Preparation of carbon / carbon composite material heating element for polysilicon furnace

A carbon composite material and heating element technology, applied in heating element materials and other directions, can solve the problems of difficult process control of ultra-high-purity graphite materials, pollution of polysilicon products, high price, etc., to achieve continuous stability, inhibit penetration and densification, and improve The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

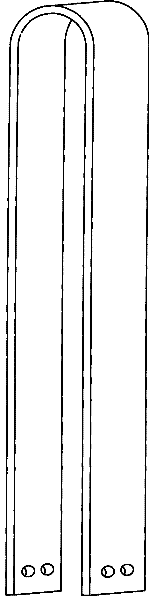

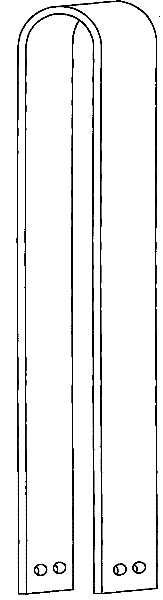

[0029] (1) Weave the polyacrylonitrile-based carbon fiber needle-punched integral felt into a U-shaped carbon fiber blank according to the design requirements, and place the U-shaped carbon fiber blank on the graphite tooling that has undergone high-temperature purification to maintain its shape;

[0030] (2) Deposit the U-shaped carbon fiber green body and tooling together after high-temperature purification and pretreatment, and the heat treatment temperature is 1600°C;

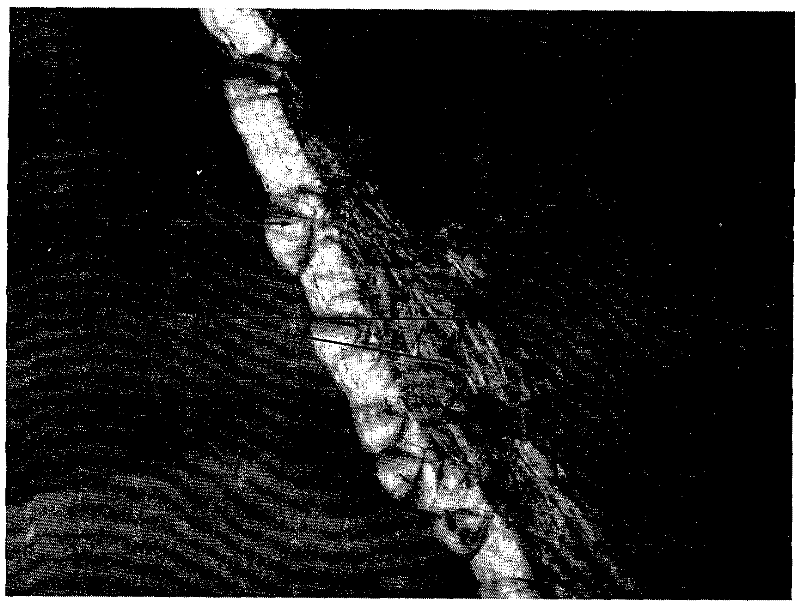

[0031] (3), put the U-shaped carbon fiber green body and the tooling into the chemical vapor infiltration furnace together, and use high-purity N 2 For carrier gas and dilution gas, purified C 3 h 6 It is carbon source gas, which is mixed and passed into a high-temperature infiltration furnace for cracking and densification to prepare a carbon / carbon composite green body. The densification process is: C 3 h 6 : 12L / mim, N 2 : 20L / min, densification temperature: 900℃, time 180h, furnace pressure 2.5kPa; ...

Embodiment 2

[0036] (1) Weave the polyacrylonitrile-based carbon fiber needle-punched integral felt into a U-shaped carbon fiber blank according to the design requirements, and place the U-shaped carbon fiber blank on the graphite tooling that has undergone high-temperature purification to maintain its shape;

[0037] (2) Deposit the U-shaped carbon fiber green body and tooling together after high-temperature purification and pretreatment, and the heat treatment temperature is 1800°C;

[0038] (3), put the U-shaped carbon fiber green body and the tooling into the chemical vapor infiltration furnace together, and use high-purity N 2 For carrier gas and dilution gas, purified C 3 h 6 It is carbon source gas, which is mixed and passed into a high-temperature infiltration furnace for cracking and densification to prepare a carbon / carbon composite green body. The densification process is: C 3 h 6 : 10L / mim, N 2 : 15L / min. Densification temperature: 980°C, time 240h, furnace pressure 1.5kPa...

Embodiment 3

[0043] (1) Weave the polyacrylonitrile-based carbon fiber needle-punched integral felt into a U-shaped carbon fiber blank according to the design requirements, and place the U-shaped carbon fiber blank on the graphite tooling that has undergone high-temperature purification to maintain its shape;

[0044] (2) Deposit the U-shaped carbon fiber green body and tooling together after high-temperature purification and pretreatment, and the heat treatment temperature is 2000°C;

[0045] (3), put the U-shaped carbon fiber green body and the tooling into the chemical vapor infiltration furnace together, and use high-purity N 2 For carrier gas and dilution gas, purified C 3 h 6 It is carbon source gas, which is mixed and passed into a high-temperature infiltration furnace for cracking and densification to prepare a carbon / carbon composite green body. The densification process is: C 3 h 6 : 15L / mim, N 2 : 20L / min, densification temperature: 950℃, time 150h, furnace pressure 2.0kPa; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com