Preparation of a macromolecular compatibilizer for rubber and its application in acrylate rubber/nitrile rubber alloy elastomer

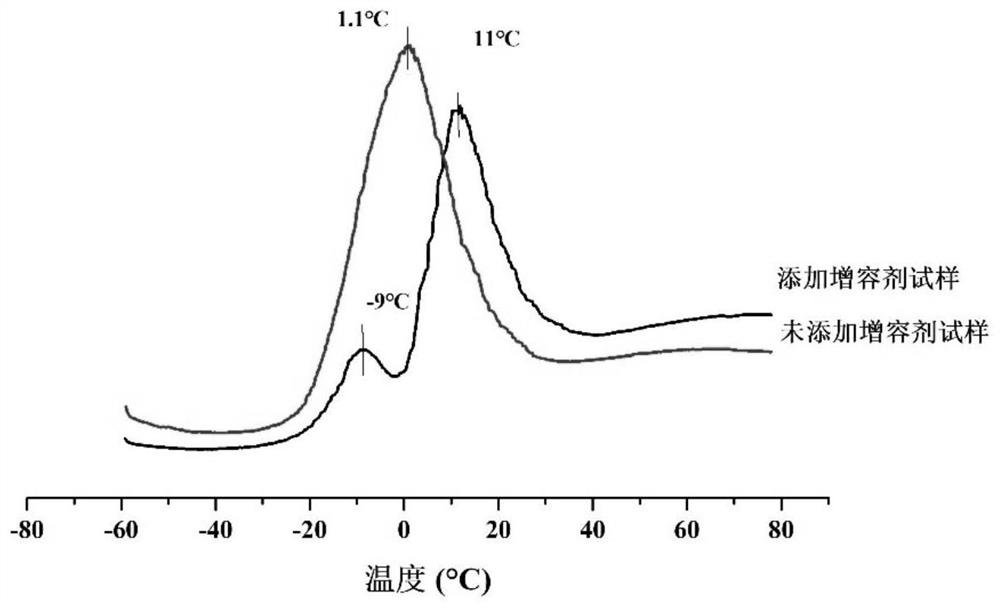

A technology of acrylate and nitrile rubber, which is used in the application of acrylate rubber/nitrile rubber alloy elastomers, and the preparation of rubber with macromolecular compatibilizers, which can solve the problem that the mechanical properties of vulcanizates cannot be reached and cannot be formed. Interpenetrating cross-linked network IPN and other issues, to achieve the effect of excellent oil resistance, simple and easy operation, and excellent heat aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw materials in this experimental example are: ACM masterbatch formula (mass fraction): ACM raw rubber 100, stearic acid SA 2, antioxidant 445 3, release agent 935P 3, anti-scorch agent PVT 0.5, high wear-resistant carbon black N55050, curing agent HMDC1.2, accelerator XL-602.

[0033] NBR masterbatch formula (mass fraction): NBR raw rubber 100, zinc oxide ZnO 5, stearic acid SA 2, antioxidant RD1, antioxidant 4010NA 1, plasticizer DOP 10, accelerator NOBS 1.1, accelerator DM 1.1 , Accelerator DTDM 1.1.

[0034] ACM raw rubber and NBR (acrylonitrile content 25%-41%) raw rubber are used together in the ratio of ACM / NBR=80 / 20.

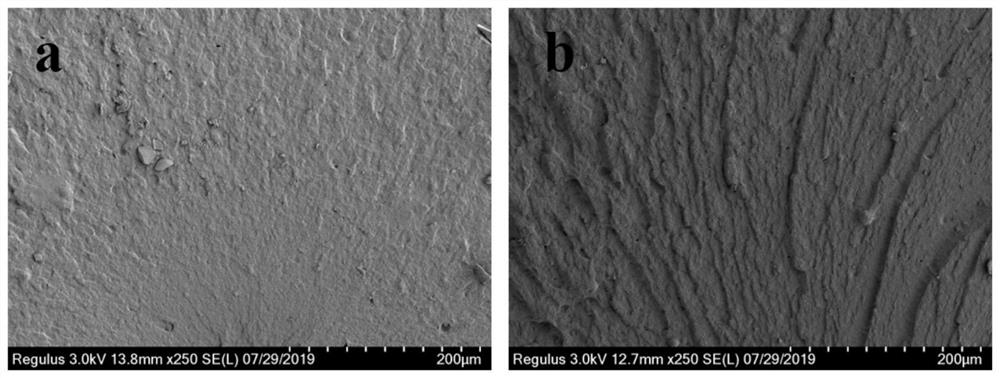

[0035] This example is a blend of ACM and NBR without adding a compatibilizer. The specific implementation steps are as follows:

[0036] (1) Add ACM raw rubber into the open mill, adjust the roll distance to 1mm, add various small materials of acrylic rubber after wrapping the rolls, and finally add vulcanizing agent and vulcanizing aid, a...

Embodiment 2

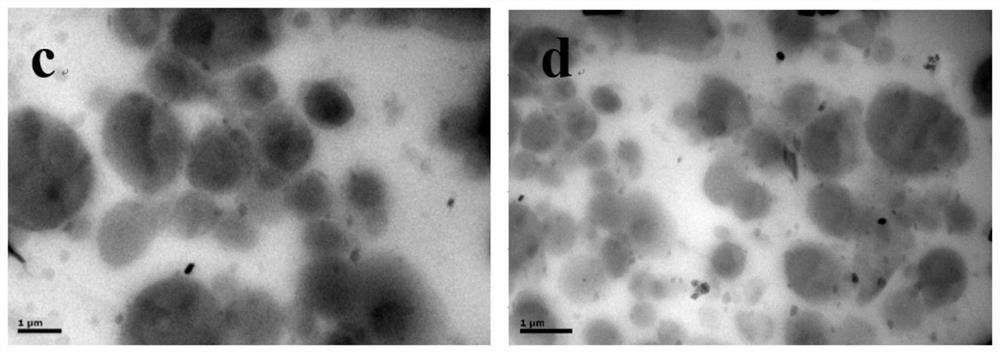

[0041] The raw material of macromolecule compatibilizer in the present embodiment consists of: 100 mass parts of epoxy-type acrylate rubber, 25 mass parts of carboxyl-terminated nitrile rubber (CN-25), plasticizer A dibutyl terephthalate 5 parts by mass, catalyst B octadecyldimethyl tertiary amine 0.63 parts by mass.

[0042] The preparation method of macromolecule compatibilizer in the present embodiment is as follows:

[0043] 1. Add the weighed epoxy acrylate rubber (ACM-EPG) masticate and plasticizer A into the internal mixer respectively, start the rotor to mix, and then add the measured amount of liquid carboxyl-terminated butyl at 40-50°C Nitrile rubber (LX-NBR), under the rotation of the rotor, slowly raise the temperature to 70-80°C and continue to knead evenly, then gradually raise the temperature to 90-110°C and speed up the speed to obtain the mixed rubber material M;

[0044] 2. Add tertiary amine catalyst B to the mixture M obtained in step 1, continue to heat u...

Embodiment 3

[0049] The raw material of macromolecule compatibilizer in the present embodiment is constituted as: epoxidized acrylate rubber 100 mass parts, carboxyl-terminated nitrile rubber (CN-15) 25 mass parts, plasticizer A dibutyl terephthalate 5 parts by mass, catalyst B octadecyldimethyl tertiary amine 0.63 parts by mass.

[0050] The preparation method of macromolecule compatibilizer in the present embodiment is as follows:

[0051] 1. Add the weighed epoxy acrylate rubber (ACM-EPG) masticate and plasticizer A into the internal mixer respectively, start the rotor to mix, and then add the measured amount of liquid carboxyl-terminated butyl at 40-50°C Nitrile rubber (LX-NBR), under the rotation of the rotor, slowly raise the temperature to 70-80°C and continue to knead evenly, then gradually raise the temperature to 90-110°C and speed up the speed to obtain the mixed rubber material M;

[0052] 2. Add tertiary amine catalyst B to the mixture M obtained in step 1, continue to heat u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com