A high-strength support plate

A support plate, high-strength technology, used in rocket launchers, offensive equipment, weapon types, etc., can solve problems such as easy to get stuck, low strength, strong pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

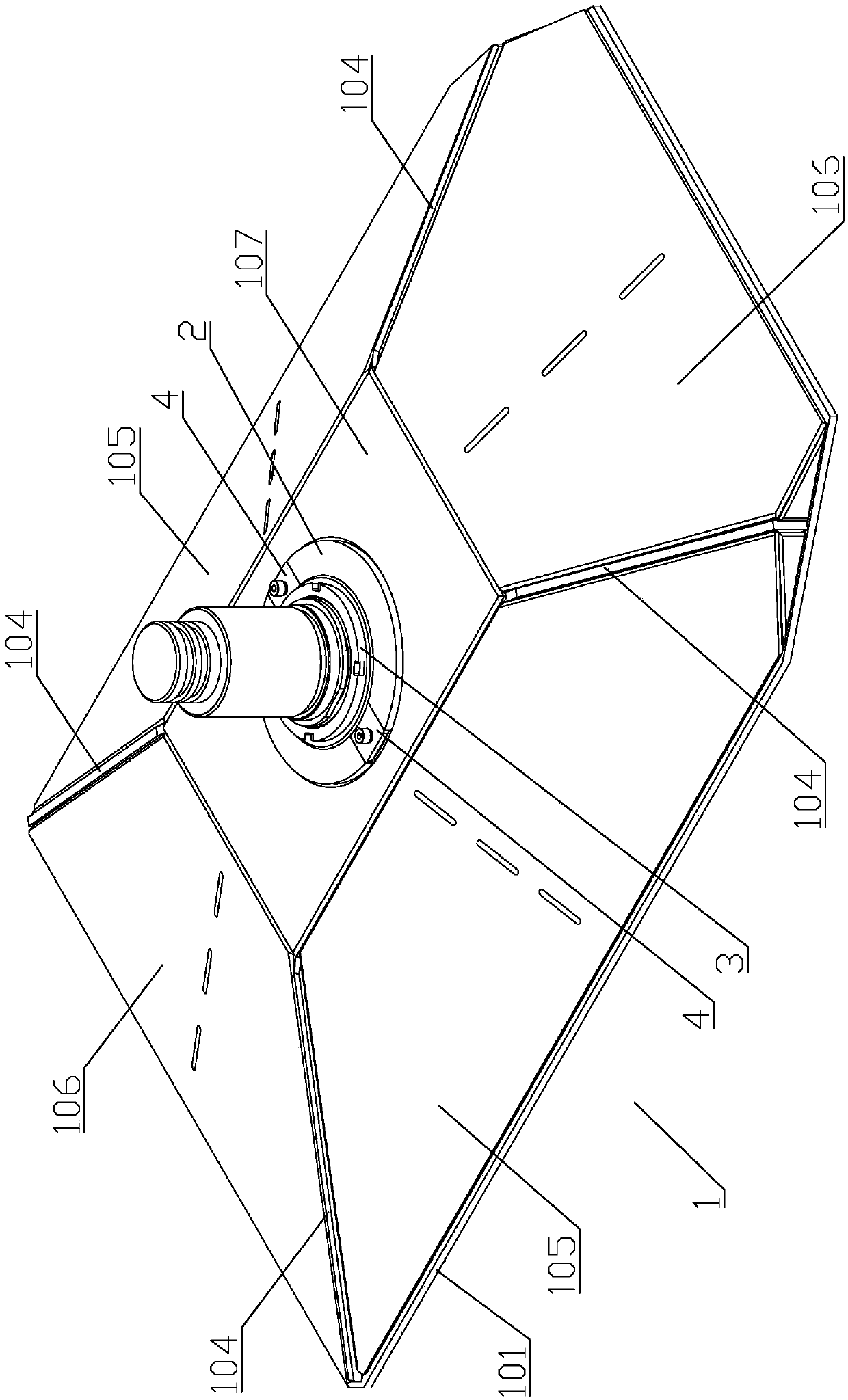

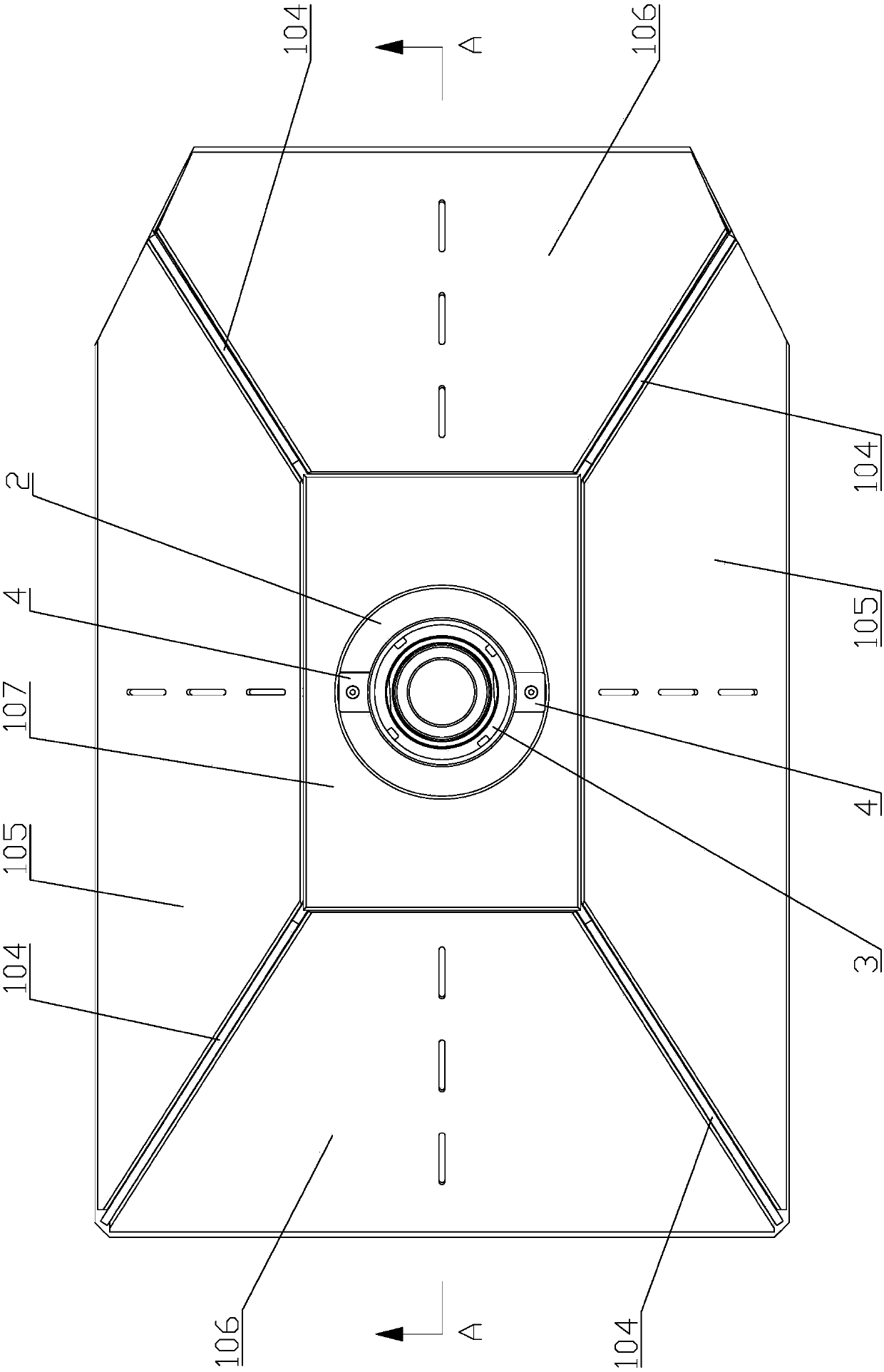

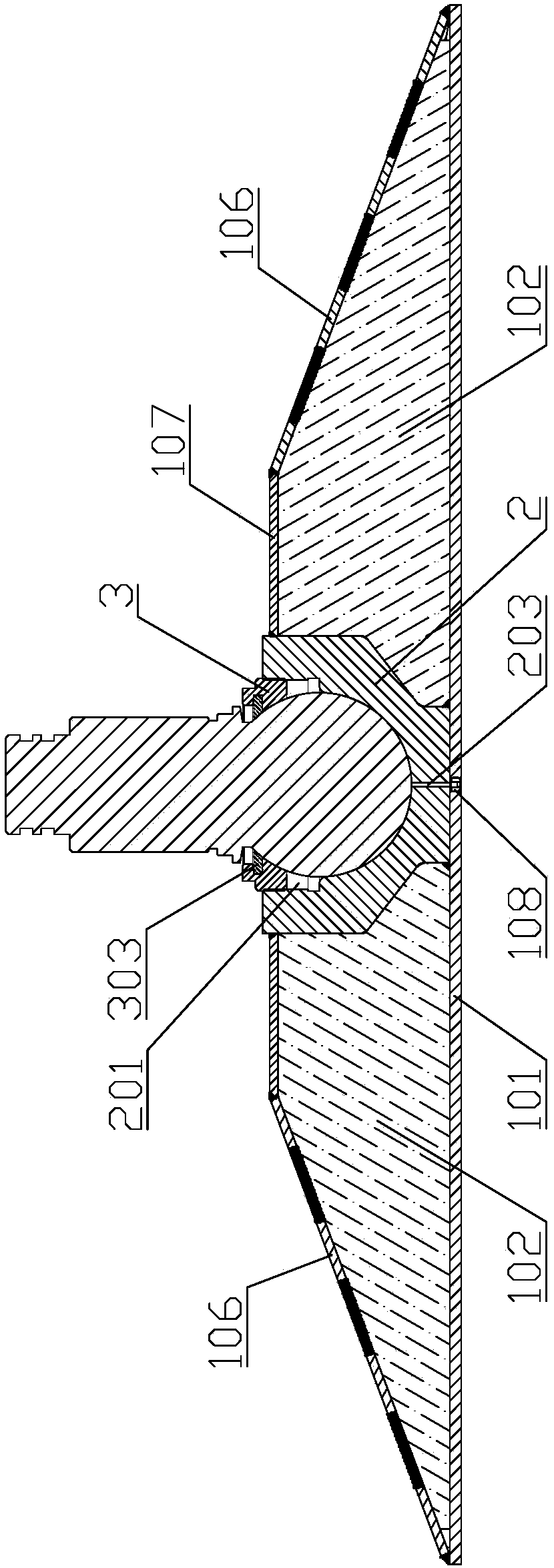

[0027] like Figure 1 to Figure 14Shown is a specific embodiment of a high-strength support disc of the present invention, which generally includes a support seat 1 and a support shaft 2 . Wherein, the support seat 1 specifically includes a bottom plate 101, two transverse rib plates 102, two longitudinal rib plates 103, four diagonal rib plates 104, two large cover plates 105, two small cover plates 106 and an upper cover plate 107 . Let the support shaft 2 be vertically fixed on the middle part of the upper side of the bottom plate 101, and the fixing method can be realized by welding. The two transverse stiffeners 102 are perpendicular to the upper side of the bottom plate 101 and symmetrically distributed on both sides of the support shaft 2 along the transverse direction, and the two transverse stiffeners 102 are welded to the bottom plate 101 and the support shaft 2 . Let the two longitudinal stiffeners 103 be perpendicular to the upper side of the bottom plate 101 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com