Water-based anti-rust primer

An anti-rust primer, water-based technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the gap of water-based technology, cannot withstand high temperature baking, and is difficult to achieve high gloss and high vividness and other problems, to achieve the effect of a wide range of construction technology, excellent salt spray resistance, and loose construction environment temperature and humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

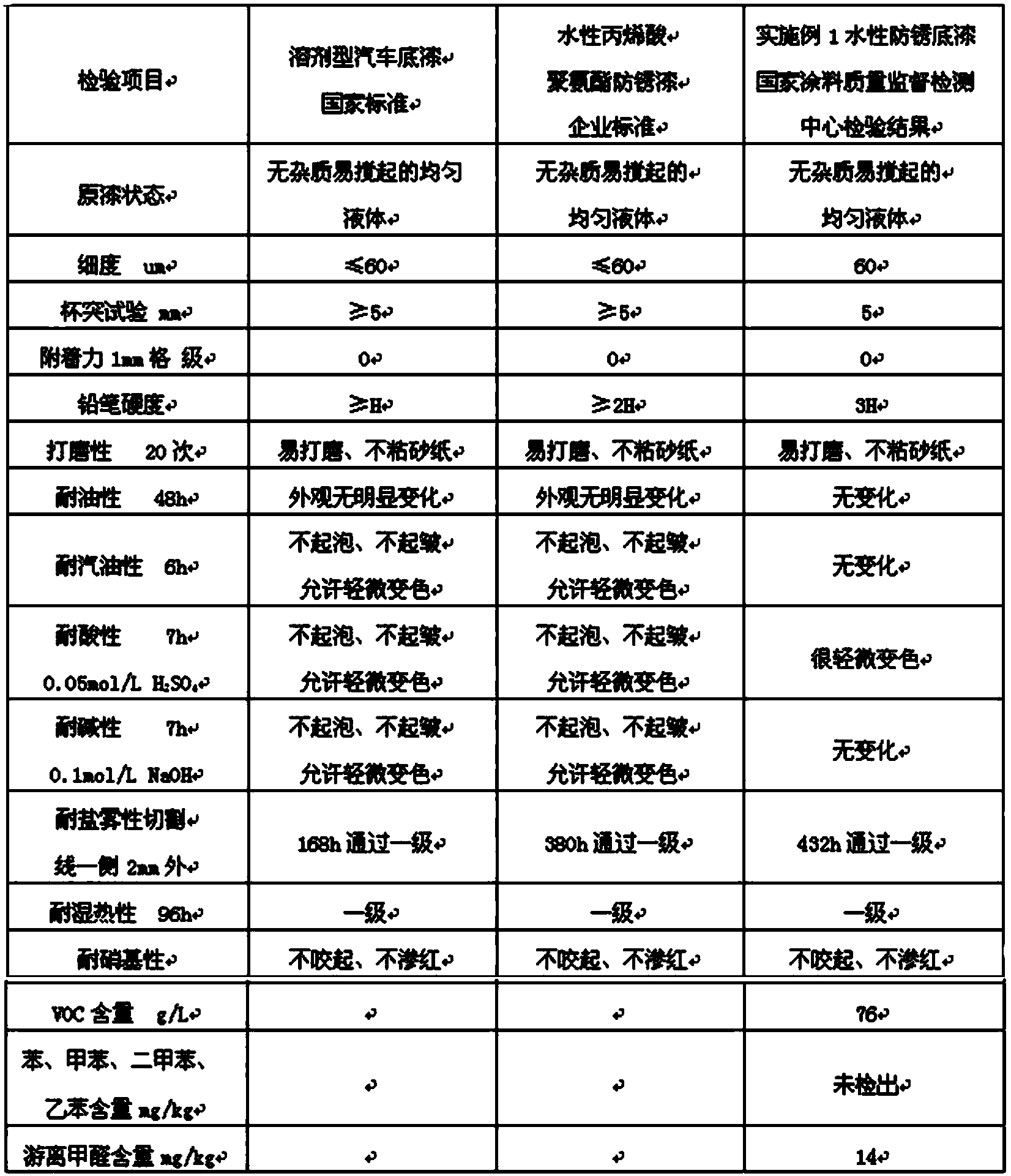

Embodiment 1

[0020] The water-based antirust primer for automobile painting provided by this embodiment is composed of A component and B component, wherein the composition of A component is shown in Table 1, and B component is Bayer VPLS2319, A component and B component The weight ratio of the components is 10:1.

[0021] The composition of the A component of table 1 embodiment 1

[0022] A composition The A component of embodiment 1 is composed weight percentage Water-Based Acrylic Emulsion Bayer XP2470 resin, Aberdinck AC31 resin 40.7 Antirust Pigment Elements 6597 iron red, zinc yellow 20 Extender pigment Superfine talcum powder, superfine barium sulfate 30 Defoamer BYK Byk011, Byk028 0.8 Dispersant BYK191 BYK 1.0 leveling agent BYK Byk381 0.3 Substrate wetting agent BYK Byk348 0.5 Rheology Additives Tegoza Corporation Hy 0.1 Anti-flash rust agent Wally Corporation ADD458 2 Deionized water Deioniz...

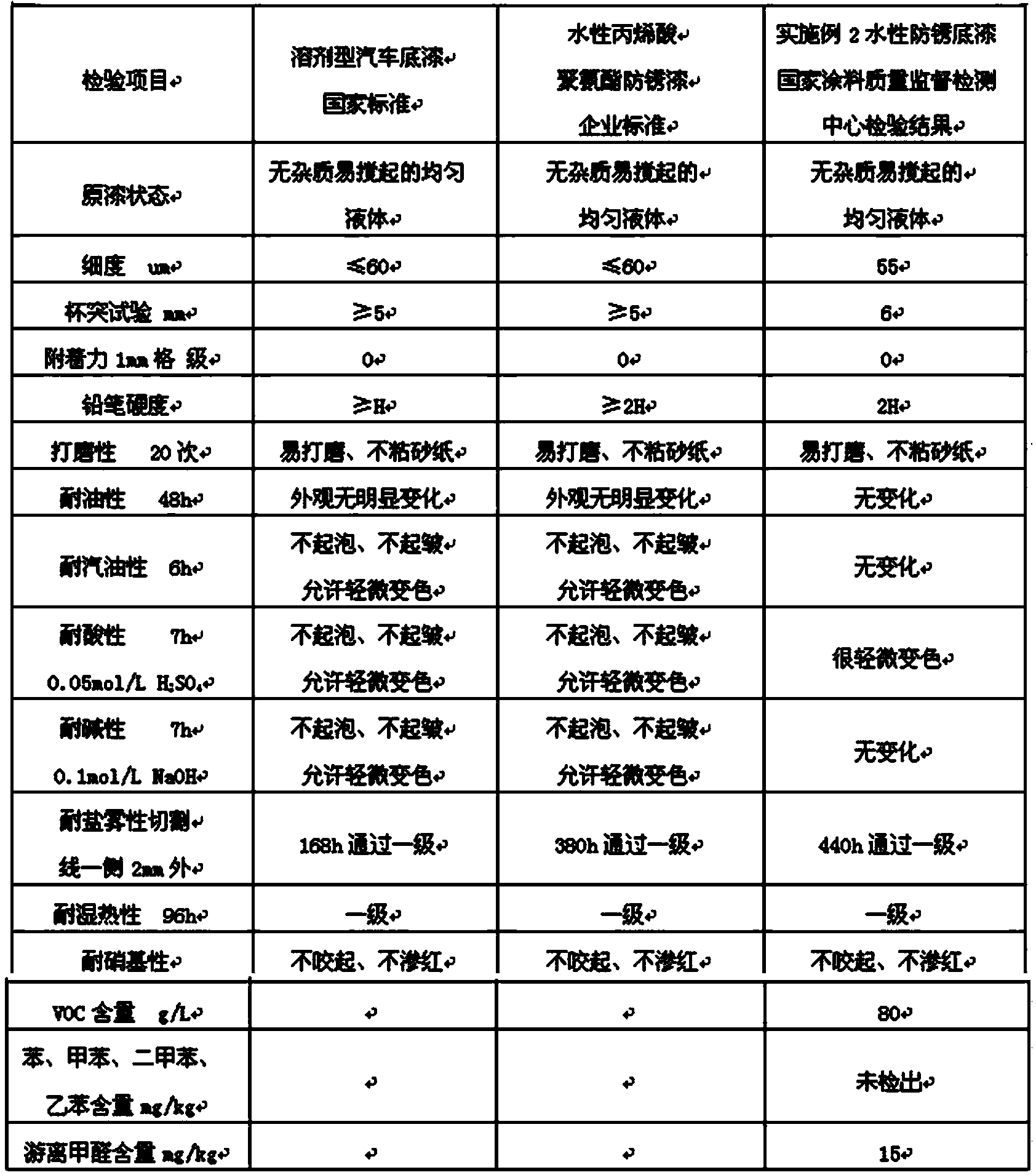

Embodiment 2

[0025] The water-based antirust primer for automobile painting provided by this embodiment is composed of component A and component B, wherein the composition of component A is shown in Table 2, and component B is a mixture of Bayer's VPLS2319 and Bayer's XP2565 , The weight ratio of component A and component B is 8:1.

[0026] The composition of the A component of table 2 embodiment 2

[0027] A composition The A component of embodiment 2 is composed weight percentage Water-Based Acrylic Emulsion Bayer XP2470 resin, DSM XK540 resin 44.5 Antirust Pigment Elements 6597 iron red, zinc yellow 20 Extender pigment Superfine talcum powder, superfine barium sulfate 29.8 Defoamer BYK Byk011, Byk028 0.8 Dispersant Tego Disper735w 1.0 leveling agent BYK Byk381 0.3 Substrate wetting agent BYK Byk348 0.5 Rheology Additives Tegoza Corporation Hy 0.1 Anti-flash rust agent Wally Corporation ADD458 0.5 De...

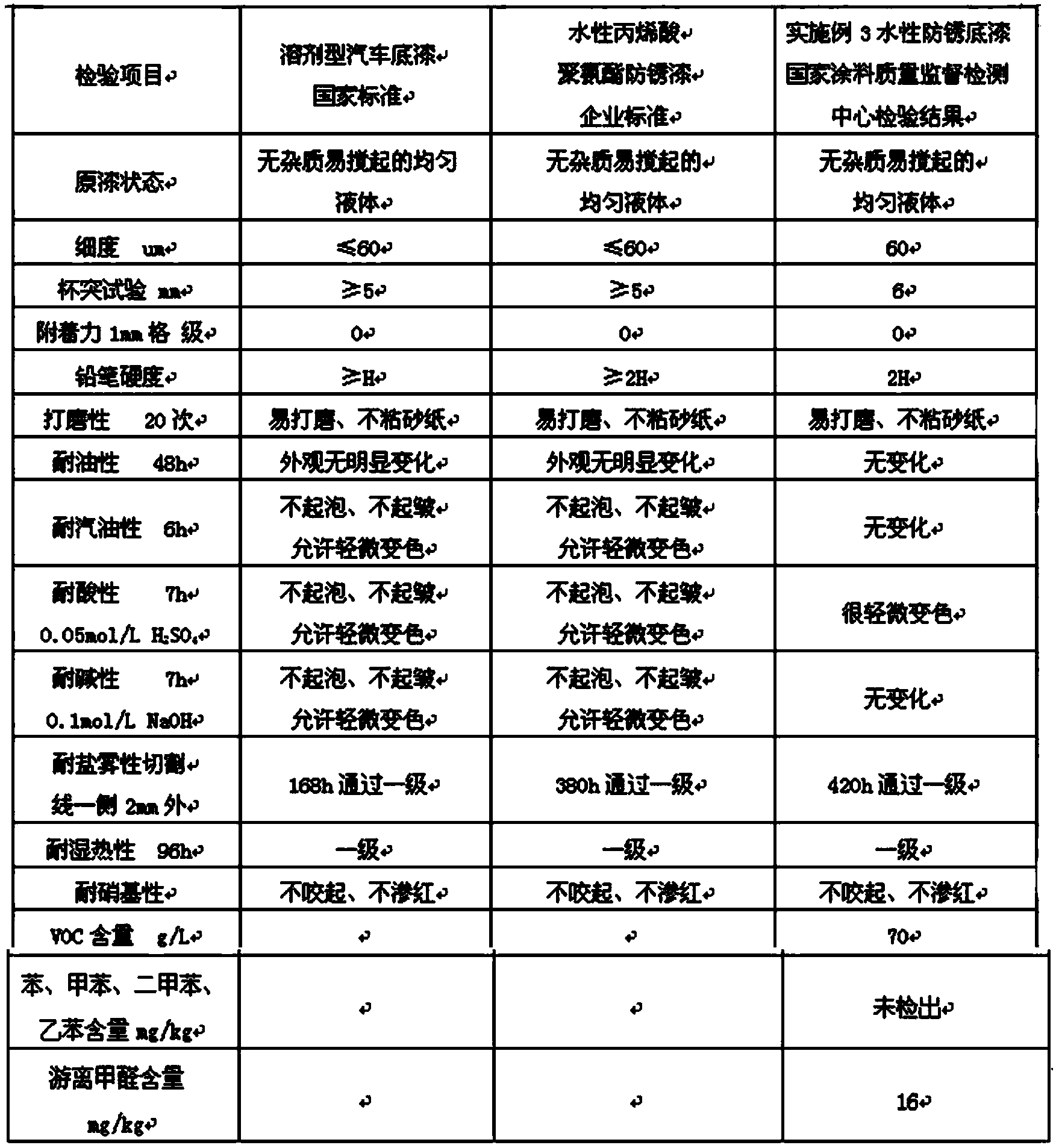

Embodiment 3

[0030] The water-based antirust primer for automobile painting provided by this embodiment is composed of A component and B component, wherein the composition of A component is shown in Table 3, and B component is Bayer VPLS2319 and Rhodia 803 The mixture of A component and B component is 12:1 by weight.

[0031] The composition of the A component of table 3 embodiment 3

[0032] A composition The A component of embodiment 3 is composed weight percentage Water-Based Acrylic Emulsion DSM XK540 resin 55 Antirust Pigment Elements 6597 Iron Red, AC111 Strontium Phosphate, Zinc Phosphate 16.1 Extender pigment Superfine talcum powder, superfine barium sulfate 24 Defoamer BYK Byk011, Byk028 0.7 Dispersant BYK191 BYK 0.8 leveling agent BYK Byk381 0.3 Substrate wetting agent Tego Tego280 0.7 Rheology Additives Tegoza Corporation Hy 0.5 Anti-flash rust agent Wally Corporation ADD458 0.8 Deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com