Comprehensive mining opposite-pull working face coal excavating process for thin coal bed

A technology for pulling working faces and coal mining faces, which is applied in ground mining, mining equipment, earthwork drilling and mining, etc. It can solve the problems of high tunneling rate of 10,000 tons in thin coal seams, low production efficiency and low benefit of comprehensive mechanized coal mining technology, etc. Waste of resources and other issues, to achieve the effect of saving excavation costs, effectively utilizing manpower, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A kind of fully mechanized thin coal seam coal mining technology, characterized in that: it includes:

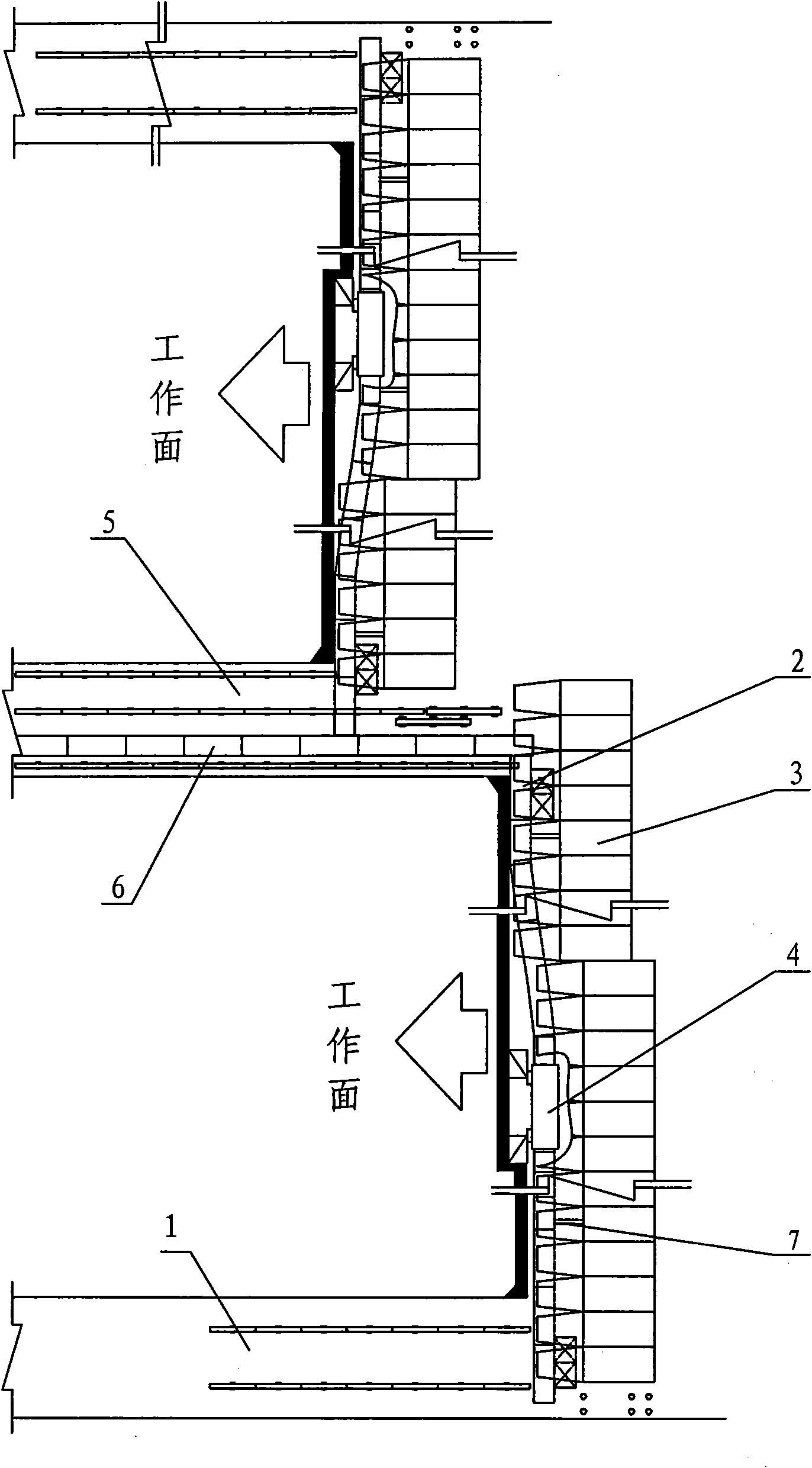

[0014] (1), there are two working face material lanes 1 and a central working face shared transportation lane 5 arranged side by side, the adjacent roadways are working faces, and the middle working face shared transportation lane 5 is selected as the shared roadway;

[0015] (2) Each working face is equipped with a working face shearer 4, a working face scraper conveyor 2, and a hydraulic support 3, and then the two working faces are side by side for comprehensive mechanized coal mining.

[0016] Since the two working faces share a transport roadway, the pressure on the top rock is relatively high. In order to ensure the support strength, the hydraulic support at the end of the working face and the "∏" steel greenhouse are jointly supported for the maintenance of the shared transport roadway. In order to leave the passage for personnel to enter and exit the common tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com