Different repair and reinforcement method based on classification of well wall rupture degree

A shaft wall and horizontal technology, applied in the field of mine construction, can solve problems such as economic loss, incomplete formulation of support schemes, lack of understanding of limitations and advantages, etc., and achieve the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

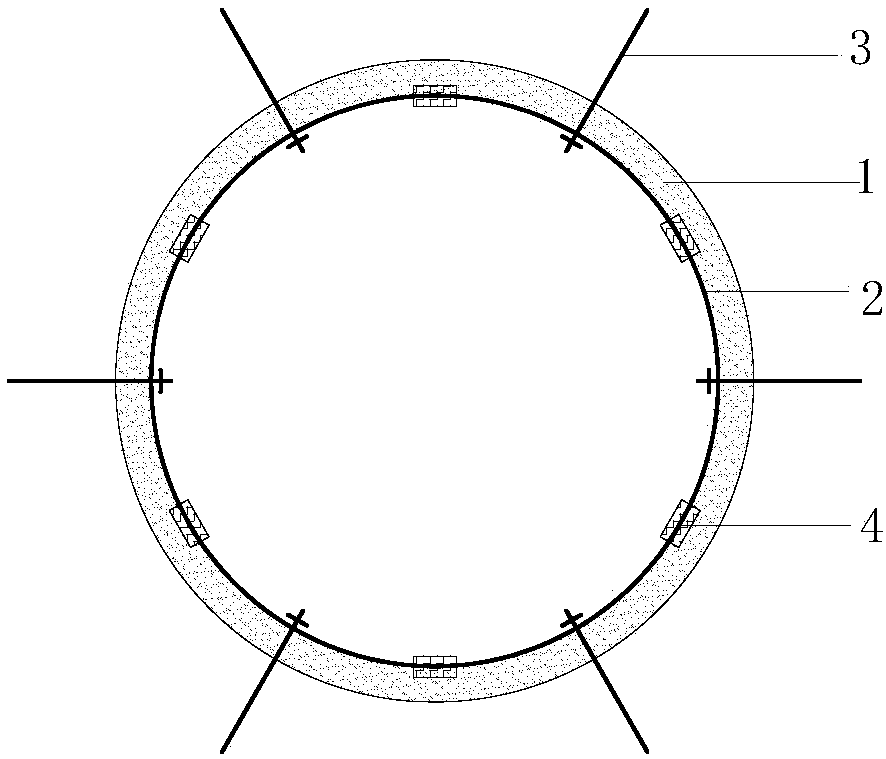

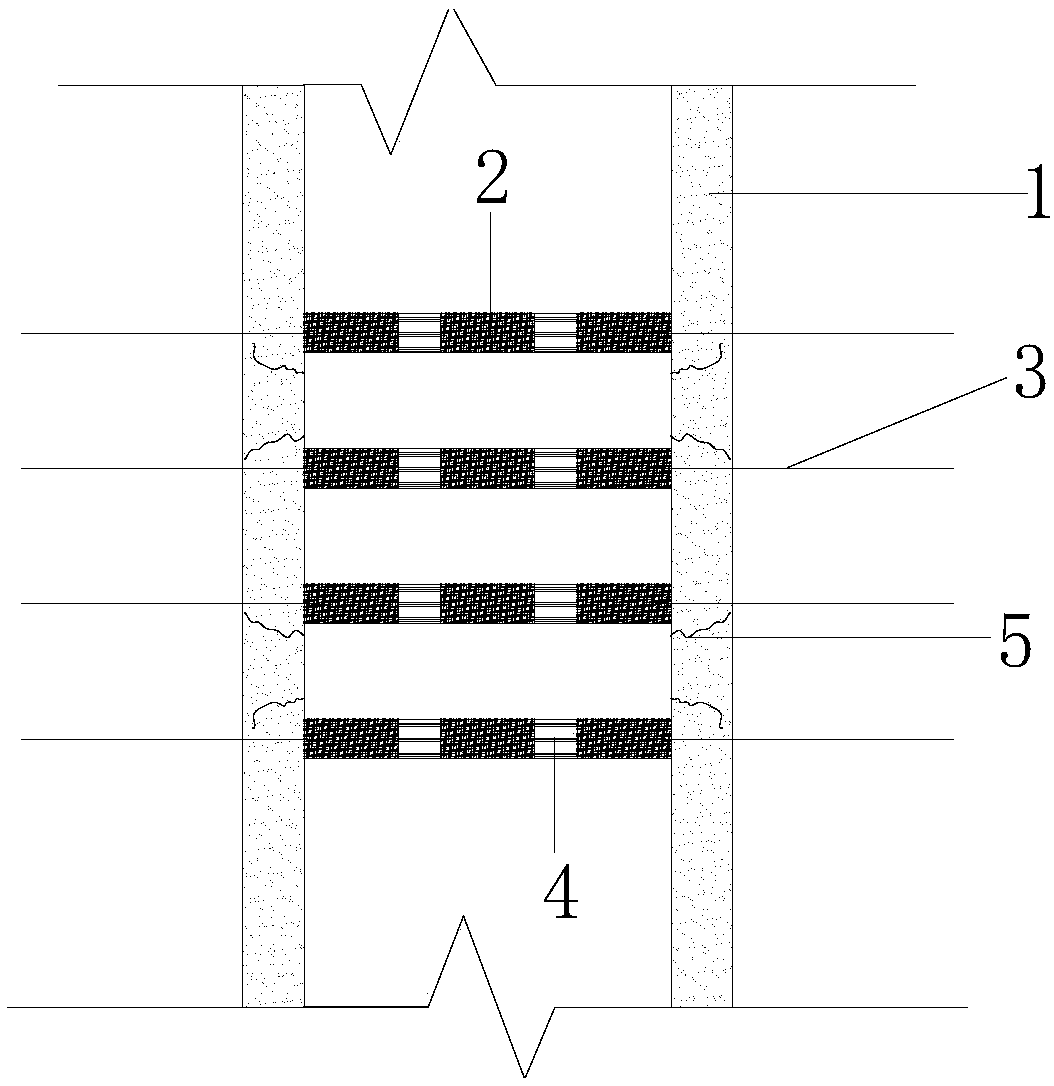

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0053] A different repair and reinforcement method based on the classification of the fracture degree of the borehole wall, including the following steps:

[0054] 1) According to the fracture range and depth of the wellbore wall, the fracture degree of the wellbore wall is divided into five categories from light to heavy: I-V:

[0055] Ⅰ. There are only cracks on the well wall, and the well wall is intact without falling blocks;

[0056] Ⅱ. The local damage depth of the well wall is within 500mm, and the damage area is not penetrated horizontally;

[0057] Ⅲ. The local damage depth of the well wall is greater than 500mm and less than 1000mm, and the damage area is not penetrated horizontally;

[0058] Ⅳ. The local damage depth of the well wall is greater than 1000mm, and the damage area is not penetrated horizontally;

[0059] Ⅴ. Horizontal penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com