Small tube shed pre-grouting method

A technology of advanced grouting and pipe shed, applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems of high construction cost, flowing sand layer, large excavation volume, etc., and improve the quality of support and construction Guarantee, the effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

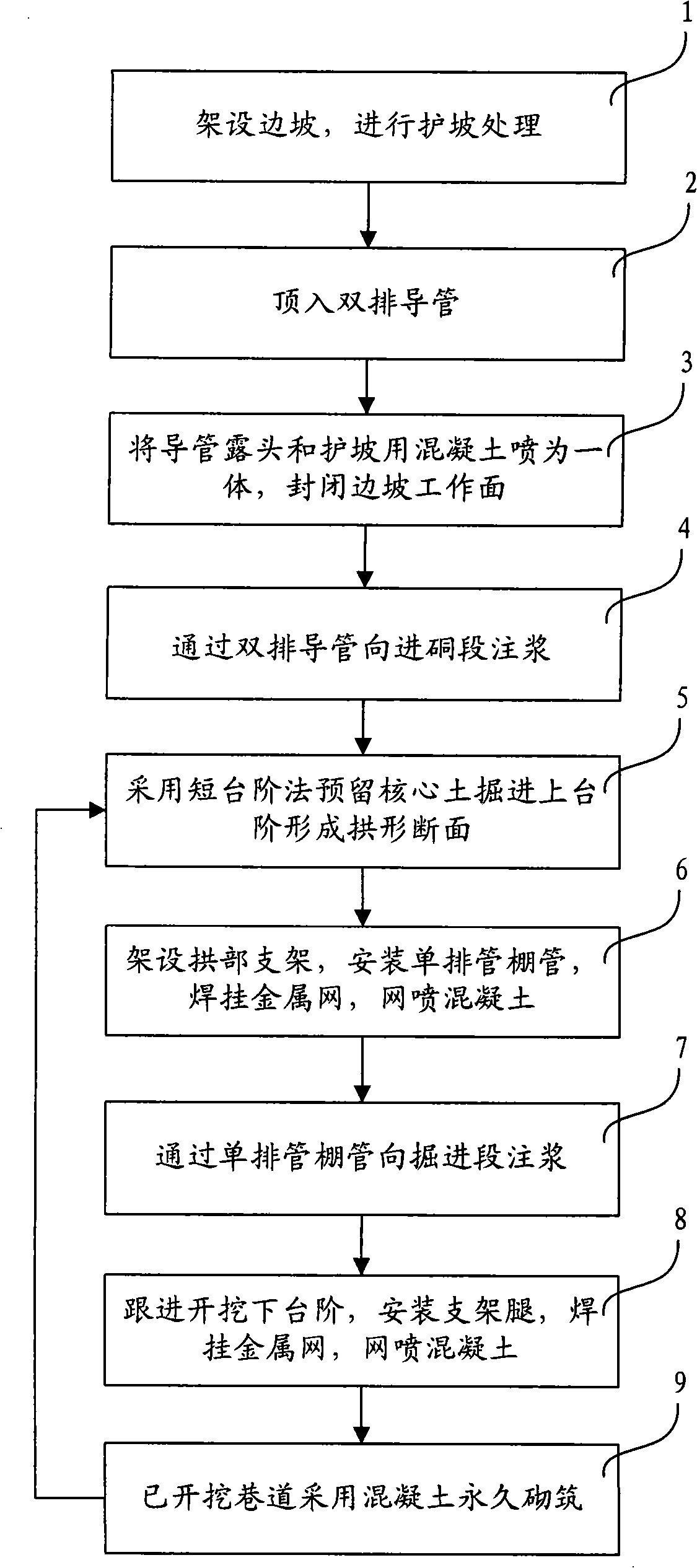

[0034] figure 1 Implementation flow chart for the present invention. Such as figure 1 Shown, the advance grouting method of the small tube shed of the present invention comprises:

[0035] Step 1, set up the side slope, and carry out slope protection treatment;

[0036] Step 2, push into the double-row conduit;

[0037] Step 3. Spray the conduit outcrop and slope protection with concrete, and close the slope working face;

[0038] Step 4, grouting to the inlet section through double rows of conduits;

[0039] Step 5, using the short step method to reserve the core soil to excavate the upper step to form an arched section;

[0040] Step 6. Set up the arch support on the arch section, install a single row of pipe shed pipes on the arch support, weld and hang metal mesh on the arch support, and spray concrete with the mesh to form the arch support;

[0041] Step 7, grouting to the excavation section through the single-row pipe shed pipe;

[0042] Step 8. Follow up the exca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com