Preparation of water-based adhesive and preparation method of metal/polypropylene composite material

A production method and technology of composite materials, which are applied in the directions of adhesives, adhesive types, metal layered products, etc., can solve the problems of easy generation of air bubbles, reduced bonding strength, expensive dimethylamine ethanol, etc., and achieve production and use. Convenience, good environmental performance and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

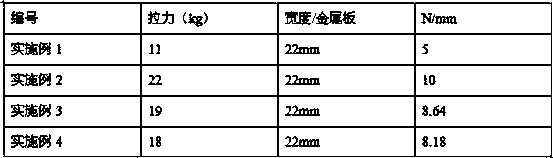

Examples

Embodiment 1

[0033] a. Graft copolymerization of chlorinated polypropylene:

[0034] (1) Add chlorinated polypropylene and organic solvent A into the container, stir and mix, and heat until the chlorinated polypropylene dissolves;

[0035] (2) Make a solution of polyoxyethylene polyoxypropylene block polyether, maleic anhydride, acrylic acid, functional monomer and initiator, and add the same organic solvent A in step (1) to dissolve;

[0036] (3) Add the solution obtained in step (2) dropwise to the solution in step (1) to react;

[0037] Among them, the parts by weight of each component are as follows: 40 parts of chlorinated polypropylene, 40 parts of organic solvent A, 10 parts of polyoxyethylene polyoxypropylene block polyether, 2 parts of maleic anhydride, 10 parts of functional monomer, acrylic acid 4 parts, 4 parts of initiator;

[0038] b. Preparation of adhesive: (1) Take the grafted product in a in a container and heat it; (2) Add pure water dropwise to step (1) and stir at hi...

Embodiment 2

[0043] a. Graft copolymerization of chlorinated polypropylene:

[0044] (1) Add chlorinated polypropylene and organic solvent A into the container, stir and mix, and heat until the chlorinated polypropylene dissolves;

[0045] (2) Make a solution of polyoxyethylene polyoxypropylene block polyether, maleic anhydride, acrylic acid, functional monomer and initiator, and add the same organic solvent A in step (1) to dissolve;

[0046] (3) Add the solution obtained in step (2) dropwise to the solution in step (1) to react;

[0047] Wherein, the parts by weight of each component are as follows: 60 parts of chlorinated polypropylene,

[0048] 60 parts of organic solvent A, 20 parts of polyoxyethylene polyoxypropylene block polyether, 4 parts of maleic anhydride, 4 parts of functional monomer, 1 part of acrylic acid, and 0.2 parts of initiator;

[0049] b. Preparation of adhesive:

[0050] (1) Take the grafted product in a in a container and heat it;

[0051](2) Add pure water dro...

Embodiment 3

[0055] a. Graft copolymerization of chlorinated polypropylene:

[0056] (1) Add chlorinated polypropylene and organic solvent A into the container, stir and mix, and heat until the chlorinated polypropylene dissolves;

[0057] (2) Make a solution of polyoxyethylene polyoxypropylene block polyether, maleic anhydride, acrylic acid, functional monomer and initiator, and add the same organic solvent A in step (1) to dissolve;

[0058] (3) Add the solution obtained in step (2) dropwise to the solution in step (1) to react;

[0059] Wherein, the parts by weight of each component are as follows: 50 parts of chlorinated polypropylene,

[0060] 50 parts of organic solvent A, 15 parts of polyoxyethylene polyoxypropylene block polyether, 3 parts of maleic anhydride, 7 parts of functional monomer, 2.5 parts of acrylic acid, 2 parts of initiator;

[0061] b. Preparation of adhesive:

[0062] (1) Take the grafted product in a in a container and heat it;

[0063] (2) Add pure water dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com