Magnetic adsorbent as well as preparation thereof and treatment method to actinide element waste liquid

A technology of magnetic adsorbent and actinide elements, which is applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, magnetic field/electric field water/sewage treatment, etc., which can solve the cumbersome material preparation process, high synthesis operation requirements, and harsh reaction conditions and other problems to achieve the effect of convenient operation, shortened operation cycle and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment is the preparation method of magnetic adsorbent, comprising the following steps:

Embodiment 11

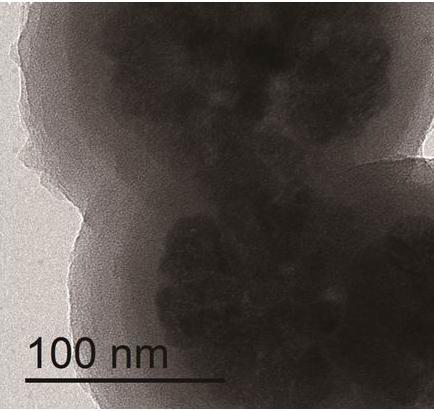

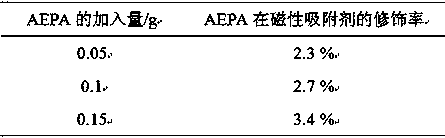

[0042] 0.1 g polydopamine / silica-coated magnetic microspheres were dispersed in 9.5 mmol / L-20.5 mmol / L aqueous solution of 100 mL trishydroxymethylaminomethane, and 0.1 g aminoethylphosphonic acid ligand was added slowly, Adjust the pH range of the solution to 8.5~10.0, and control the temperature of the system at 60°C~70°C, first conduct the heating and reflux reaction for 4.0h~6.0h, and then stir overnight at room temperature. The magnetic adsorbent in the suspension was separated by a magnet, washed alternately with water and ethanol, and then vacuum-dried at 60°C for 12 h to obtain the desired magnetic adsorbent with a core-shell structure. The transmission electron microscope pictures of the magnetic adsorbent are shown in figure 1 As shown, it can be clearly observed that the magnetic adsorbent has a double-layer core-shell structure, the thickness of the inner silica shell is 20 nm, and the thickness of the outer polydopamine shell is 20 nm. However, the organic ligan...

Embodiment 12

[0044] The amount of 0.1 g polydopamine / silica-coated magnetic microspheres dispersed in 9.5 mmol / L~20.5 mmol / L tris aqueous solution is 80 mL and 120 mL respectively, and other operating steps are the same as in the examples 1.1. Compared with Example 1.1, the morphology of the prepared magnetic adsorbent with core-shell structure has no obvious change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com