Preparation method of water-based glue for ultrahigh-modulus polyethylene fibers

A polyethylene fiber, water-based technology, applied in adhesives, grafted polymer adhesives, adhesive types, etc., can solve problems such as insufficient adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

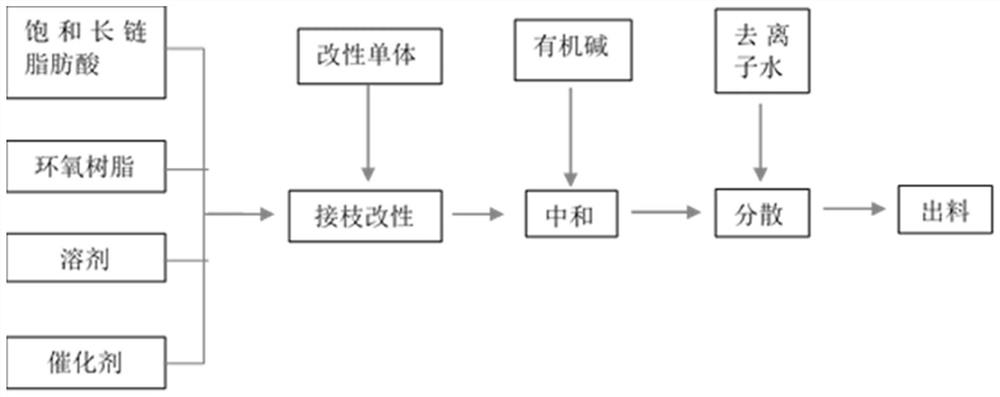

Method used

Image

Examples

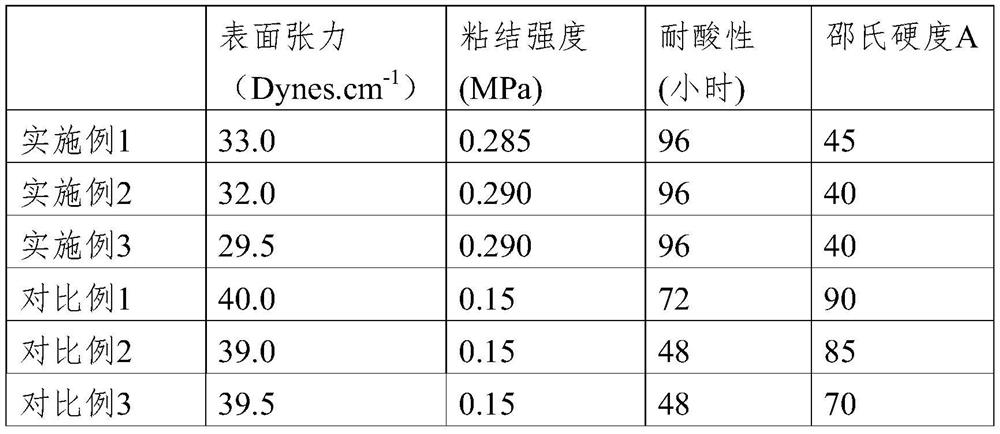

Embodiment 1

[0032] A preparation method of water-based glue for ultra-high modulus polyethylene fibers, the specific steps are as follows:

[0033] (1) Add 10 parts by weight of palmitic acid, 50 parts by weight of epoxy resin E20, 3 parts by weight of triphenylphosphine and 20 parts by weight of propylene glycol methyl ether into the flask, pass through nitrogen protection, and heat to 100±5°C , keep warm for 2 hours;

[0034] (2) Heating up to 110±5°C, dropwise adding 3 parts by weight of single-ended vinyl silicone oil CH 2 =CH-Si(CH 3 ) 2 O[(CH 3 ) 2 SiO] 10 CH 3 ) 2 Si-CH 3 , 10 parts by weight of butyl acrylate, 2 parts by weight of octafluoropentyl methacrylate monomer, 3 parts by weight of KH570, and 2 parts by weight of benzoyl peroxide, the mixture is dripped in 3 hours;

[0035] (3) Add 0.5 parts by weight of benzoyl peroxide to continue the reaction for 2 hours, and cool down to 65±5°C;

[0036] (4) Add 3 parts by weight of N,N-dimethylethanolamine and react for 30 m...

Embodiment 2

[0039] A preparation method of water-based glue for ultra-high modulus polyethylene fibers, the specific steps are as follows:

[0040] (1) Add 10 parts by weight of stearic acid, 50 parts by weight of epoxy resin E12, 3 parts by weight of triphenylphosphine and 20 parts by weight of propylene glycol methyl ether into the flask, pass through nitrogen protection, and heat to 100±5°C , keep warm for 2 hours;

[0041] (2) Raise the temperature to 110±5°C, and add 4 parts by weight of single-ended vinyl silicone oil CH 2 =CH-Si(CH 3 ) 2 O[(CH 3 ) 2 SiO] 10 CH 3 ) 2 Si-CH 3 , a mixture of 10 parts by weight of butyl acrylate, 1 part by weight of octafluoropentyl methacrylate monomer, 4 parts by weight of KH570, and 1 part by weight of benzoyl peroxide, dripped in 3 hours;

[0042](3) Add 1 part by weight of benzoyl peroxide to continue the reaction for 2 hours, and cool down to 65±5°C;

[0043] (4) Add 4 parts by weight of N,N-dimethylethanolamine and react for 30 minutes...

Embodiment 3

[0046] A preparation method of water-based glue for ultra-high modulus polyethylene fibers. The method of in-situ polymerization is adopted, and the specific steps are as follows:

[0047] (1) Add 5 parts by weight of arachidic acid, 50 parts by weight of epoxy resin E20, 1 part by weight of triphenylphosphine and 20 parts by weight of propylene glycol methyl ether into the flask, pass through nitrogen protection, and heat to 100±5°C, keep warm for 2 hours;

[0048] (2) Raise the temperature to 110±5°C, and add 4 parts by weight of vinyl silicone oil CH at a uniform speed 2 =CH-Si(CH 3 ) 2 O[(CH 3 ) 2 SiO] 10 CH 3 ) 2 SiCH 3 , the mixture of 10 parts by weight of butyl acrylate, 1 part by weight of octafluoropentyl methacrylate monomer, 4 parts by weight of silane coupling agent KH570, and 2 parts by weight of benzoyl peroxide, dripped in 3 hours;

[0049] (3) Add 1 part by weight of benzoyl peroxide to continue the reaction for 2 hours, and cool down to 65±5°C;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com