CCCW-mixing carbon fiber graphite smart concrete and application thereof

A CCCW and concrete technology, applied in the field of concrete, can solve the problems of unstable electrical conductivity and sensitive properties, insufficient dispersion process, etc., and achieve the effects of reducing polarization effects, improving microstructure, low resistivity and pressure-sensitive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

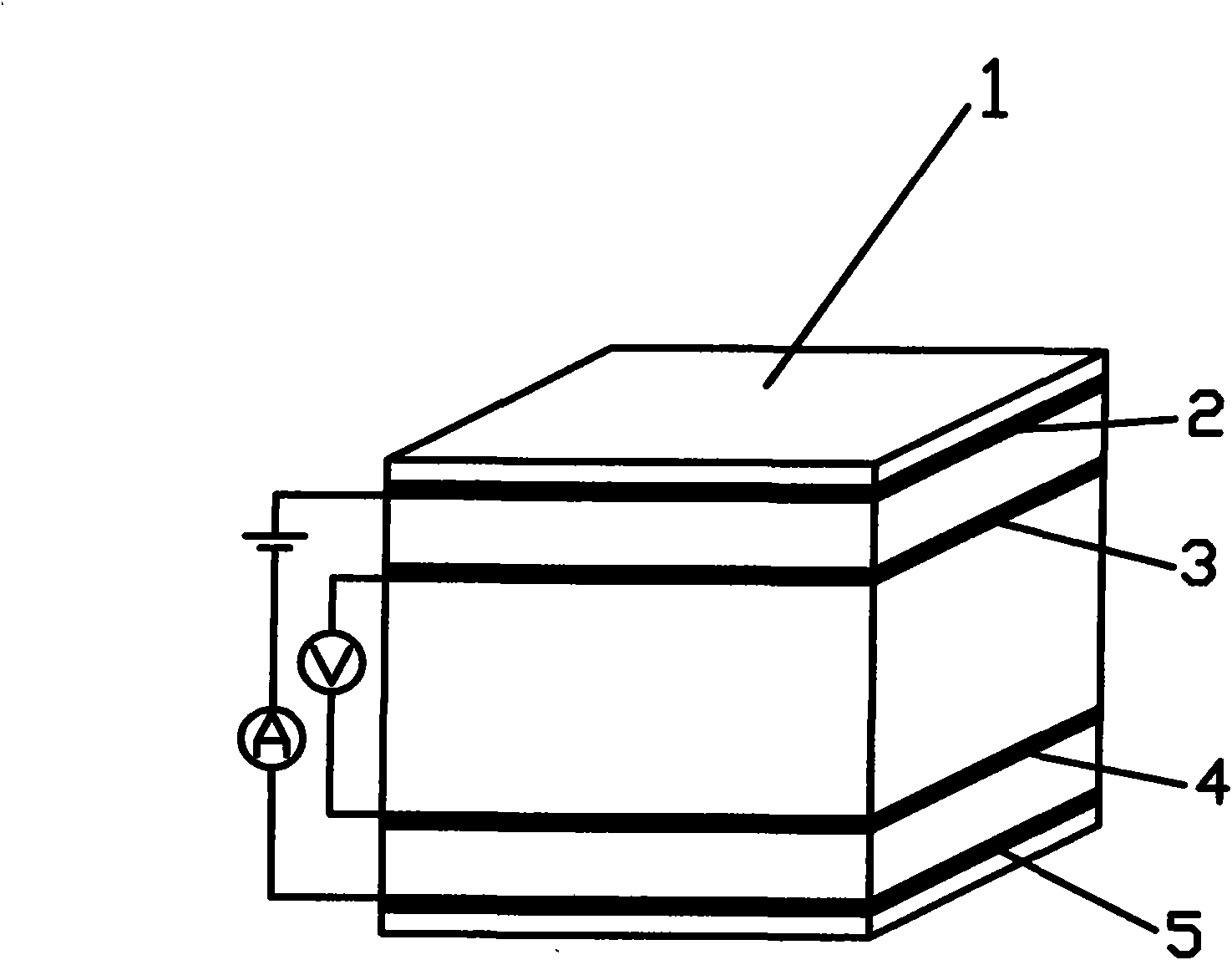

[0030] Embodiment 1: prepare the carbon fiber graphite cement-based composite material sensing element that mixes CCCW inside, its size is 40mm * 40mm * 40mm (see figure 1). Use 42.5 ordinary Portland cement. Quartz sand for ordinary casting, with a particle size of 0.154mm to 0.315mm. The ratio of raw materials and the resistivity of the corresponding test blocks after 28 days of curing are shown in Table 1. The effect of adding CCCW on the compressive strength of the material is shown in Table 2. The ratio of CCCW material, carbon fiber, graphite, carbon fiber dispersant and defoamer is represented by the percentage of the total mass of cement and sand.

[0031] It is known from Table 1 that under the condition of a certain amount of carbon fiber added, as the amount of graphite increases, the conductivity becomes better. When the dosage is about 10%, increasing the graphite content has little effect on the resistivity of the material. The values of carbon fiber, grap...

Embodiment 2

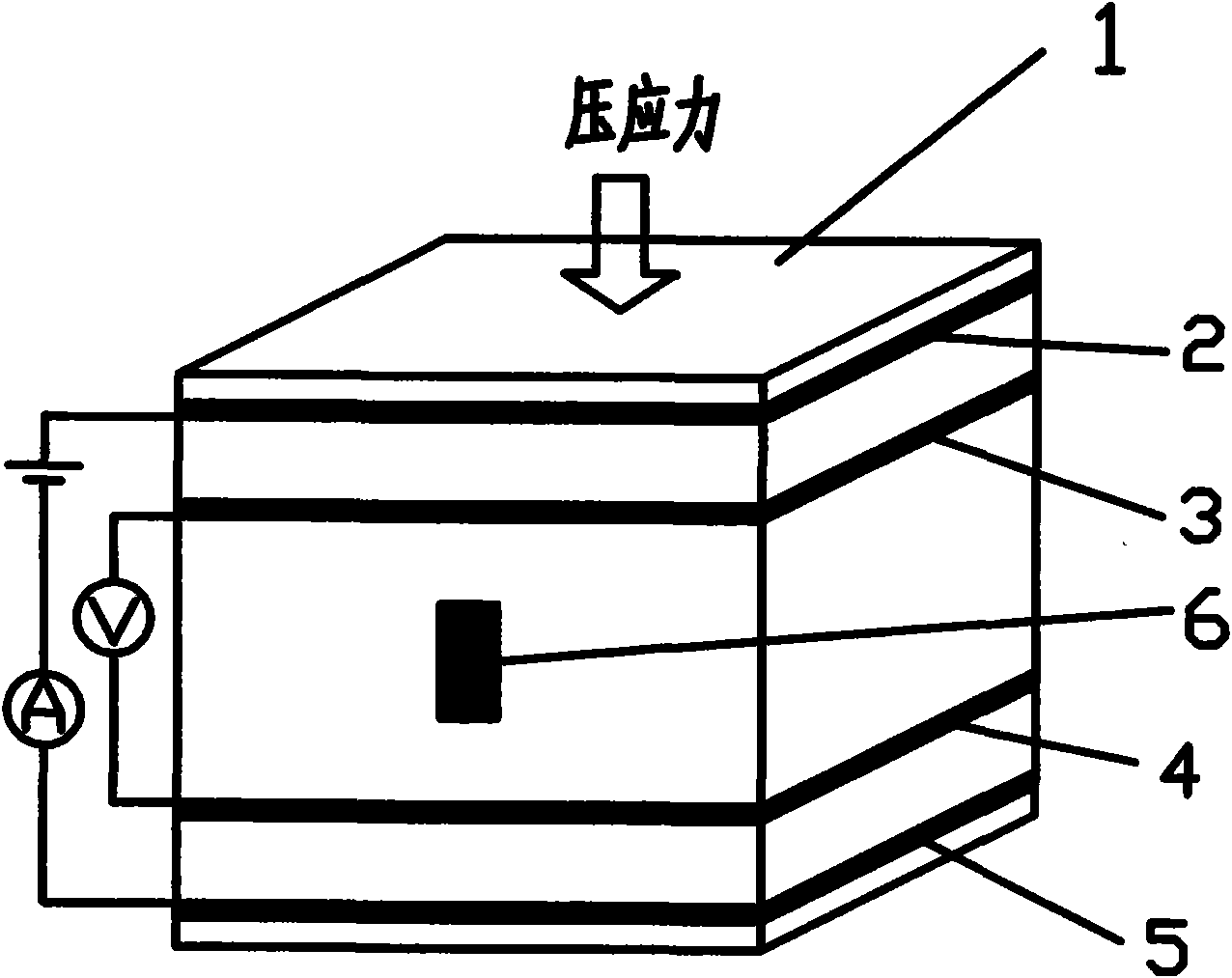

[0033] Embodiment 2: The sensor element 40mm * 40mm * 40mm prepared by the above process, and adopt figure 2 The test system shown performs pressure sensitivity testing of materials. Put the sample on the INSTRON 5882 universal material testing machine to form a pressure-sensitive test system to measure the resistance change of the graphite cement mortar test block under cyclic loading. Simultaneously, the YE2539 high-speed static strain gauge is used to record the strain value of the sample during loading. The loading method is triangular wave cyclic loading, and the loading and unloading rate is controlled as one cycle per minute. The maximum compressive stress is 6.25MPa, and the piezoresistive characteristics of the sample are studied for 5 cycles, and the strain sensitivity coefficient is analyzed. Under cyclic loading, there is a certain correspondence between the resistivity and stress of the sensing element of samples with different graphite content. When the graph...

Embodiment 3

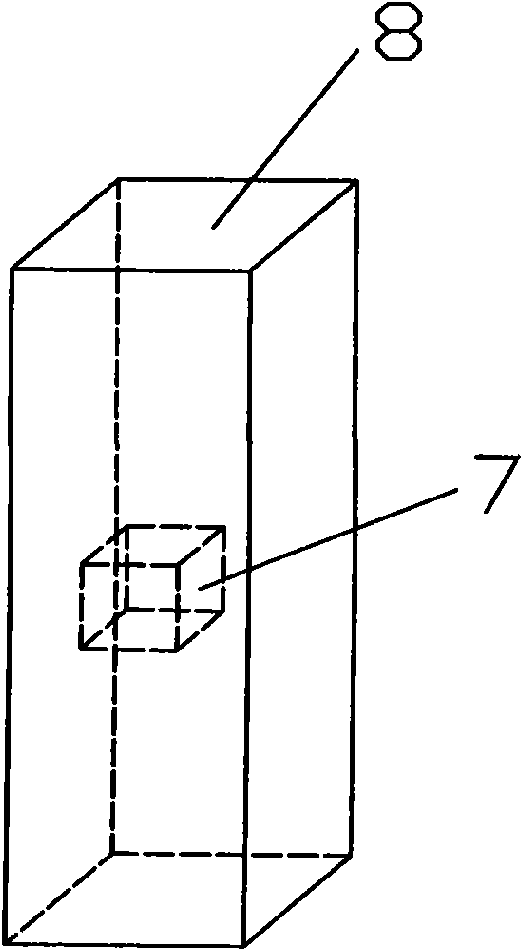

[0034] Embodiment 3: will figure 1 The sensing element shown is 40mm×40mm×40mm (2% CCCW, 0.5% carbon fiber, 10% graphite content) encapsulated with epoxy resin, and embedded in the center of a 100mm×100mm×300mm short column. The column is prepared according to C30 concrete, such as image 3 shown. A cyclic pressure load is applied to the column, the loading system and the measured resistivity change of the sensing element are as follows: Figure 4 As shown, there is a certain corresponding relationship between resistivity and loading stress, and the repeatability is good. When the pressure is monotonously loaded on the column, the relationship between resistivity and compressive stress is as follows: Figure 5 shown. The sensing element can sense the force condition of the structure very well, Figure 5 The three stages AB, BC and CD correspond to the elastic range, plastic range and failure range of the carbon fiber graphite stress-strain sensor, respectively. Therefore,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com