Manufacturing method of N type/P type monocrystalline silicon crystal ingot

A manufacturing method and technology of single crystal silicon, which are applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of low utilization rate of doping gas, difficult doping elements, poor operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

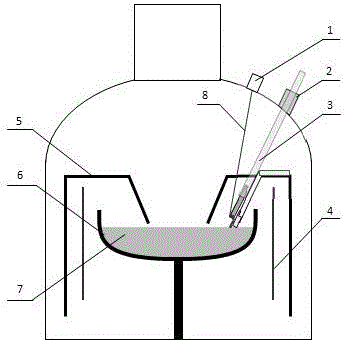

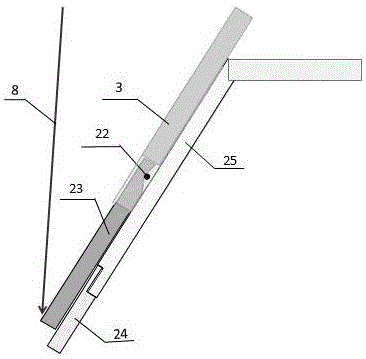

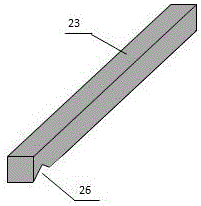

Image

Examples

Embodiment 1

[0038] An 8-inch N-type monocrystalline silicon rod in the direction was grown by the Czochralski method. Add 120Kg of polysilicon raw material and main dopant element phosphorus into the quartz crucible, the initial concentration of phosphorus is 8E13atoms / cm 3 . Under the protection of inert gas (usually argon), turn on the heater and gradually increase the temperature to above 1420°C to completely melt the raw materials.

[0039] According to the conventional Czochralski method single crystal silicon growth process such as seeding, necking, shouldering, and shouldering, etc. enters the equal-diameter growth process. From a P-type monocrystalline silicon rod with a diameter of 300 mm and a resistivity of 0.3 Ω·cm, a single crystal silicon strip of 20 mm×20 mm×200 mm is cut along the diameter direction. Since the doping element boron has a concentration deviation along the crystal growth direction, but is uniformly distributed in the diameter direction, this sampling metho...

Embodiment 2

[0045] 8-inch P-type monocrystalline silicon rods in the direction were grown by the Czochralski method. Add 120kg of polysilicon raw material and boron into the quartz crucible, the initial concentration of boron is 1.78E14 atoms / cm 3 . Under the protection of inert gas (usually argon), turn on the heater and gradually increase the temperature to above 1420°C to completely melt the raw materials.

[0046] According to the conventional crystal growth parameters, seeding, shouldering, shoulder turning, and entering the equal-diameter stage are carried out. Cut out a 20mm×20mm×250mm monocrystalline silicon strip along the diameter direction from a phosphorus-doped monocrystalline silicon rod with a diameter of 300mm and a resistivity of 20Ω·cm, and fix it on a support as a source of secondary doping elements. When the solidification rate is 0.4, that is, when the crystal weight is 48kg, turn on the laser array, set the power to 50W, and melt a 0.46cm single crystal silicon st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com