Conductive oxide transition layer and phase-changing memory unit with same

A conductive oxide and phase-change memory technology, applied in static memory, digital memory information, electrical components, etc., can solve problems affecting voltage/current matching, composition segregation, operating voltage/current increase, etc., to ensure consistency, Effects of improving operational reliability, improving reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

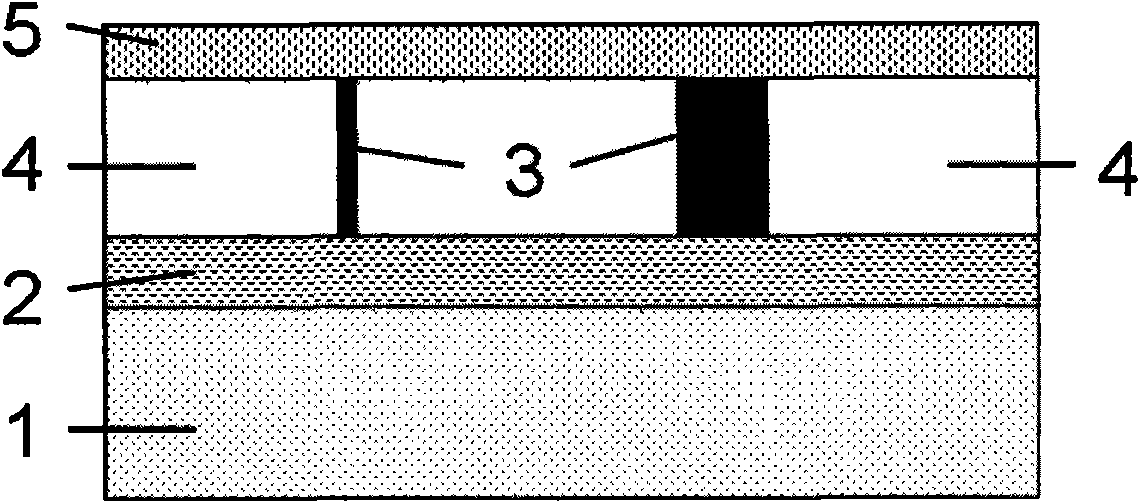

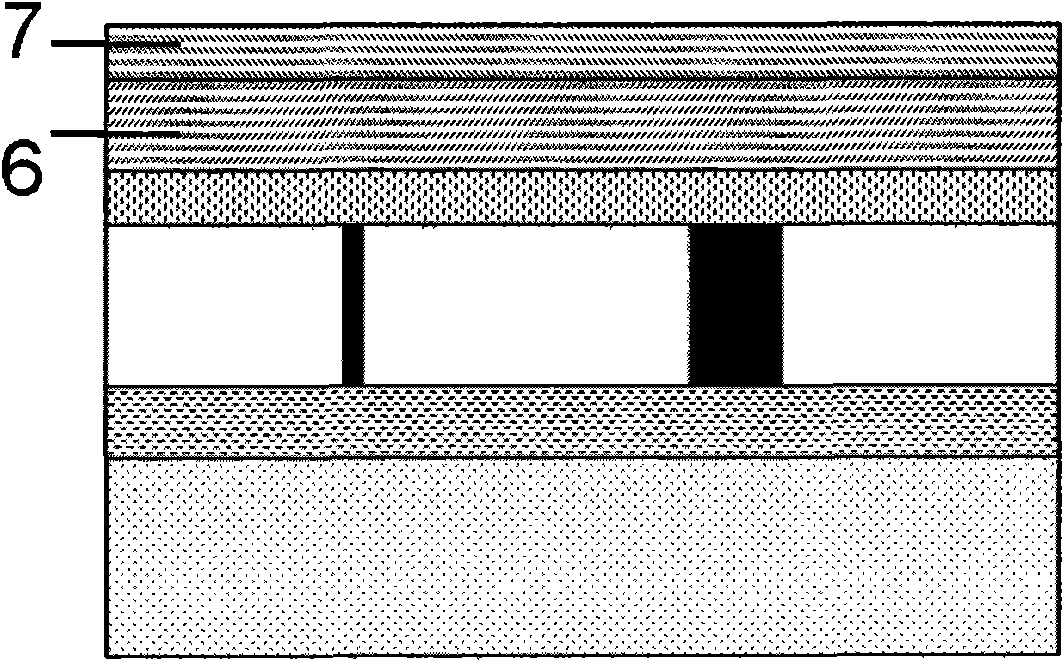

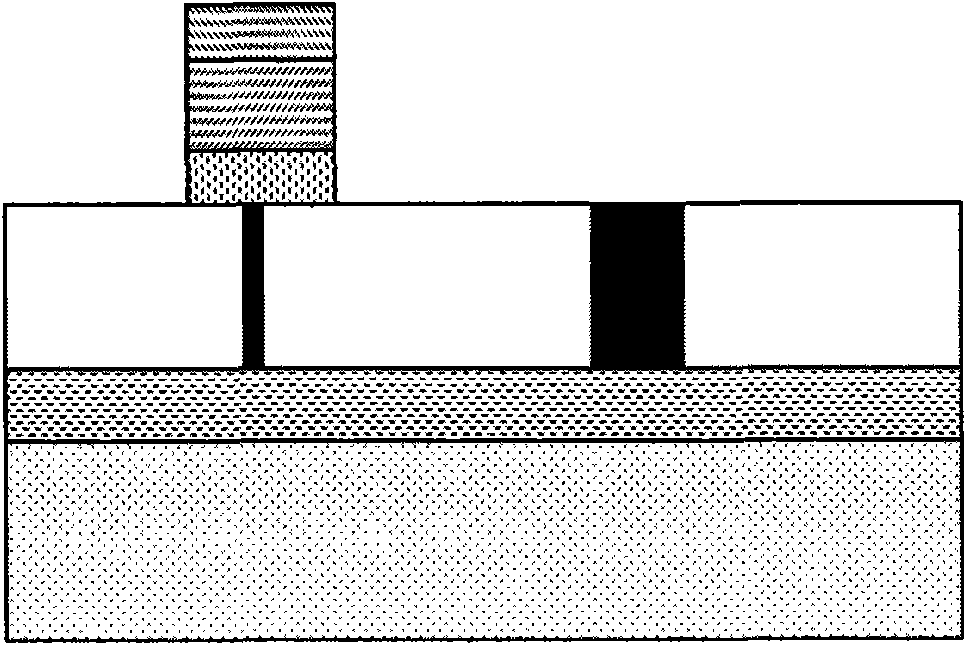

[0046] A phase-change memory unit includes a bottom electrode and a chalcogen compound thin film layer, and also includes a conductive oxide transition layer between the bottom electrode and the chalcogen compound thin film layer. Wherein, the melting point of the conductive oxide transition layer material is 600°C-2500°C; the thermal conductivity is 0.1-120W / mK.

[0047] The material of the conductive oxide transition layer should have high thermal stability, at the melting point of the chalcogenide compound (such as Ge 2 Sb 2 Te 5 It still maintains its thermal stability at a temperature above the melting point of ~600°C, that is, the transition layer material is required to have a melting point greater than that of the chalcogenide compound. And in the temperature range between room temperature and the melting point of the chalcogenide compound, the basic properties of the film of this material, that is, the physical properties (resistivity, film thickness, film roughness...

Embodiment 2

[0063] Adopt the same technical scheme as Example 1, the difference is that the material of the conductive oxide transition layer prepared in step (1) is changed to LaSrCoO 3 , LaSrMnO 3 , SrRuO 3 , CaRuO 3 and other materials, or Nb-doped SrTiO 3 , can also achieve the same technical effect. The melting point of these conductive oxide materials is 600°C-2500°C; the thermal conductivity is 0.1-120W / mK. Wherein, these materials and their preparation methods are well-known techniques of those skilled in the art, and the innovation of the present invention is not these materials themselves, so details will not be repeated here.

Embodiment 3

[0065] Adopt the same technical scheme as embodiment one, the difference is that the material of the chalcogenide film layer described in step (2) is replaced by Sb 2 Te 3 、 Ge 1 Sb 4 Te 7 or Ge 1 Sb 2 Te 4 One of them, or a compound modified by doping one or two elements of N, O, Si, Sn, Ag or In.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com