Method for preparing sheet-like microcrystal cellulose and modification processing method

A technology of microcrystalline cellulose and a treatment method, which is applied in the field of preparation and surface modification treatment of flaky microcrystalline cellulose, can solve the problems that it is not suitable for large-scale production and has high requirements in the production process, and achieves improved dispersibility, The effect of maintaining physical and mechanical properties and maintaining excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare 200 ml of sulfuric acid solution with a volume ratio of 1:1, add 20.5 g of lignocellulose, stir rapidly at 60°C for 5 minutes, then add 0.8 ml of acetic anhydride, adjust the temperature to 40°C, stir for 60 minutes, wash, filter, and dry Dry and grind to obtain surface-modified flaky microcrystalline cellulose.

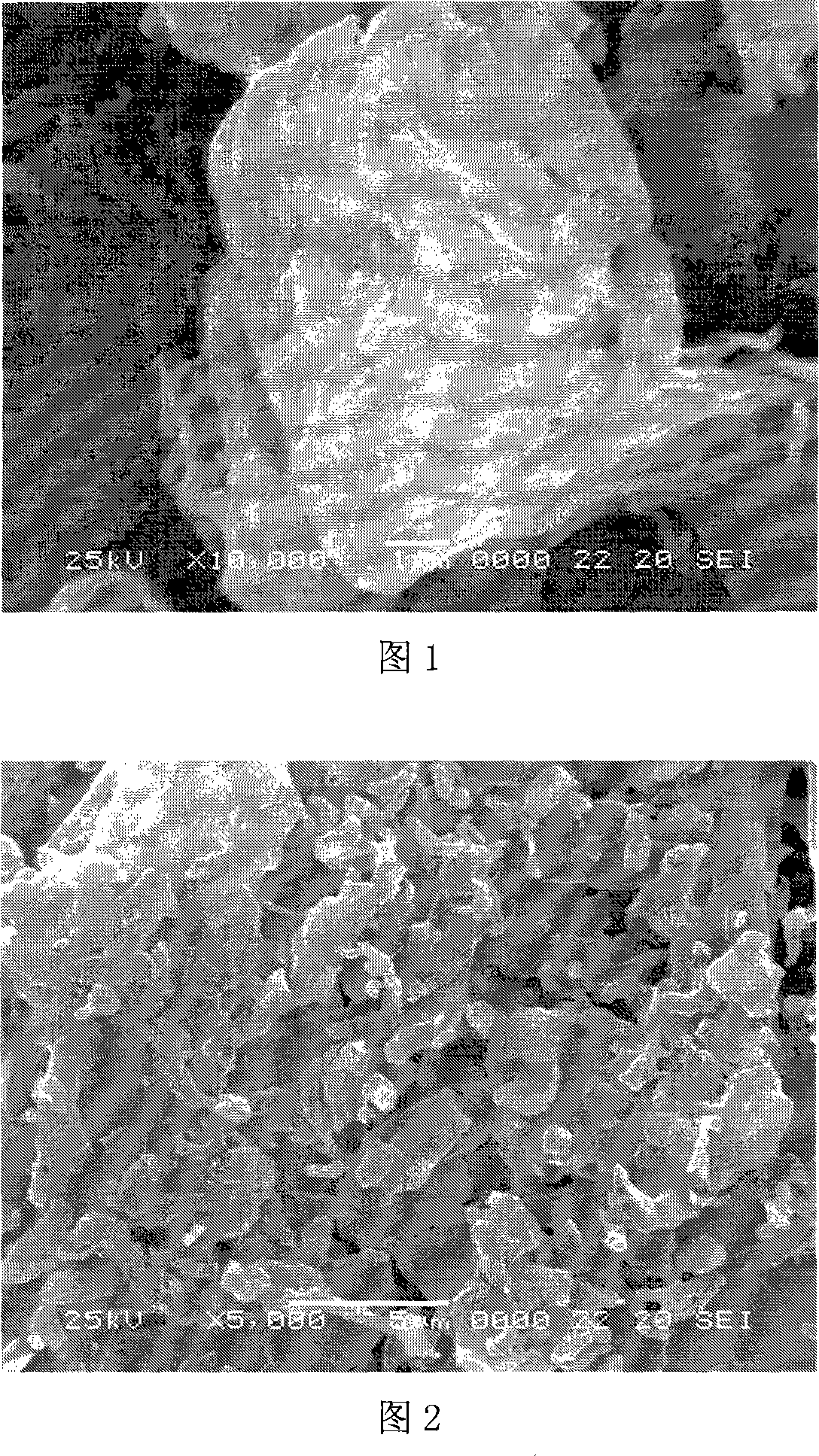

[0026] The scanning electron microscope observation results of microcrystalline cellulose obtained after acid treatment in the examples are shown in FIG. 1 . The scanning electron microscope observation results of the microcrystalline cellulose modified by adding acetic anhydride are shown in Fig. 2 . It can be clearly seen from the morphology that the microcrystalline cellulose is in the form of flakes.

Embodiment 2

[0028] Prepare 100 milliliters of sulfuric acid solution with a volume ratio of 1:1.5, add 15.0 grams of lignocellulose, stir rapidly at 40°C for 15 minutes, then add 0.2021 grams of sodium dodecylbenzenesulfonate, stir rapidly for 30 minutes, filter, wash, put Dry in a drying oven and grind.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com