Coal face stump mining method

A mining face and mining method technology, applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of low coal recovery rate roadway excavation rate, low coal recovery rate, floor distortion and other problems, and improve coal recovery The effect of reducing the rate of excavation and reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

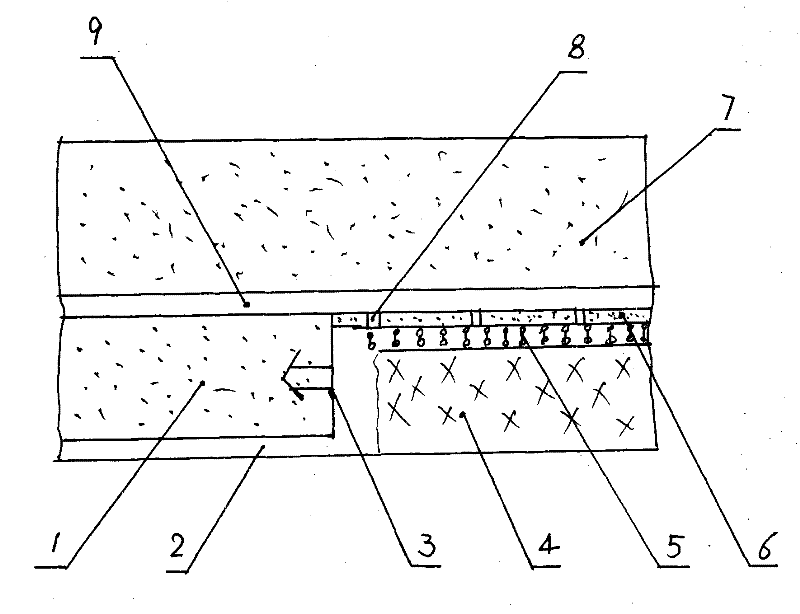

[0017] The specific implementation method of the gob-side entry retention of the present invention is described as follows with reference to the accompanying drawings:

[0018] first step:

[0019] Firstly arrange the coal mining face 3 of this section 1 according to the traditional way, promptly excavate the air return roadway 9, the transport level roadway 2 and the working face cut eye, and carry out mining according to the conventional method; it is characterized in that

[0020] Step 2: In the process of mining this section 1, a small coal pillar 6 with a width of 4 to 6 m is left along the goaf 4 on the side of the return air level roadway 9. When the coal is hard (f is greater than 3), take Small value, when the coal quality is soft (f is less than 3), take a large value, which is used to protect the return air entryway 9 in this section, so as to be used as the transportation entryway of the coal mining face in the next section 7;

[0021] Step 2: Drill a hole 8 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com