A multi-station robot production line and production method

A robot and production line technology, which is applied in the production of multi-station robot production lines and in the field of multi-station robot production lines, can solve problems such as low production efficiency, and achieve the effects of saving manpower, improving processing efficiency, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

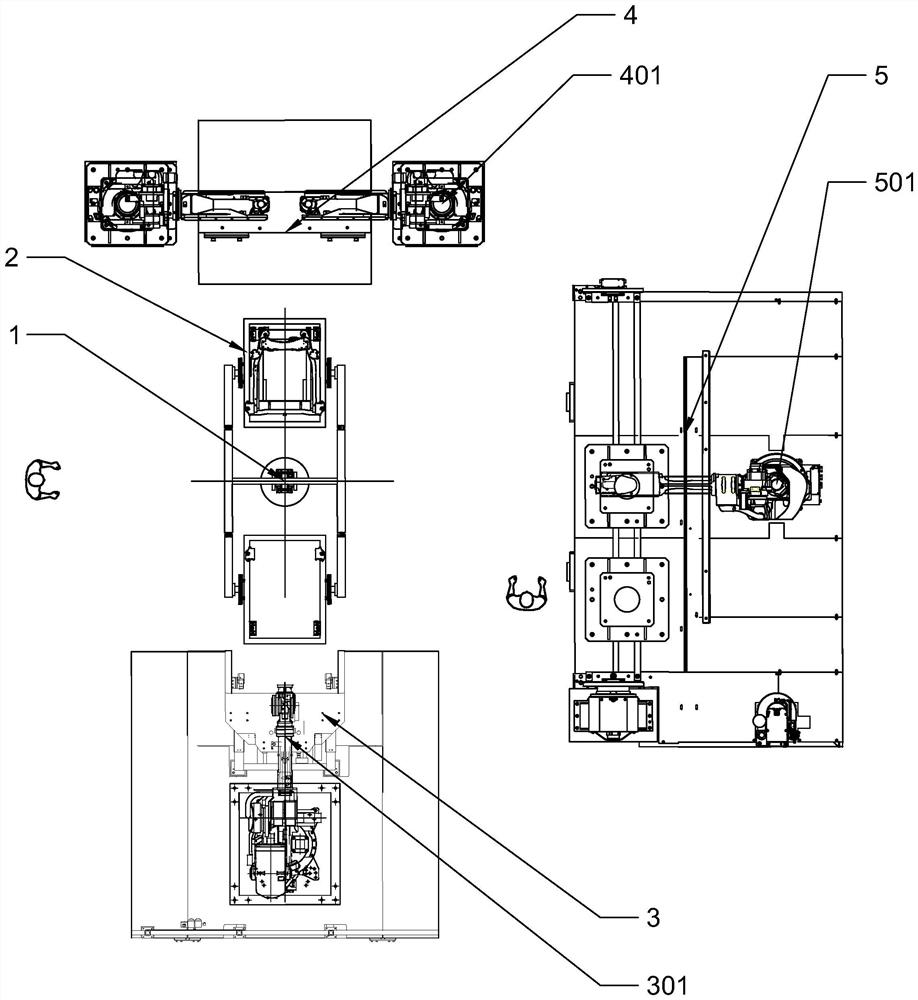

[0027] Such as figure 1 As shown, in a multi-station robot production line of the present invention, the spot welding worktable 3 is arranged on the front side of the rotary mechanism 1, the arc welding workbench 4 is arranged on the rear side of the rotary mechanism 1, and the repair welding workbench 5 is arranged on the rotary Right side of institution 1.

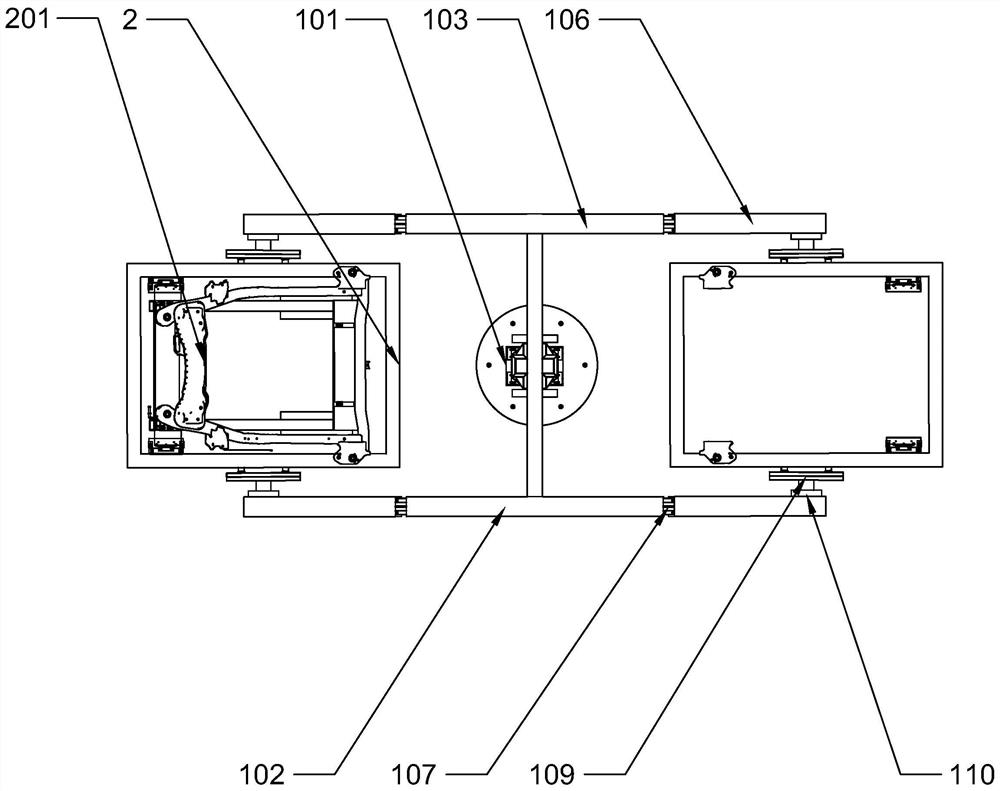

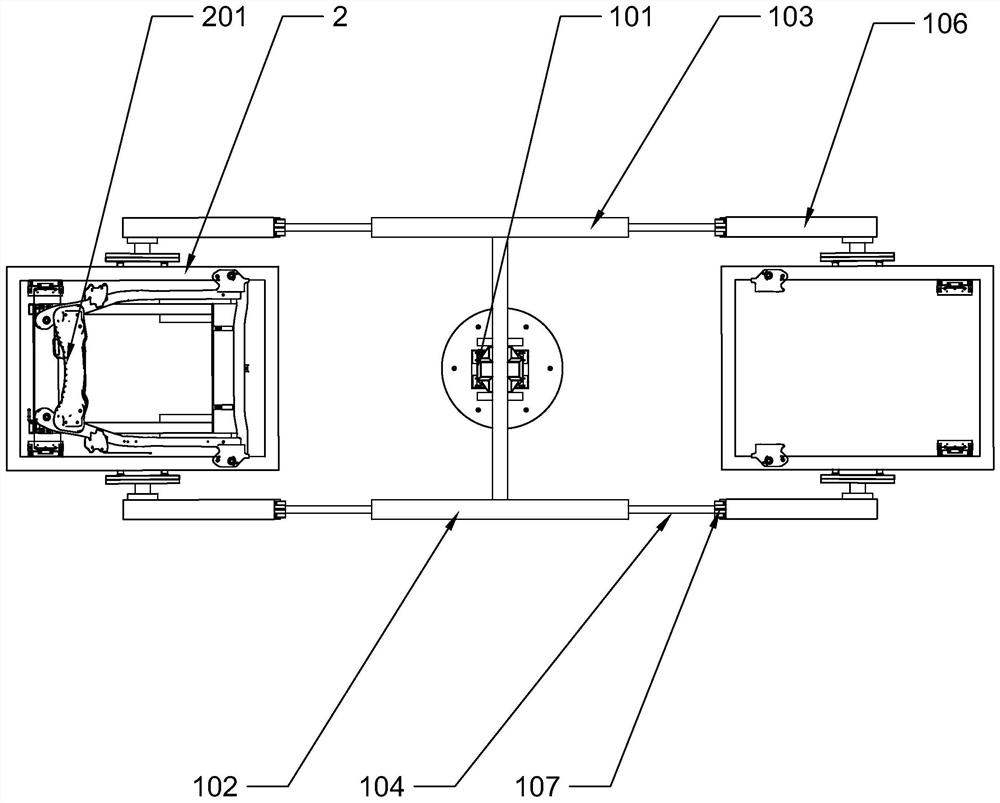

[0028] Such as figure 2 , image 3 with Figure 4 As shown, the slewing mechanism 1 includes a slewing seat 101 and a support frame. The bottom of the revolving base 101 is provided with a motor, and the revolving base 101 is driven by the motor to realize horizontal rotation. The middle parts of the first support beam 102 and the second support beam 103 are fixedly connected to the swivel base 101, and the first support beam 102 and the second support beam 103 are symmetrical to the center of the swivel base 101, thereby forming an "H"-shaped support frame .

[0029]Lead screws 105 are vertically connected to mid...

Embodiment 2

[0036] The features of the multi-station robot production line in this embodiment are basically the same as those in Embodiment 1, except that the repair welding workbench is further provided with a main fixture seat 502 , an auxiliary fixture seat 503 and a slide table 504 .

[0037] Such as Figure 5 As shown, the slide table 504 is sequentially divided into a first area 505 , a second area 506 and a third area 507 (areas marked with dotted lines). The slide rail 509 and the ball screw pair 508 are arranged through the first area 505 , the second area 506 and the third area 507 , and the slide rail 509 and the ball screw pair 508 are parallel to each other. The secondary fixture seat 503 has the same structure as the main fixture seat 502 , both are slidably connected to the slide rail 509 , and both are driven by the ball screw pair 508 to slide on the slide rail 509 . Wherein the main clamp seat 502 slides in the first area 505 and the second area 506 , and the auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com