A kind of one-component normal temperature curing water-based anticorrosion resin and preparation method thereof

An anti-corrosion resin, curing technology at room temperature, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of insufficient cross-linking density, limited corrosion resistance, water whitening resistance, salt spray resistance and heat resistance to be improved, etc. The effect of increasing joint density, improving self-drying at room temperature, and improving the compactness of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

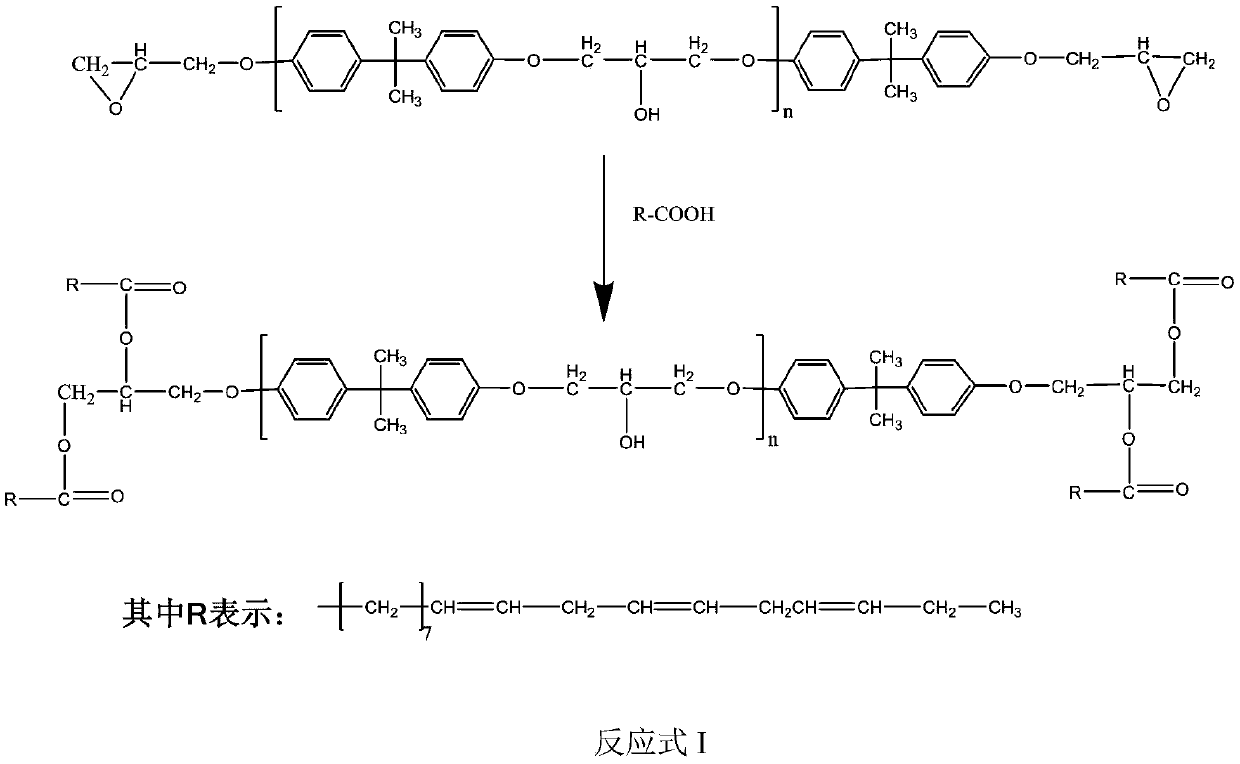

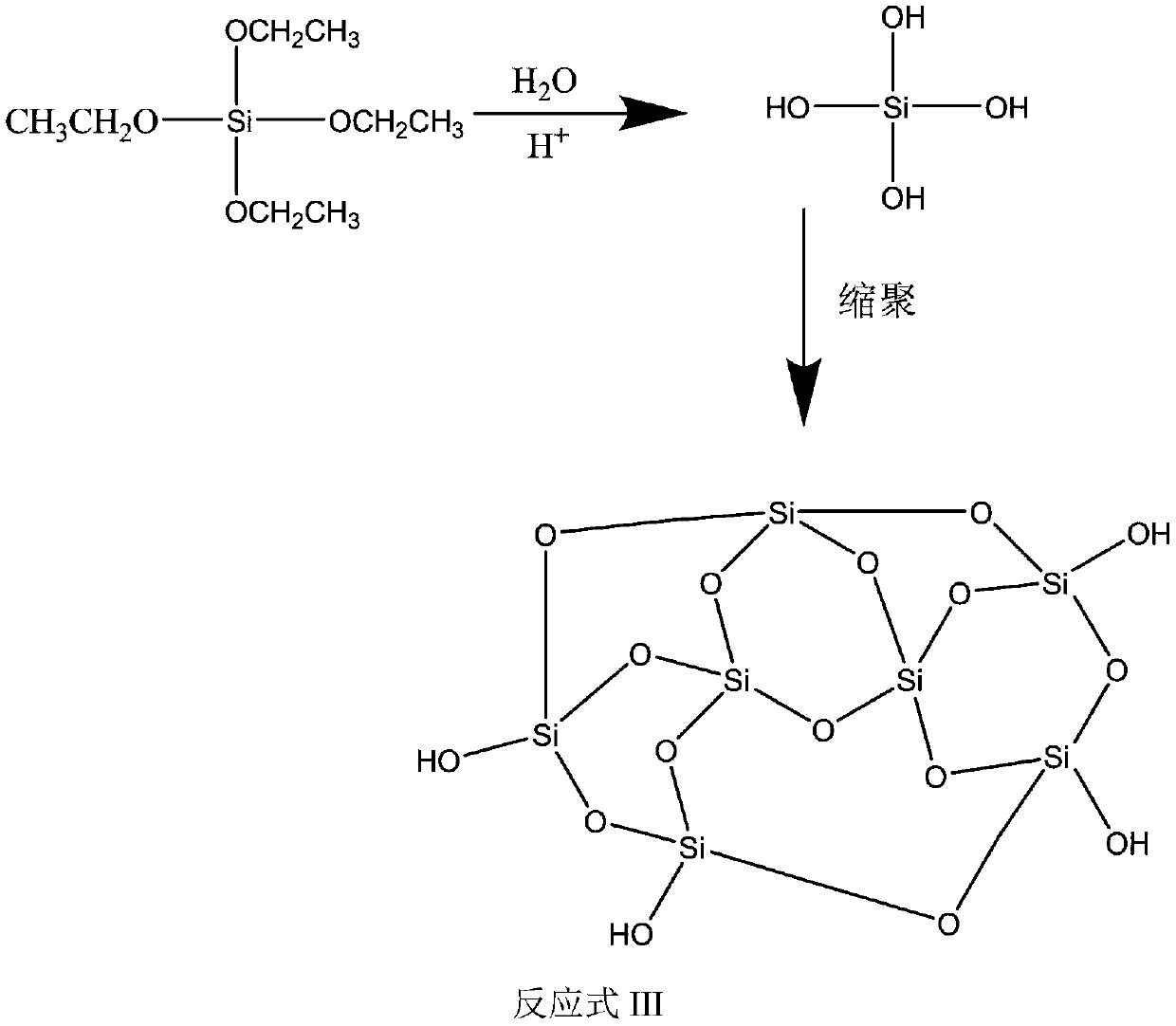

[0033] Embodiment 1: the preparation of one-component normal temperature curing water-based anticorrosion resin

[0034] (1) Add 335g of linolenic acid to a 1000mL three-neck round bottom flask, and heat to 150°C; add 150g of bisphenol A epoxy resin E-20, and keep it at 150°C for 2 hours; heat up to 220°C, and then add 150g of E-20, stir to dissolve and add 3g of stannous octoate to make it transparent, take a sample every hour to measure the acid value, until the acid value is <10mg KOH / g, the esterification reaction is completed, cool down and add the mixture of n-butanol and propylene glycol methyl ether, n-butanol Alcohol: propylene glycol methyl ether (v / v)=1:1, make it control the solid content of epoxy ester to be 60%, obtain epoxy ester.

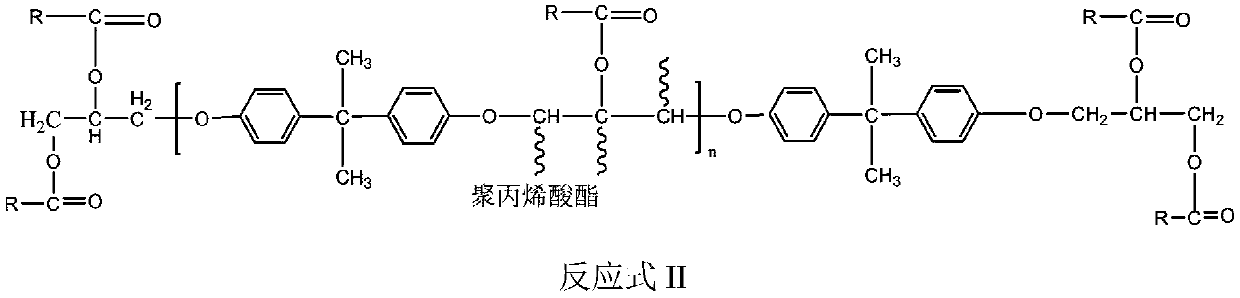

[0035] (2) Take 150g of the above-mentioned epoxy ester and put it into a 1000mL three-neck bottle, raise the temperature to 120°C, weigh 40g of styrene, 35g of ethyl acrylate, 15g of acrylic acid, and 4g of dibenzoyl peroxide (BPO) ...

Embodiment 2

[0038] Embodiment 2: the preparation of one-component normal temperature curing water-based anticorrosion resin

[0039] (1) Add 200g of linoleic acid to a 1000mL three-neck round bottom flask, heat it to 140°C, add 190g of bisphenol A epoxy resin E-12, and keep it at 140°C for 2 hours; raise the temperature to 200°C, add the remaining 190g of E-12 -12, Stir to dissolve and add 1.9g of monobutyltin oxide, take a sample every hour to measure the acid value, until the acid value is <10mg KOH / g, the esterification reaction is completed, cool down and add n-butanol and ethylene glycol butyl ether Mixture, n-butanol:ethylene glycol butyl ether (v / v)=2:1, make it control the solid content of epoxy ester to be 55%, obtain epoxy ester.

[0040](2) Take 180g of the above-mentioned epoxy ester and put it into a 1000mL three-neck bottle, heat up to 120°C, weigh 50g of vinyl acetate, 45g of ethyl acrylate, 18g of methacrylic acid, and 5g of dibenzoyl peroxide (BPO) and mix well , and the...

Embodiment 3

[0043] Embodiment 3: the preparation of one-component normal temperature curing water-based anticorrosion resin

[0044] (1) Add 465g of linolenic acid to a 1000mL three-neck round bottom flask, heat it to 160°C, add 167g of bisphenol A epoxy resin E-20, and keep it at 160°C for 2 hours; raise the temperature to 210°C, add the remaining 167g E -20, Stir to dissolve and add 5.3g of dibutyltin, take a sample every hour to measure the acid value, until the acid value is <10mg KOH / g, the esterification reaction is complete, cool down and add the mixture of n-butanol and propylene glycol methyl ether, n-butanol : Propylene glycol methyl ether (v / v)=1.5:1, obtain epoxy ester, make it control epoxy ester solid content to be 65%.

[0045] (2) Take 140g of the above-mentioned epoxy ester and put it into a 1000ml three-neck bottle, heat up to 115°C, weigh 38g of styrene, 35g of butyl acrylate, 12g of methacrylic acid, and 3.5g of dibenzoyl peroxide (BPO) and mix well , and then added d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com