Method for producing pre-spinning dyed coarse denier polypropylene ATY fiber used outdoors

A pre-spinning coloring and production method technology, which is applied in the field of fiber manufacturing, can solve the problems of appearance color error, production difficulty, dyeing difficulty, etc., and achieve the effect of small color difference, low production difficulty, and rich and colorful color selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

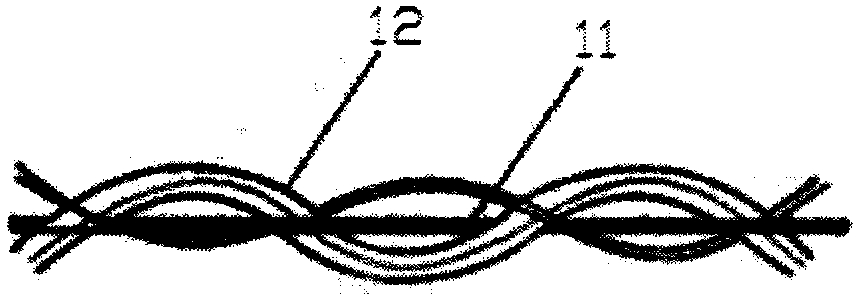

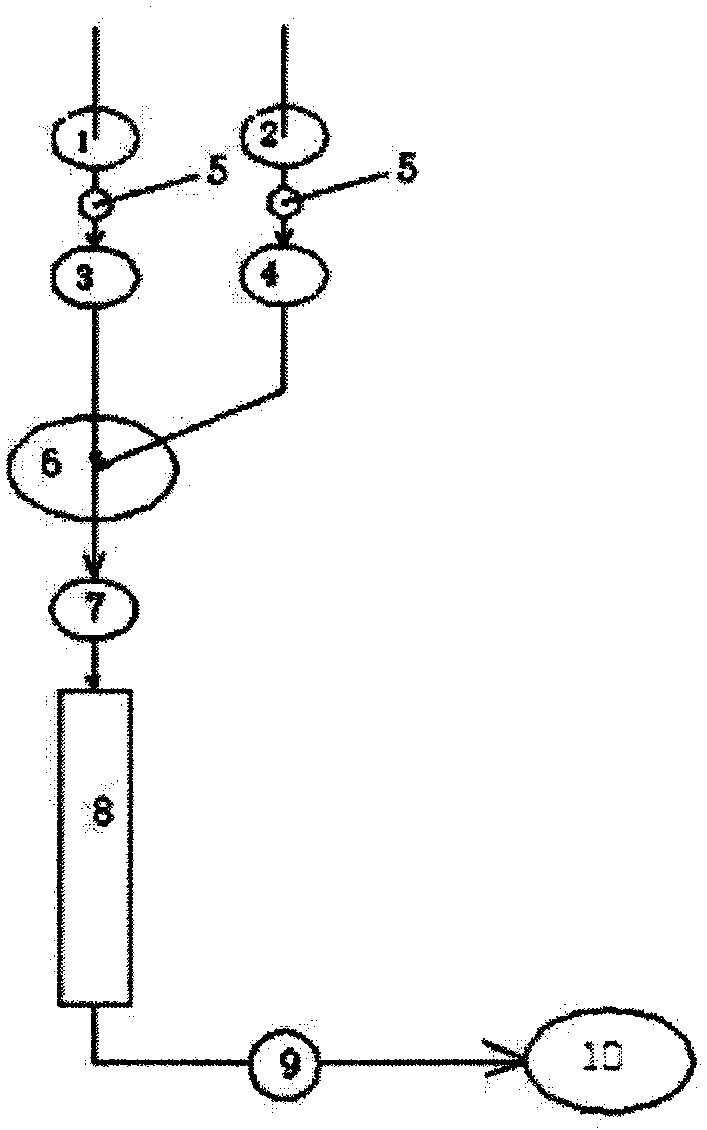

[0018] Embodiment 1: refer to figure 1 As shown, a kind of pre-spinning colored thick denier polypropylene ATY fiber for outdoor use is made of core silk and leather silk 12 on the periphery of core silk 11, and the materials of core silk 11 and leather silk 12 are all pre-spinning colored thick denier polypropylene (polypropylene ) FDY fiber, the mass percentage of skin silk and core silk is 1:2, refer to figure 2 , the preparation method is as follows: using pre-spun dyed thick denier polypropylene (polypropylene) FDY fiber with a specification of 200dt / 48f as the processing raw material, using a conventional air texturing machine, using the first roller 1 and the second roller 2 to feed the filaments, and passing through Hot-selling 5 heat-stretching treatment, and then stretched by the third roller 3 and the fourth roller 4, the core yarn 11 (colored coarse denier polypropylene FDY fiber before spinning) is fed through the first roller 1 to the hot-selling 5 hot-stretchin...

Embodiment 2

[0020] Embodiment 2: Embodiment 1: refer to figure 1 As shown, a kind of pre-spinning colored thick denier polypropylene ATY fiber for outdoor use is made of core silk and leather silk 12 on the periphery of core silk 11, and the materials of core silk 11 and leather silk 12 are all pre-spinning colored thick denier polypropylene (polypropylene ) FDY fiber, the mass percentage of leather silk and core silk is 2:1, refer to figure 2 , and its preparation method is: use pre-spun dyed coarse denier polypropylene (polypropylene) FDY fiber with a specification of 200-300dt / 48-72f as the processing raw material, use a conventional air texturing machine, and use the first roller 1 and the second roller 2 to feed After hot-selling 5 heat-stretching treatment, and then stretched by the third roller 3 and the fourth roller 4, the core yarn 11 (colored coarse denier polypropylene FDY fiber before spinning) is fed into the hot-selling yarn through the first roller 1 5. After heat stretc...

Embodiment 3

[0022] Embodiment 3: Embodiment 1: with reference to figure 1 Shown, a kind of pre-spinning coloring coarse denier polypropylene ATY fiber for outdoors is made of core silk, the skin silk 12 of core silk 11 periphery, and the material of core silk 11, leather silk 12 is the pre-spinning coloring coarse denier polypropylene fiber (polypropylene ) FDY fiber, the mass percentage of skin silk and core silk is 1:1, refer to figure 2, and its preparation method is: use pre-spun dyed coarse denier polypropylene (polypropylene) FDY fiber with a specification of 200-300dt / 48-72f as the processing raw material, use a conventional air texturing machine, and use the first roller 1 and the second roller 2 to feed After hot-selling 5 heat-stretching treatment, and then stretched by the third roller 3 and the fourth roller 4, the core yarn 11 (colored coarse denier polypropylene FDY fiber before spinning) is fed into the hot-selling yarn through the first roller 1 5. After heat stretching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com