Water-based epoxy wear-resistant floor coating and preparation method and application thereof

A water-based epoxy and floor coating technology, used in epoxy resin coatings, coatings, buildings, etc., can solve the problems of general wear resistance and hardness, low service life, and inability to apply high-pressure load floors, and achieve wear and tear. Low value, improved wear resistance, effect of increased hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

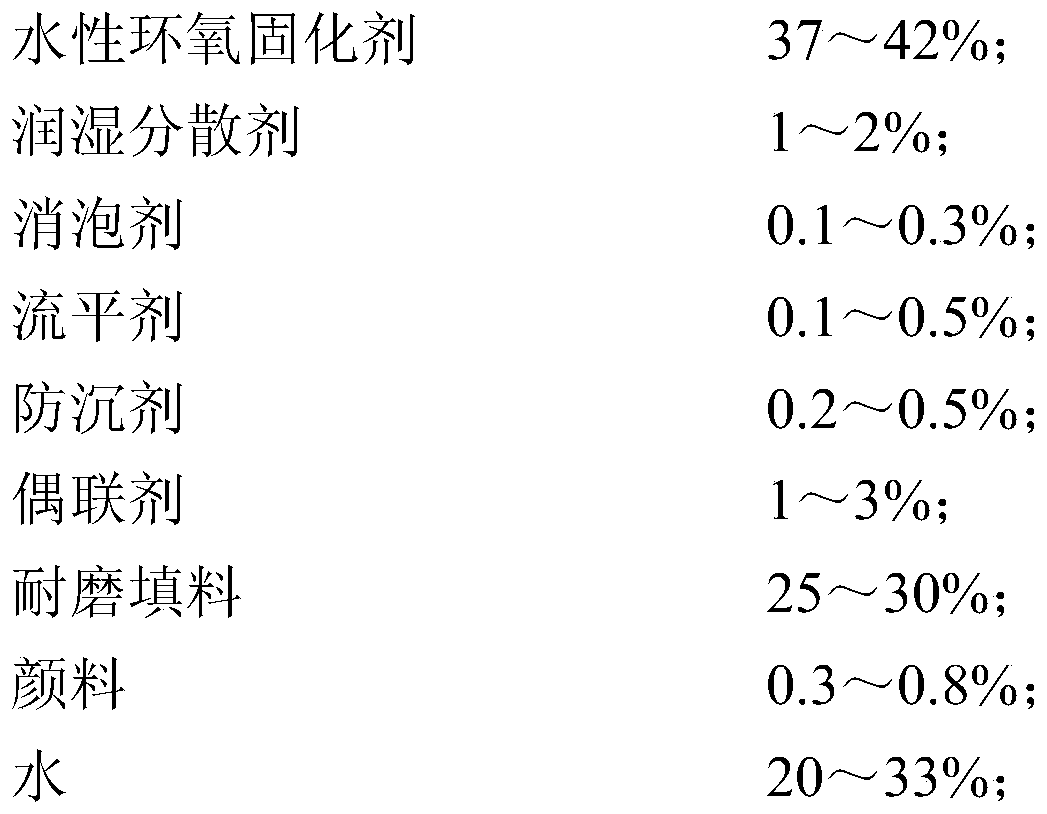

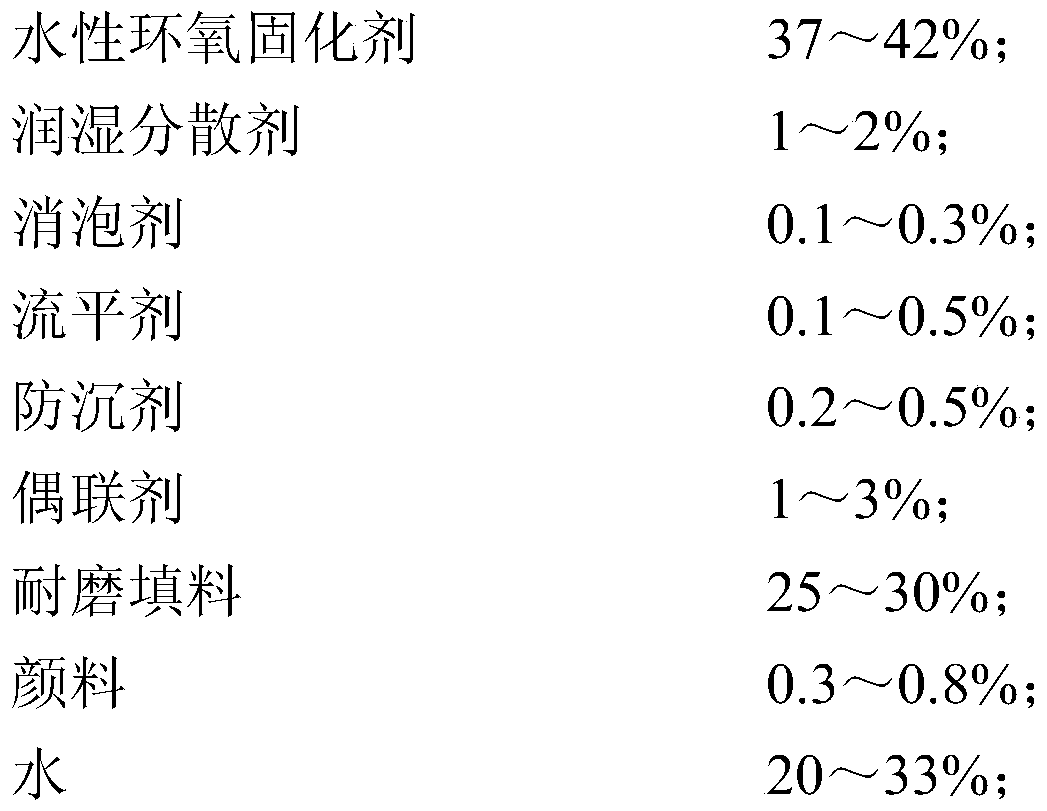

[0039] A water-based epoxy wear-resistant floor coating, comprising component A and component B, wherein the mass ratio of component A to component B is 1:4.1, and component B is water-based epoxy emulsion EPIKOTE Resion 6530-WH -53A, component A contains the following ingredients by mass percentage:

[0040] Table 1 Composition of Component A of Example 1

[0041]

[0042] The preparation method of described waterborne epoxy wear-resistant floor paint, comprises the steps:

[0043] (1) Refining stage: Add the wetting and dispersing agent, defoamer, leveling agent, coupling agent and part of water of the water-based epoxy wear-resistant floor coating into the dispersion tank, and disperse at a low speed (400r / min) 8min; then add wear-resistant fillers and pigments, disperse at high speed (900r / min) for 25min, after the dispersion is complete, enter the sand mill and grind until the fineness is ≤ 40 μm to obtain the mixture I;

[0044] (2) Paint mixing stage: Add the compo...

Embodiment 2

[0047] A water-based epoxy wear-resistant floor coating, comprising component A and component B, wherein the mass ratio of component A to component B is 1:4.2, component B is water-based epoxy emulsion CTW-6064, and the component Point A comprises the following components by mass percentage:

[0048] Table 2 Composition of Component A in Example 2

[0049]

[0050] The preparation method of described waterborne epoxy wear-resistant floor paint, comprises the steps:

[0051] (1) Refining stage: Add wetting and dispersing agent, defoamer, leveling agent, coupling agent and part of water into the dispersion tank, and disperse at low speed (300r / min) 10 minutes; then add wear-resistant fillers and pigments, disperse at high speed (800r / min) for 30 minutes, after the dispersion is completed, enter the sand mill and grind until the fineness is ≤ 40 μm to obtain the mixture I;

[0052] (2) Paint mixing stage: Add the component water-based epoxy curing agent of the water-based ep...

Embodiment 3

[0055] A water-based epoxy wear-resistant floor coating, comprising component A and component B, wherein the mass ratio of component A to component B is 1:4.5, component B is water-based epoxy emulsion STW-600, and the component Part A contains the following ingredients by mass percentage:

[0056] Table 3 Composition of Component A of Example 3

[0057]

[0058] The preparation method of described waterborne epoxy wear-resistant floor paint, comprises the steps:

[0059] (1) Refining stage: Add wetting and dispersing agent, defoamer, leveling agent, coupling agent and part of water into the dispersion tank, and disperse at low speed (500r / min) 5min; then add wear-resistant fillers and pigments, disperse at high speed (1000r / min) for 20min, after the dispersion is completed, enter the sand mill and grind to a fineness≤40μm to obtain the mixture I;

[0060] (2) Paint mixing stage: Add the component water-based epoxy curing agent of the water-based epoxy wear-resistant floo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com