Color paste compatible inorganic building coating material and preparation method thereof

A kind of architectural coating and compatible technology, applied in the direction of coating, etc., can solve the problems of insufficient color brightness of inorganic pigment paste, floating color, and few types of inorganic pigments, etc., to achieve a wide range of color choices, convenient selection and replacement, Excellent effect of authenticity of hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a color paste-compatible inorganic architectural coating and a preparation method thereof;

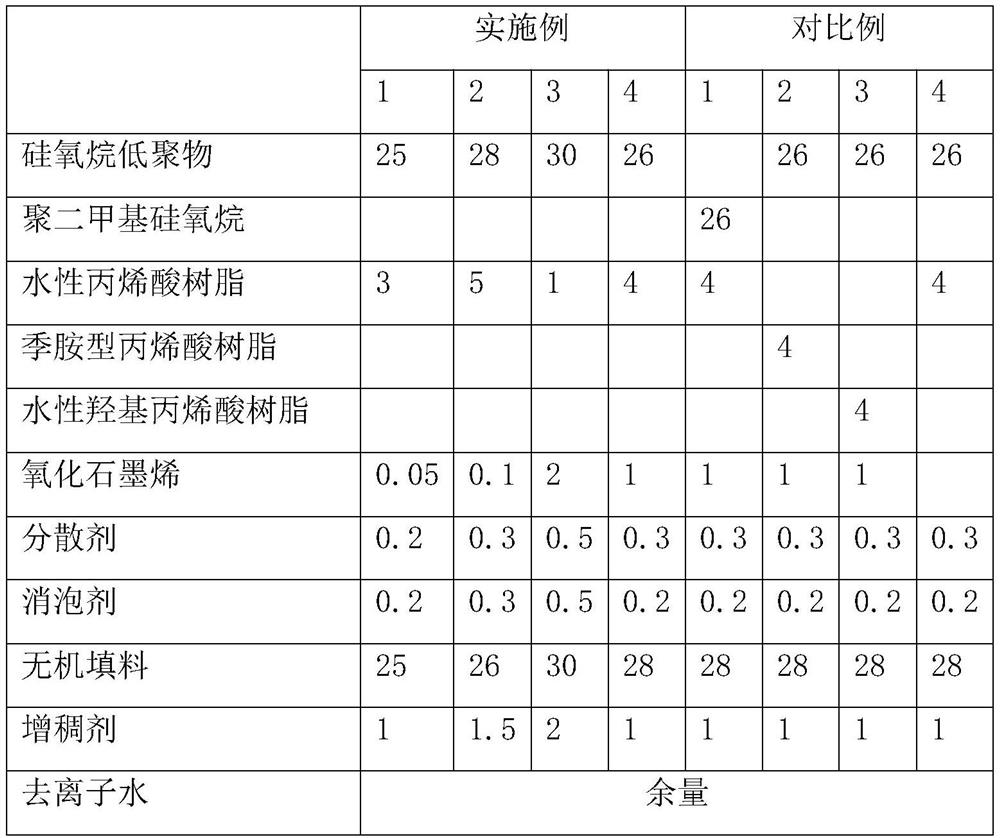

[0040] Color paste-compatible inorganic architectural coatings are divided into two components, A and B. In terms of 100%, the formula is as follows:

[0041] A component:

[0042] Silicone oligomer: 25-30%

[0043] Water-based acrylic resin: 1-5%

[0044] Graphene oxide: 0.05-2%

[0045] Dispersant: 0.2-0.5%

[0046] Defoamer: 0.2-0.5%

[0047] Inorganic filler: 25-30%

[0048] Thickener: 1-2%

[0049] Deionized water: balance

[0050] B component: universal color paste: 15-25%.

[0051] in:

[0052] Siloxane oligomer: the main film-forming substance, with a pH value of 3-4 and a degree of polymerization of 20-50. If the degree of polymerization is too small, the coating will have low hardness and poor wear resistance after curing; After the film is formed, the coating has high hardness and is easy to crack. In order to prevent the coating from...

Embodiment 1

[0068] This embodiment relates to a color paste-compatible inorganic architectural coating, the composition and ratio of which are shown in Table 1. The preparation method is as follows:

[0069] (1) Graphene oxide dispersion: Graphene oxide was mixed with a small amount of deionized water, and put into ultrasonic dispersion for 60 minutes to obtain a graphene oxide dispersion;

[0070] (2) Preparation of filler slurry: mix siloxane oligomer, dispersant, inorganic filler, deionized water, 60% defoamer, and graphene oxide dispersion evenly, grind on a grinder until the fineness is less than 20 μm, and use 300 mesh filter cloths are filtered to obtain filler slurry;

[0071] (3) The thickener is mixed with a 10% transparent solution for use;

[0072] (4) Mix the filler slurry, thickener, acidic acrylic resin, and 40% defoamer evenly, and the pH value is ≤5.5;

[0073] (5) Add the universal color paste to the coating obtained in step (4), and mix evenly to obtain a colored ino...

Embodiment 2

[0076] This embodiment relates to a color paste-compatible inorganic architectural coating, the composition and ratio of which are shown in Table 1. The preparation method is as follows:

[0077] (1) Graphene oxide dispersion: Graphene oxide was mixed with a small amount of deionized water, put into ultrasonic dispersion for 45 minutes, and obtained graphene oxide dispersion liquid;

[0078] (2) Preparation of filler slurry: mix siloxane oligomer, dispersant, inorganic filler, deionized water, 70% defoamer, and graphene oxide dispersion evenly, grind on a grinder until the fineness is less than 20 μm, and use 300 mesh filter cloths are filtered to obtain filler slurry;

[0079] (3) thickener is mixed with 8% transparent solution, stand-by;

[0080] (4) Mix the filler slurry, thickener, acidic acrylic resin, and 30% defoamer evenly, and the pH value is ≤5.5;

[0081] (5) Add the universal color paste to the coating obtained in step (4), and mix evenly to obtain a colored ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com