Communication lumped parameter circulator based on MEMS technology and manufacturing method thereof

A technology of lumped parameters and production methods, applied in waveguide devices, electrical components, circuits, etc., can solve problems that cannot meet the development of microstrip circulators, improve production efficiency and product consistency, reduce process difficulty, prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

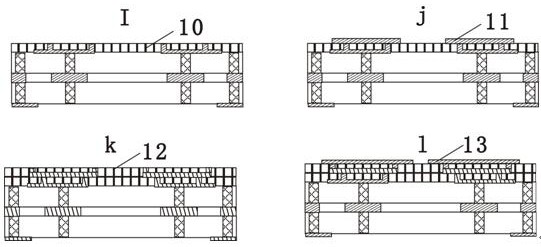

[0049] A lumped parameter circulator for communication based on MEMS technology, see Figure 7 , its main structure includes a silicon master substrate 1, a silicon sub-substrate 2 is arranged below the silicon master substrate 1, and two layers of polyimide films are arranged above the silicon master substrate 1, respectively A layer of polyimide 10 and a second layer of polyimide 12; circuit patterns are made on the upper surface and the lower surface of the silicon master substrate 1 and the silicon sub-substrate 2, and the silicon master substrate 1 It is interconnected with the silicon sub-substrate 2 through metal vias and bonding; the polyimide film on each layer is also made with a circuit pattern, and is interconnected with the circuit of the lower layer through the metallized vias on the polyimide film;

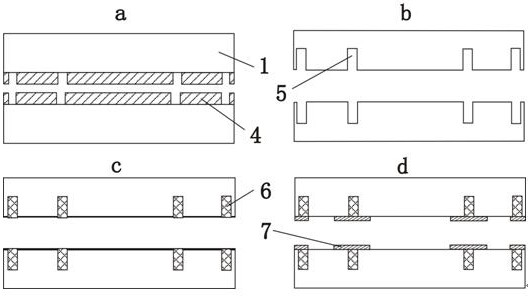

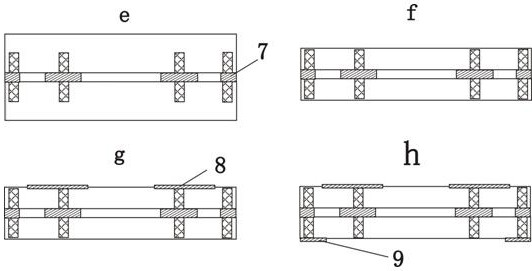

[0050] The manufacture method of above-mentioned circulator, see Figure 1-4 , including the following steps:

[0051] (1) Use a double-sided polished high-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com