A sound-absorbing foam plastic board

A foamed plastic board and foamed plastic technology, applied in the field of foamed plastic boards, can solve the problems of poor mid-low frequency sound absorption, reduced foam strength and the like, and achieve the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

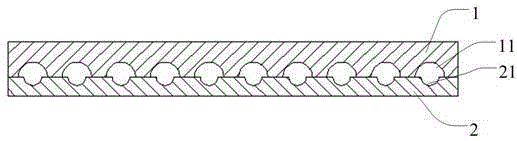

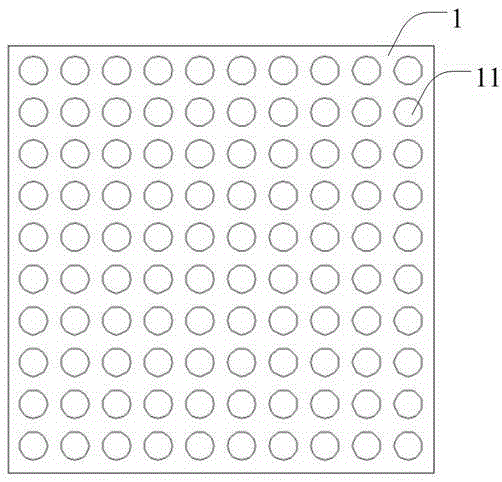

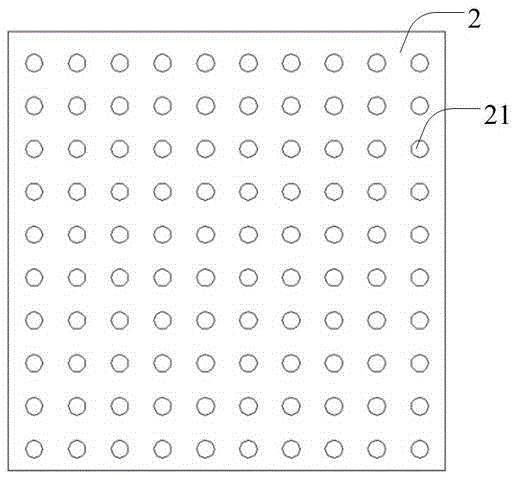

[0022] Both the first foamed plastics board and the second foamed plastics board are made of polystyrene foam, wherein the thickness of the first foamed plastics board is 6mm, and the thickness of the second foamed plastics board is 4mm; in the first foamed plastics board wherein The diameter of the hemispherical grooves on one side is 4mm, and the hemispherical grooves are distributed in a square lattice with a horizontal spacing of 7mm; The spacing is a square lattice distribution of 7mm; the first foam plastic plate is provided with the side of the hemispherical groove and the second foam plastic plate is provided with the side of the hemispherical groove with an adhesive to bond together the first foam plastic plate and the second foam plastic plate The two foam plastic plates are integrated, and the hemispherical groove of the first foam plastic plate and the hemispherical groove of the second foam plastic plate correspond to each other up and down during bonding.

[0023...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com