Preparation method of epoxy modified thermosetting acrylic waterborne resin

A water-based and epoxy-modified technology of acrylic acid, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of insufficient chemical resistance and poor fullness, improve fullness and chemical resistance, and realize water-based Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

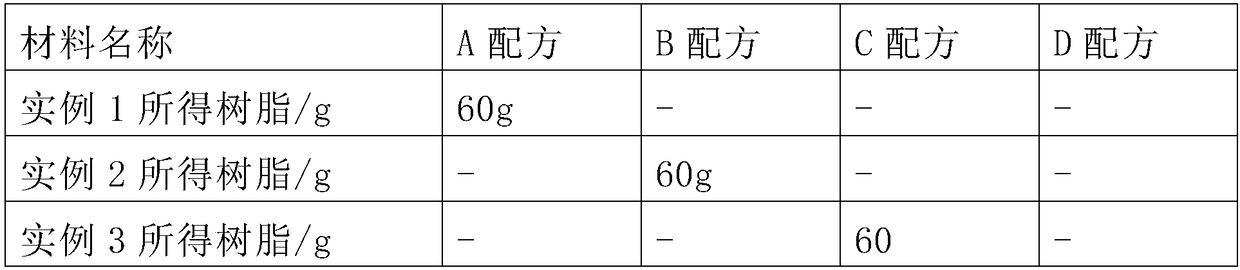

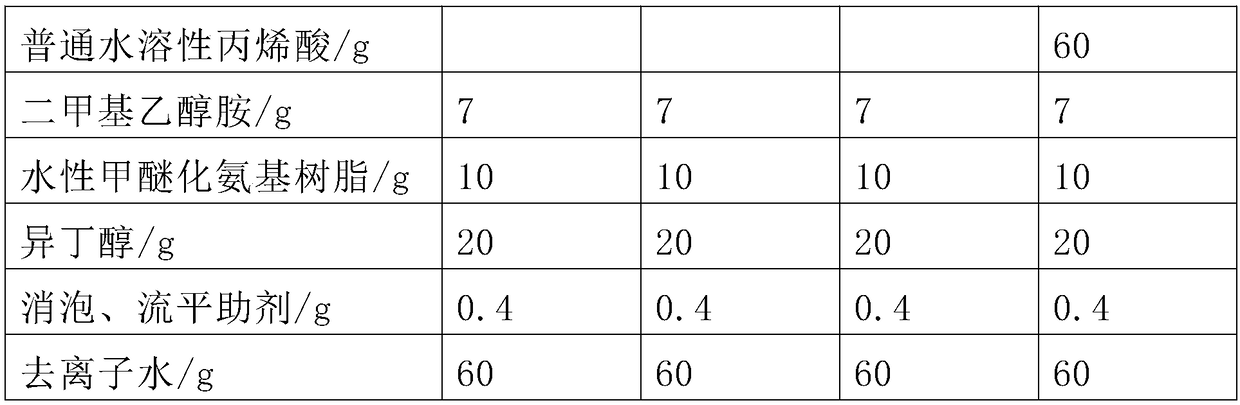

Examples

Embodiment 1

[0034] (1) Mix the following components to obtain material A: E-12 epoxy resin 100g, propylene glycol methyl ether 300g, isobutanol 100g, ethylene glycol monobutyl ether 150g; mix the following components to obtain material B: acrylic acid 50g, Butyl acrylate 200g, isooctyl acrylate 80g, hydroxypropyl acrylate 50g, styrene 100g, methyl methacrylate 100g, tert-butyl peroxybenzoate 10, benzoyl peroxide 1g; 5 g of butyl ester and 20 g of ethylene glycol monobutyl ether are mixed to obtain material C;

[0035] (2) A material is put into a four-necked flask and heated to reflux;

[0036] (3) Put material B into the beaker, stir evenly, add dropwise to the four-necked flask, the dropwise addition time is 3 hours, heat up and reflux for two hours;

[0037] (4) Add material C under reflux, finish adding in 30 minutes, and keep warm for 3 hours under reflux;

[0038] (5) Cooling and discharging to obtain an epoxy-modified thermosetting acrylic water-based resin.

Embodiment 2

[0040] (1) Mix the following components to obtain material A: E-20 epoxy resin 200g, propylene glycol methyl ether 100g, isobutanol 250g, ethylene glycol monobutyl ether 350g; mix the following components to obtain material B: acrylic acid 150g, 50g of butyl acrylate, 250g of isooctyl acrylate, 50g of hydroxypropyl acrylate, 100g of styrene, 100g of methyl methacrylate, 1g of tert-butyl peroxybenzoate, 12g of benzoyl peroxide; mix the following components to get Material C: benzoyl peroxide 2g, isobutanol 25g.

[0041] (2) A material is put into a four-necked flask and heated to reflux;

[0042] (3) Put material B into the beaker, stir evenly, add dropwise to the four-necked flask, the dropwise addition time is 3 hours, heat up and reflux for two hours;

[0043] (4) Add material C under reflux, finish adding in 30 minutes, and keep warm for 3 hours under reflux;

[0044] (5) Cooling and discharging to obtain an epoxy-modified thermosetting acrylic water-based resin.

Embodiment 3

[0046] (1) Mix the following components to obtain material A: E-51 epoxy resin 300g, propylene glycol methyl ether 200g, isobutanol 150g, ethylene glycol monobutyl ether 250g; mix the following components to obtain material B: acrylic acid 80g, Butyl acrylate 100g, isooctyl acrylate 150g, hydroxypropyl acrylate 120g, styrene 80g, methyl methacrylate 150g, tert-butyl peroxybenzoate 5g, benzoyl peroxide 6g; 3 g of butyl ester and 20 g of propylene glycol methyl ether were mixed to obtain material C.

[0047] (2) A material is put into a four-necked flask and heated to reflux;

[0048] (3) Put material B into the beaker, stir evenly, add dropwise to the four-necked flask, the dropwise addition time is 3 hours, heat up and reflux for two hours;

[0049] (4) Add material C under reflux, finish adding in 30 minutes, and keep warm for 3 hours under reflux;

[0050] (5) Cooling and discharging to obtain an epoxy-modified thermosetting acrylic water-based resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com