Fingerprint cover plate module and manufacturing method thereof

A production method and cover technology, which is applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of restricted fingerprint cover module size, poor user fingerprint recognition experience, and poor matching of mobile phones, etc., to achieve richness Color selection space, accurate fingerprint recognition operation, and improved matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

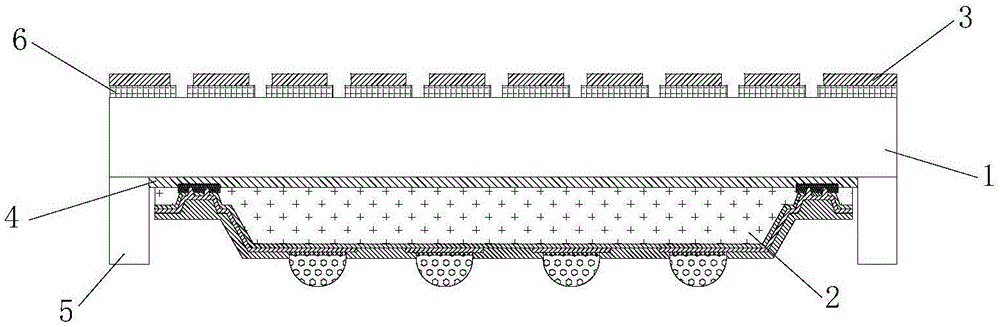

[0035] This embodiment provides a preferred fingerprint cover module to solve the problem that the existing fingerprint cover module has a single color and poor matching with the mobile phone panel. Such as figure 1 As shown, the fingerprint cover module includes a glass cover 1, one side of the glass cover 1 is provided with a metal grating layer 6 and a non-metallic grating layer 3 in sequence, and the other side is provided with a protection ring 5, and the inside of the protection ring 5 is uniformly coated There is a transparent glue layer 4 on which a fingerprint chip 2 is pasted. Here, the opaque metal grating layer 6 is uniformly coated on the glass cover 1 by sputtering, and the opaque non-metallic grating layer 3 is coated on the metal grating layer 6 by surface spin coating. Both the metal grating layer 6 and the non-metal grating layer 3 are etched with small grating holes by photolithography process, which are used to realize the identification function of the fi...

Embodiment 2

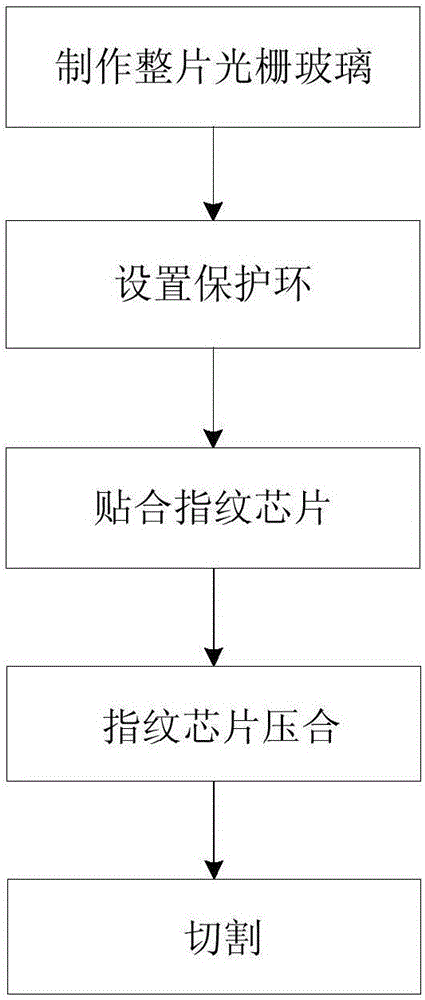

[0039] Such as figure 2 As shown, this embodiment proposes a preferred manufacturing method of the fingerprint cover module, the method includes the following steps:

[0040] A. Making the whole piece of grating glass: prepare the whole piece of glass cover plate, and evenly coat one side of the whole piece of glass cover plate with an opaque non-metallic layer, and then use photolithography to engrave the non-metallic layer in the light-transmitting area etched away to make a grating layer on the entire glass cover;

[0041] Preferably, the grating layer in this embodiment further includes a metal grating layer disposed between the non-metallic grating layer and the glass cover, so this step specifically includes the following three sub-steps:

[0042] A1. Prepare the entire glass cover, and sputter or evaporate a layer of opaque metal layer on the entire glass cover;

[0043] A2. Spin coating or spraying a layer of opaque non-metallic layer on the surface of the metal lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com