Method for supporting triangular area in coal mine support-dismantling process

A technology for triangular area and coal mine, which is applied to the roof beam, mining equipment, earth-moving drilling, etc. to support the roof of the mine. , the effect of reducing physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

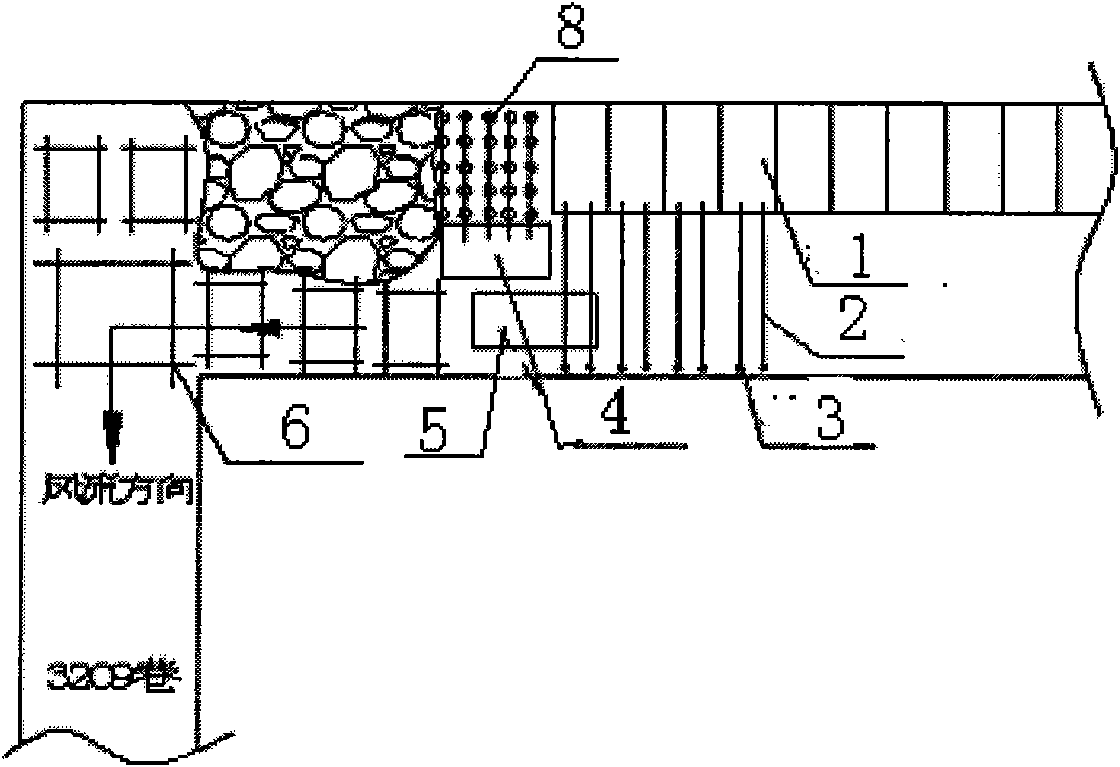

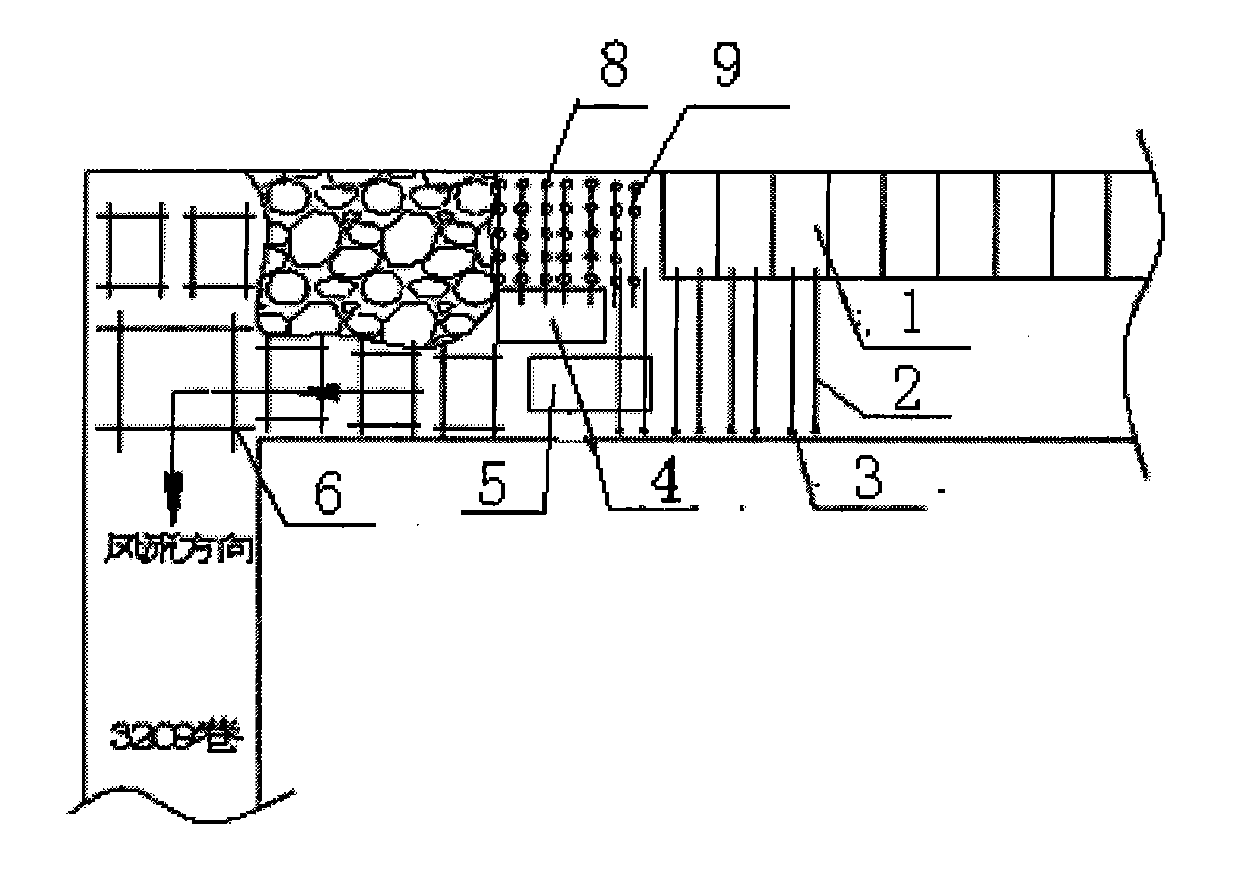

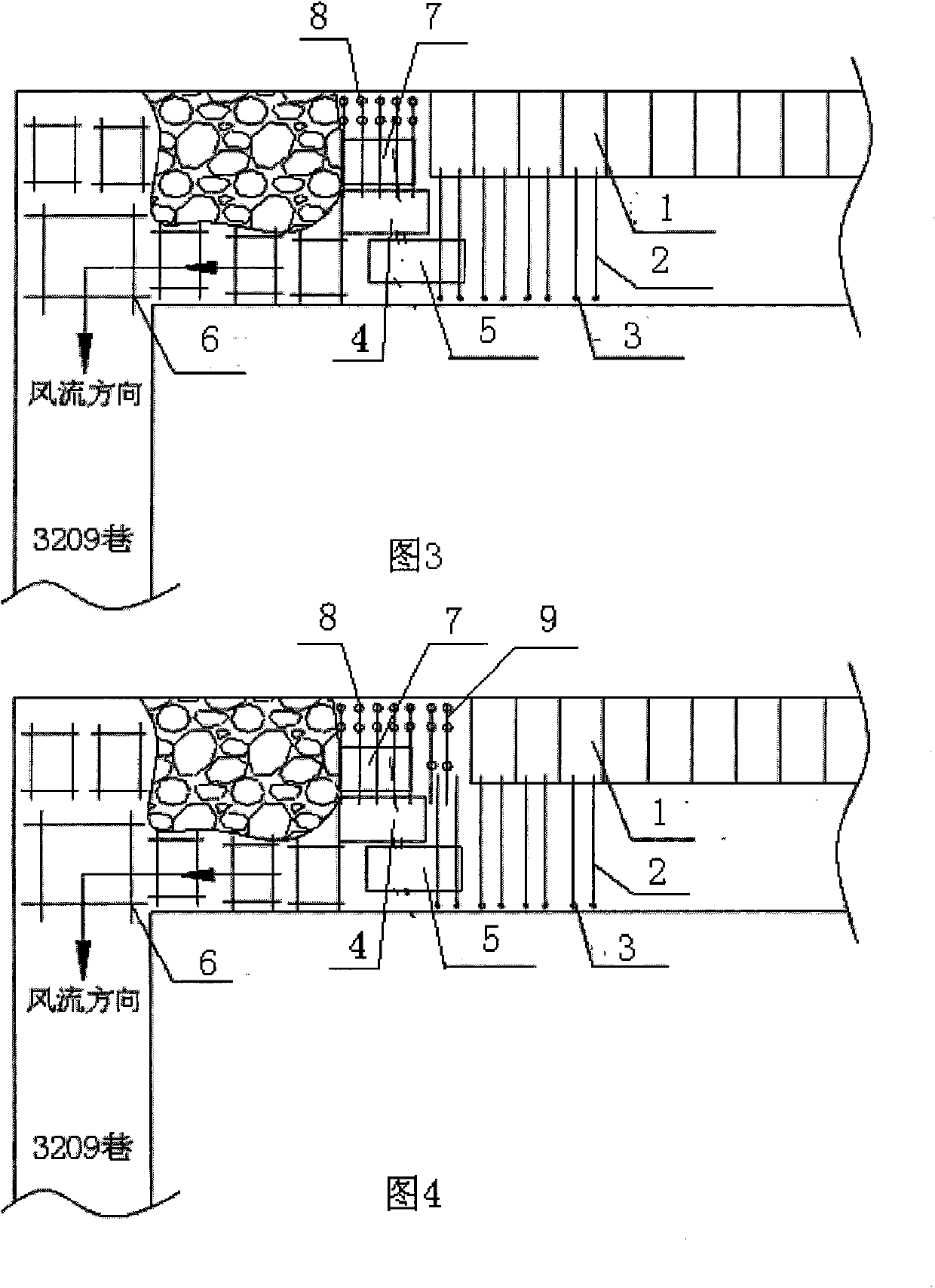

[0012] Such as image 3 , 4 As shown in the diagram, a support method for the triangular area of a coal mine is provided. Three protective frames 4, 5, and 7 are set in the triangular area. After each support 1 is withdrawn, two cantilevered sheds are erected at the original support position in the direction of the vertical protective frame. The 9 beams of the canopy are about 750±50mm away from the top beam of the next support to be removed, and the distance between the 9 beams of the two canopies is 750±50mm, which is supported by three columns (each canopy beam is cut from the side beam end of the old pond to the support to be removed) The top line is basically flush, supported by two single columns with a column distance of 400-800mm at the same time, and the other side is supported by a single column at a distance of 1-1.5m from the end of the beam, and at the same time, it must be ensured that this end can be covered in the middle The length on the front beam of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com