Water-based non-isocyanate polyurethane and preparation method thereof

A water-based non-isocyanate and non-isocyanate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve threats, environmental pollution, human health and other problems, and achieve the effect of low VOCs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

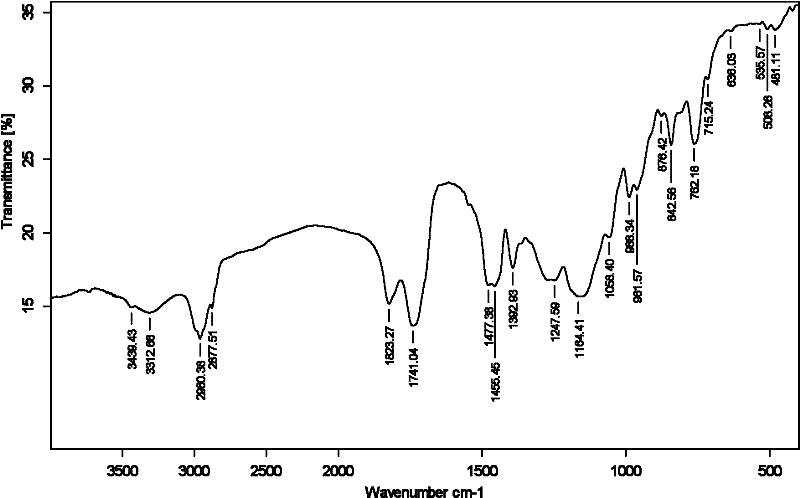

Embodiment 1

[0027] Add 30g of isopropanol to a four-neck flask equipped with mechanical stirring, reflux condenser, thermometer and ventilation tube, pass nitrogen gas for about 30min and heat to 80°C, then dropwise add the monomer mixture (methyl methacrylate 10.8g, Butyl acrylate 11.6g, methacrylic acid 1.8g, methacrylic acid cyclocarbonate 9.17g, AIBN: 2wt%, dodecyl mercaptan 5.7wt%), dripping within 1h. Insulate and react for 4 hours, cool down to 50-70°C, add triethylamine to neutralize to pH = 7-8, add deionized water to a solid content of about 35% at a stirring speed of 600rpm, keep warm at 50-60°C for 15-30min, and then Add 1.6g of ethylenediamine, react at 25°C for 4-10h, and discharge to obtain NIPU emulsion.

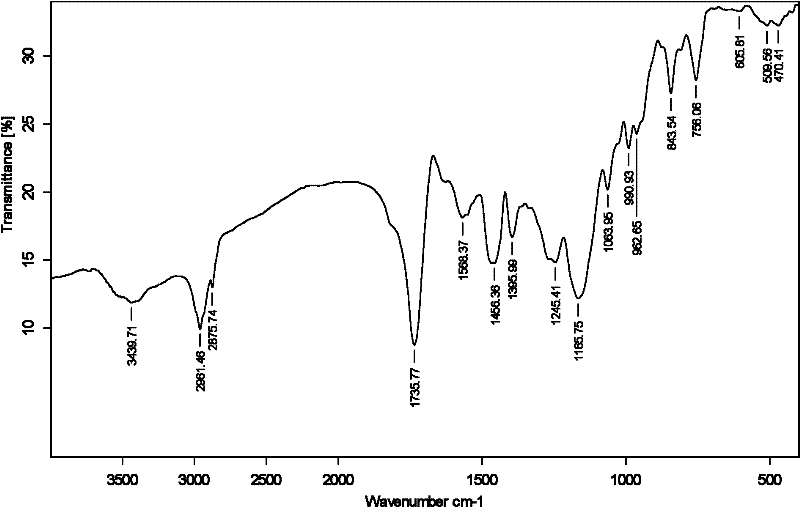

Embodiment 2

[0029] Add 30 g of ethanol to a four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and ventilation tube, pass nitrogen gas for about 30 minutes and heat to 80 ° C, then dropwise add the monomer mixture (methyl methacrylate 13.8 g, butyl acrylate 13.77g of ester, 1.8g of methacrylic acid, 4g of methacrylic acid cyclocarbonate, AIBN: 2wt%, dodecyl mercaptan 7wt%), the drop was completed within 1.5h. Insulate and react for 4 hours, cool down to 50-70°C, add N,N-dimethylethanolamine to neutralize to pH = 7-8, add deionized water at a stirring speed of 400rpm until the solid content is about 35%, keep at 50-60°C After 15-30 minutes, the solvent ethanol was distilled off under reduced pressure, and the solid content was readjusted to about 35% with deionized water, then 1.35 g of hexamethylenediamine was added, reacted at 40°C for 4-10 hours, and the NIPU emulsion was obtained after discharging.

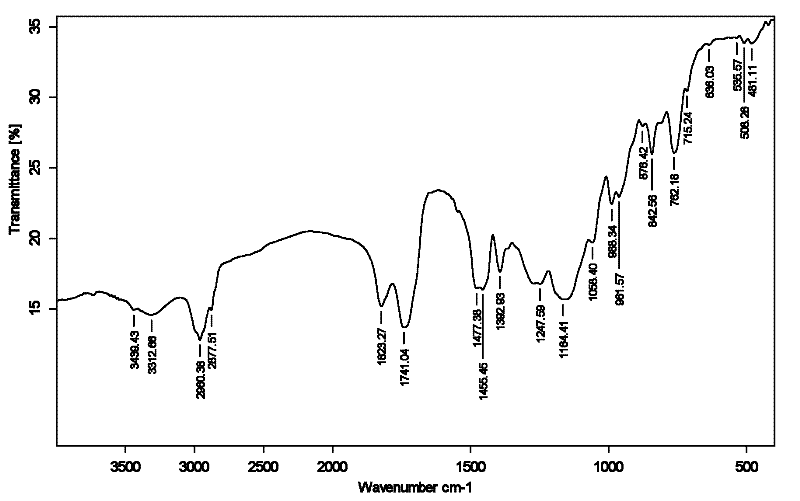

Embodiment 3

[0031] Add 30g of tetrahydrofuran into a four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and ventilation tube, pass nitrogen gas for about 30min and heat to reflux, then dropwise add the monomer mixture (methyl methacrylate 10g, butyl acrylate 13.6 g, 3.3 g of hydroxyethyl methacrylate, 2.1 g of methacrylic acid, 4 g of methacrylic acid cyclocarbonate, AIBN: 1 wt %, dodecyl mercaptan 8 wt %), and drop it within 2 hours. Keep the reaction at 70°C for 6 hours, lower the temperature to 50-60°C, add triethanolamine to neutralize to pH=7-8, add deionized water at a stirring speed of 500rpm until the solid content is about 35%, keep at 50-60°C for 15-30min, Then add 1.7g of triethylenetetramine, react at 50°C for 4-10h, and discharge to obtain NIPU emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com