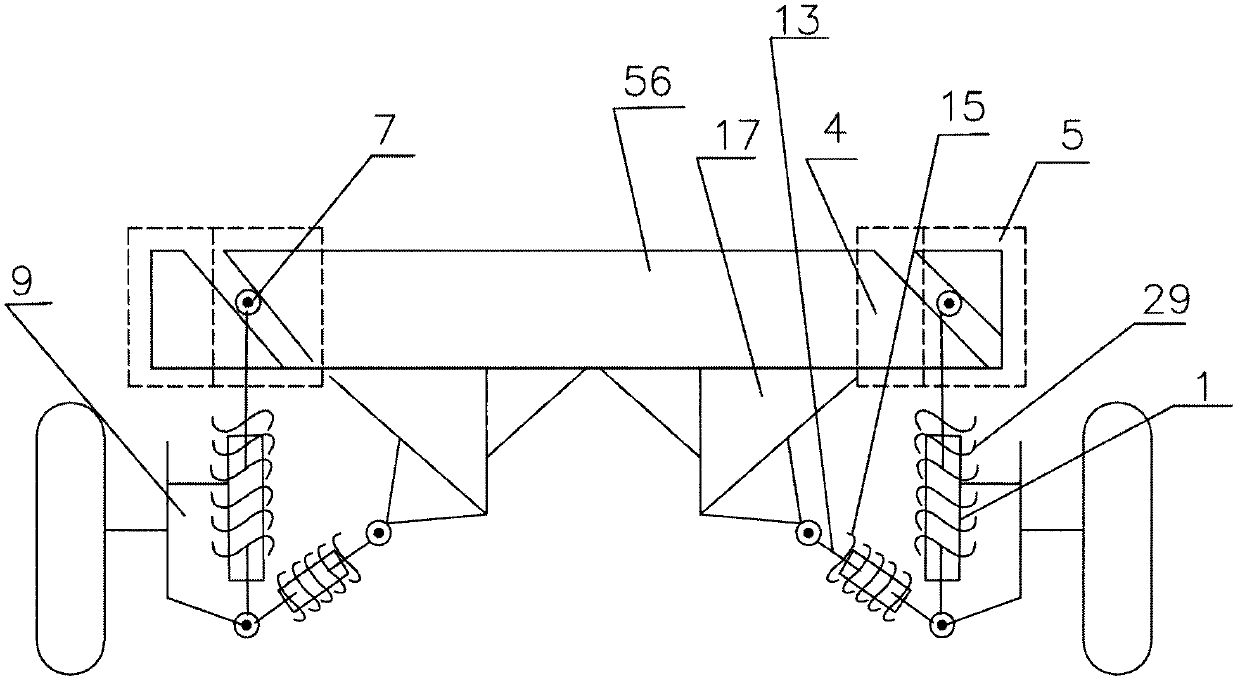

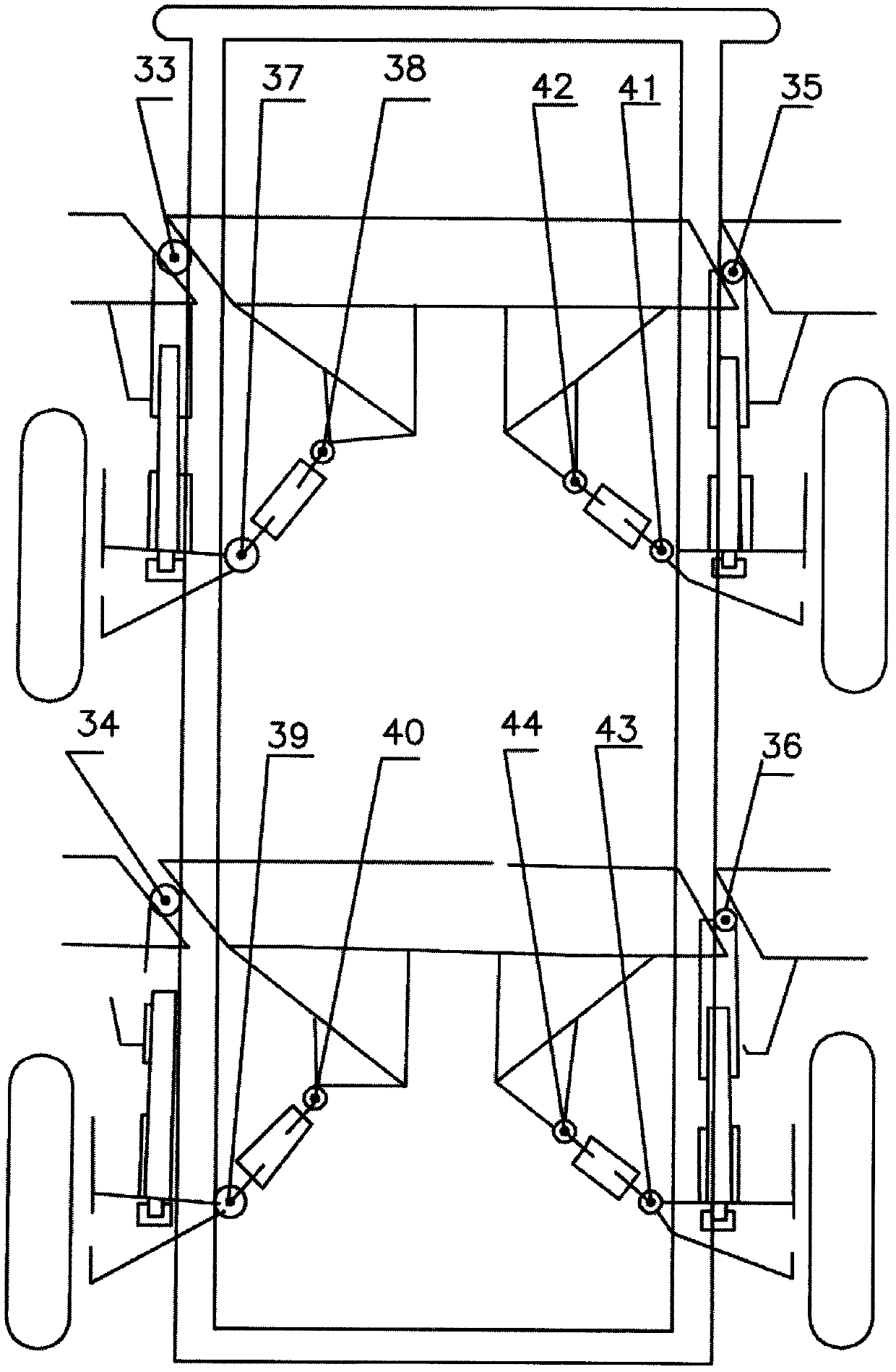

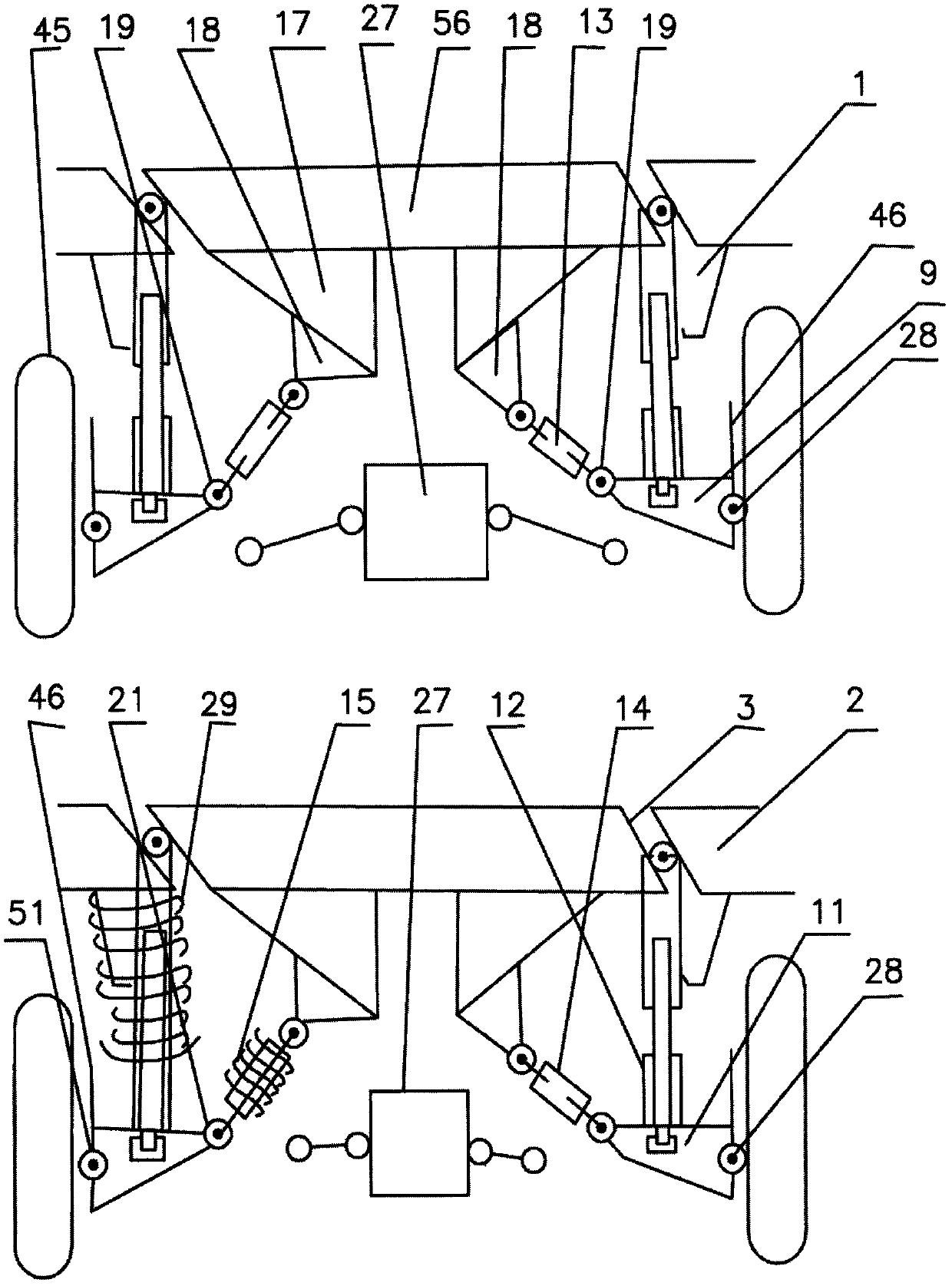

[0045] Such as Figure 1 to Figure 7 As shown, a suspension structure and connection method of a bridgeless automobile, wherein the main components and connection method in the suspension structure of a bridgeless automobile include a conical hydraulic shock absorber 1, a 45-degree slope suspension upper end interface 2, 45-degree slope frame interface 3, frame hinge shaft connecting plate 4, suspension hinge shaft connecting plate 5, suspension positioning bushing 6, suspension hinge shaft 7, fastening screw 8, front wheel support assembly 9, front Suspension fixing and steering rotation auxiliary connection device 10, rear wheel support assembly 11, rear suspension connection and fixing device 12, front wheel lateral hydraulic support stabilizer bar 13, rear wheel lateral hydraulic support stabilizer bar 14, wheel lateral support return spring 15. Frame or load-bearing body 16. Subframe 17. Horn support seat assembly 18. Front wheel support assembly lateral hydraulic support...

Embodiment 2

[0052] This embodiment is further limited on the basis of Embodiment 1: as a technical solution with a simple structure and easy processing, manufacturing and assembly, the first to twelfth hinges are hinged and rotated, and the hinge shaft 7 The length direction of , 24 is consistent with the length direction of the vehicle, that is, the length direction of the hinge shaft is parallel to the length direction of the vehicle frame or load-bearing body 16, and the axis direction of the cross shaft 22 and the connection end of the front wheel lateral hydraulic support stabilizer bar is hinged with the suspension The shaft 7 is in the same length direction as the hinge shaft 24 of the front wheel lateral hydraulic support stabilizer bar. Since the small journal section of the suspension hinge shaft is in direct contact with the surface of the needle roller bearing, the machining accuracy and heat treatment hardness of the surface should be the same as that of the inner bearing. Cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com