Novel internal single-action mechanism of drilling tool

A single-action mechanism and drilling tool technology, used in earth-moving drilling, extraction of undisturbed core devices, etc., can solve the problems of easily damaged shafts and bearings on the shaft, affecting the strength of the shaft, friction interference, etc., to protect the shaft and bearings, extend the Long service life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

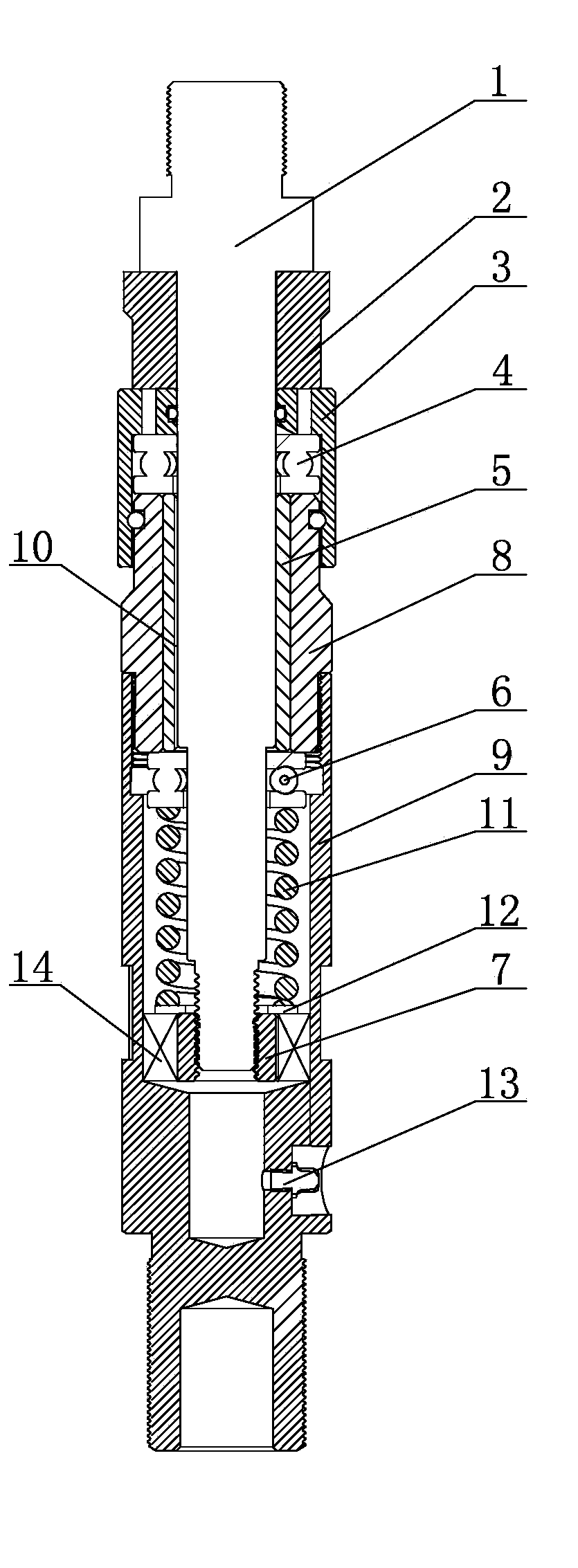

[0011] See figure 1 , the present invention includes a shaft 1, the outer peripheral surface of the shaft 1 is sequentially sleeved with a first joint 2, a bearing seat 3, an upper bearing 4, a shaft sleeve 5, a lower bearing 6 and a lock nut 7, and the shaft sleeve 5 Assembled in the second joint 8, one end of the second joint 8 is threaded with the bearing seat 3, the other end of the second joint 8 is threaded with the inner pipe 9, the lower bearing 6 and the shaft section of the shaft 1 below the lower bearing 6 are located in the inner Inside the tube 9, the inner wall of the shaft sleeve 5 is evenly distributed with oil grooves 10 along the axial direction, the shaft section between the lower bearing 6 and the lock nut 7 is provided with a spring 11 and a washer 12, and the inner tube 9 is provided with radial oil. The hole 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com