High-strength reinforced belt and manufacturing method thereof

A reinforced belt, high-strength technology, applied in the field of high-strength reinforced belt and its production, can solve the problems of unreachable, reduced processing efficiency, affecting the quality of the row body, etc., and achieves the effect of avoiding oxidation and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

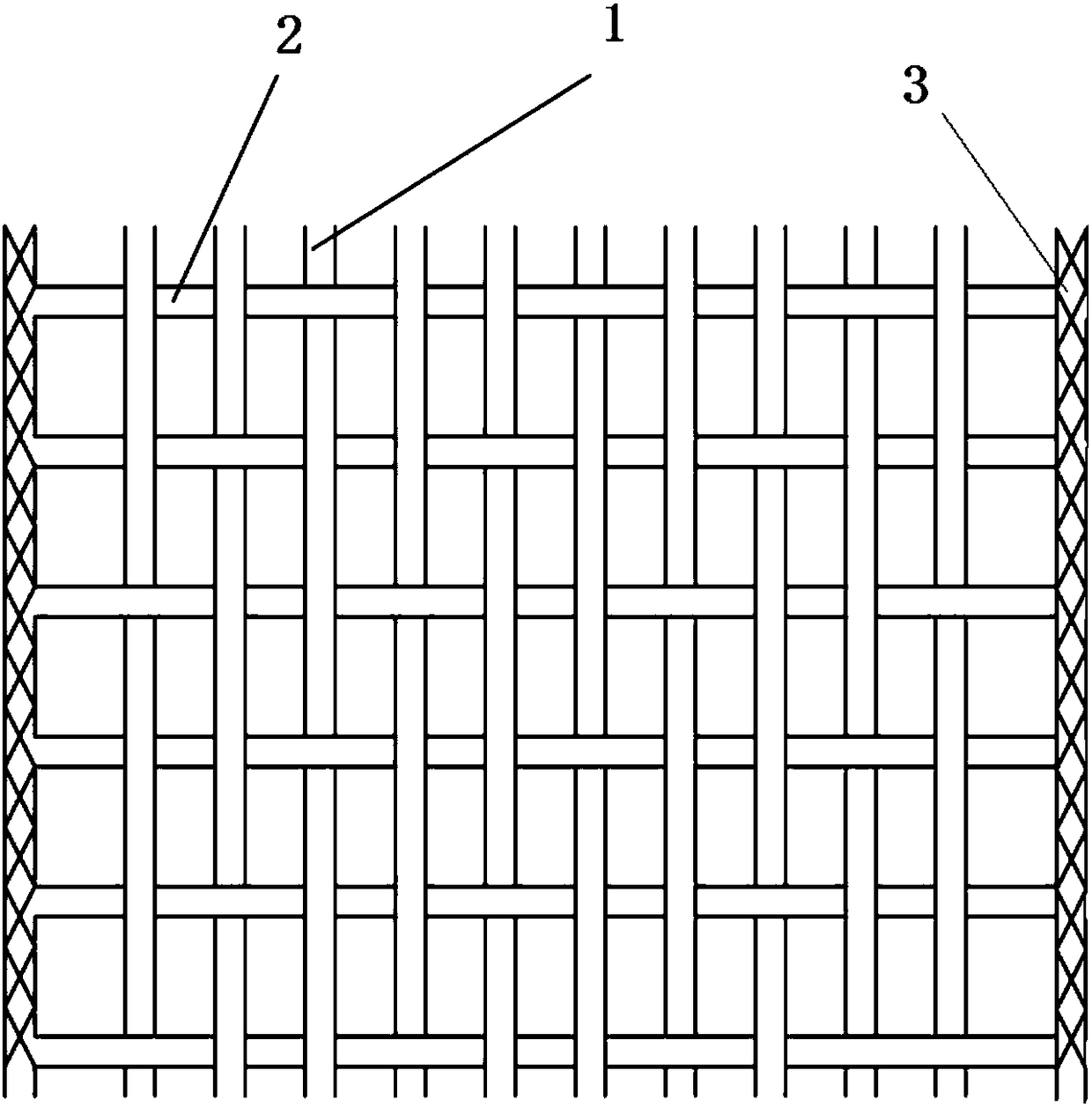

[0028] like Figure 1 to Figure 4 As shown, the high-strength reinforced belt of the present embodiment includes a plurality of radial bundled hard filaments 1, a plurality of weft polypropylene filaments 2 and radial side lines 3, and each radial bundled stiff filament 1 is arranged in parallel. The radial beam-shaped hard filament 1 and the weft-direction polypropylene filament 2 are interspersed to form a mesh body, and the polypropylene filament is used as the radial edge 3 placed on both sides of the radial beam-shaped rigid filament 1, and each weft polypropylene filament The two ends of the filament 2 are fixedly connected with the radial side line 3 respectively, and the radial bundle hard filament 1 is made of polypropylene with a mass ratio of 88% to 94%, polyethylene with a mass ratio of 5% to 10%, and a mass ratio of 5% to 10%. 0.5% to 1% plastic anti-aging agent, 0.5% to 1% plastic reinforcing agent by mass, radial beam-like hard filaments obtained after melting, ...

Embodiment 2

[0029] Embodiment 2 The production method of the high-strength reinforced belt of the present embodiment comprises the following steps:

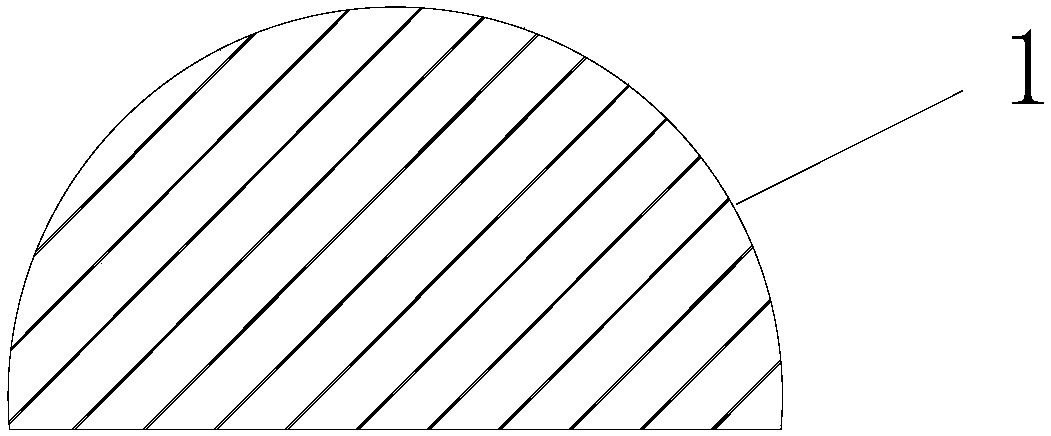

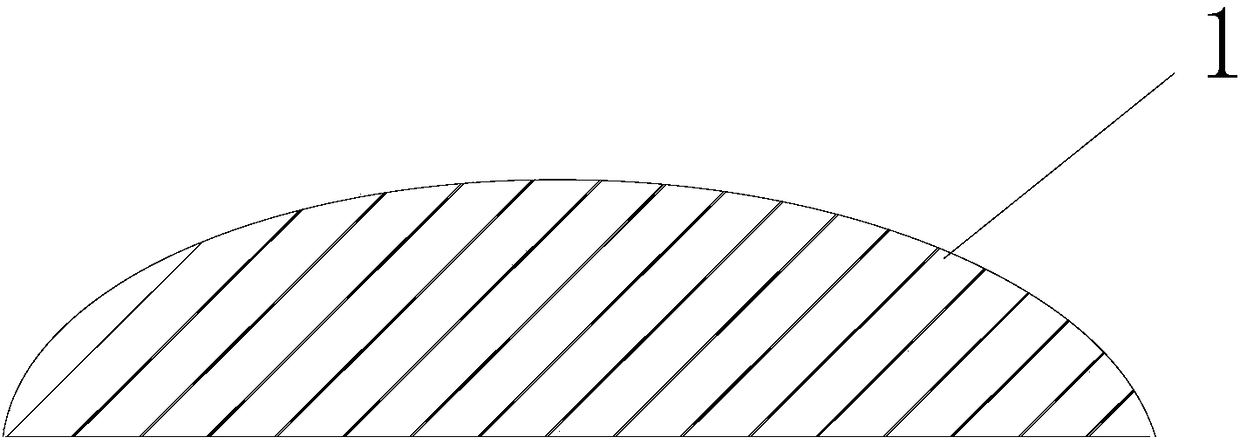

[0030] A. Heat and melt 88% polypropylene by mass, 10% polyethylene by mass, 1% plastic anti-aging agent by mass, and 1% plastic reinforcing agent by mass, and then extrude after mixing Extruded to obtain bundle-like hard filaments, the cross-section of the die of the extruder is hemispherical (or semi-oblate spherical), so that the cross-section of the extruded bundle-like hard filaments is correspondingly hemispherical (or semi-oblate spherical) .

[0031] B. Use a wire drawing machine to stretch the extruded bundled hard filaments, place the stretching machine in a sealed space, and feed nitrogen gas with a temperature of 100°C into the sealed space to heat the bundled hard filaments to Make bundles of stiff filaments easy to stretch.

[0032] C. Keep the wire drawing machine still after stretching the bundled hard wire to a preset leng...

Embodiment 3

[0038] Embodiment 3 The production method of the high-strength reinforced belt of the present embodiment comprises the following steps:

[0039] A. Heat and melt 94% polypropylene by mass, 5% polyethylene by mass, 0.5% plastic anti-aging agent by mass, and 0.5% plastic reinforcing agent by mass, and then extrude after mixing Extruded to obtain bundle-like hard filaments, the cross-section of the die of the extruder is hemispherical (or semi-oblate spherical), so that the cross-section of the extruded bundle-like hard filaments is correspondingly hemispherical (or semi-oblate spherical) .

[0040] B. Use a wire drawing machine to stretch the extruded bundled hard filaments, place the stretching machine in a sealed space, and feed nitrogen gas with a temperature of 80°C into the sealed space to heat the bundled hard filaments to Make bundles of stiff filaments easy to stretch.

[0041] C. Keep the wire drawing machine still after stretching the bundled hard wire to a preset le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com