Method for preparing blocked polyurethane-epoxy resin composite emulsifier

A technology of epoxy resin and composite emulsion, which is applied in the field of coating science, can solve the problems of reducing emulsion stability, failing to meet anti-corrosion requirements, and limited amount of epoxy resin, so as to increase the amount of modification, improve the performance of anti-corrosion candles, reduce The effect of crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

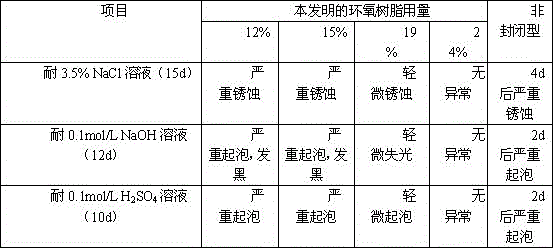

Examples

Embodiment Construction

[0020] The specific implementation technical solutions of the present invention will be described in further detail below in conjunction with the examples.

[0021] A preparation method of closed polyurethane-epoxy resin composite emulsion, comprising the following steps:

[0022] 1) Ring opening of epoxy resin

[0023] Weigh 50g of bisphenol A type epoxy resin and dissolve it in a mixed solvent of N-methylpyrrolidone and acetone, add 11.04g of diethanolamine after complete dissolution, and react at 75-80°C for about 8 hours to cool and discharge;

[0024] 2) Synthesis of closed polyurethane-epoxy resin composite emulsion

[0025] Weigh 12g of toluene diisocyanate and 5.30g of polyether diol, react at 75°C until the -NCO value is close to the theoretical value, and then gradually add 1,4-butanediol, Dimethylolpropionic acid was reacted until the -NCO value was close to the theoretical value, and the end-NCO polyurethane prepolymer was prepared, and then the blocking agent me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com