Gob-side entry retaining mining process for coal face

A technology of coal mining face and process method, which is applied in ground mining, mining equipment, earthwork drilling and other directions, can solve the problems of high cost of filling materials, failure of roadway retention, poor roadway protection effect, etc., and achieves elimination of roadway protection coal pillars Losses, reduce the 10,000-ton excavation rate, and improve the effect of resource recovery

Inactive Publication Date: 2015-06-17

鄂托克前旗长城煤矿有限责任公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 1. Masonry gangue belt technology: Poor pre-supporting ability may easily cause excessive sinking of the roof and break the roof of the roadway, which will eventually lead to the failure of the roadway retention

[0006] 2. Pillar or wooden pile support: many support materials are used, the workload is heavy, and the effect of support and roadway protection is poor

[0007] 3. Reinforce the metal bracket of the original roadway: the construction process is complicated, the safety is poor, and the roof is repeatedly supported, resulting in the roof breaking and breaking, and the roadway protection effect is poor

[0008] 4. Cement or other material filling process: complex process, large investment in equipment, high cost of filling materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

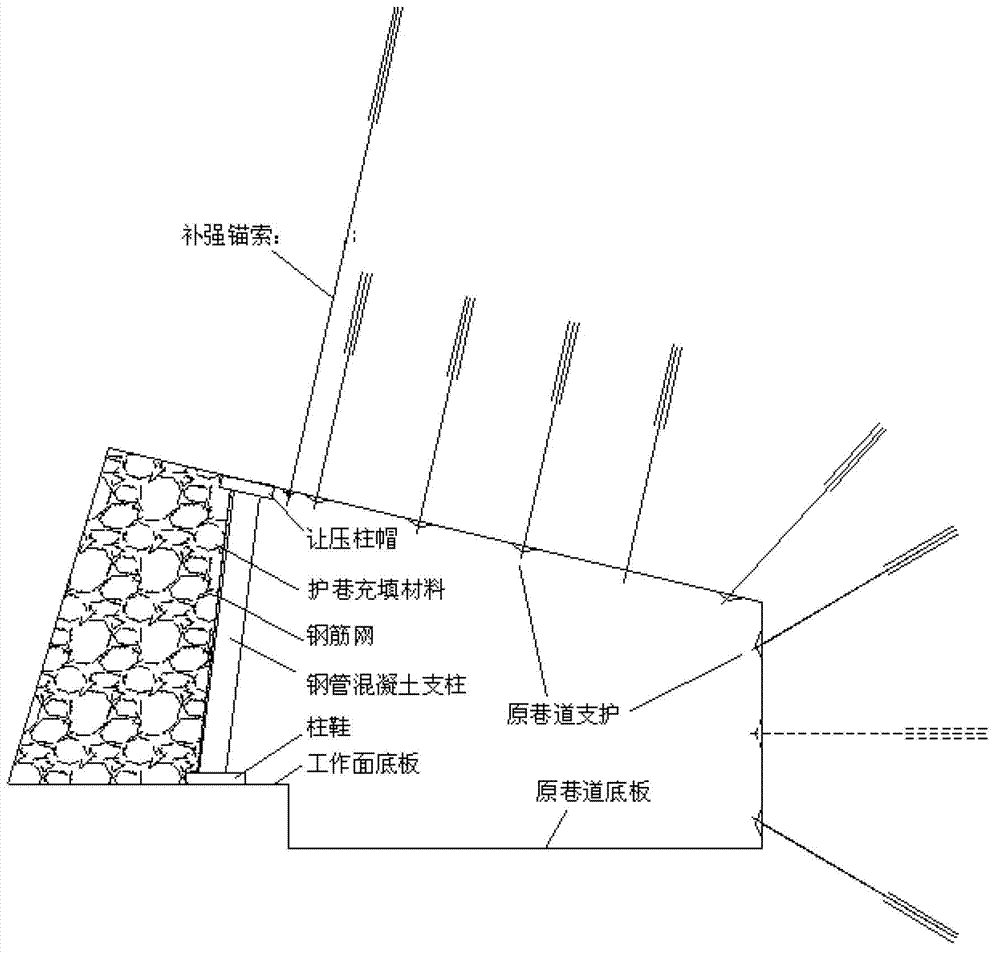

[0020] The specific implementation of the present invention is as described in the summary of the invention, those skilled in the art according to figure 1 and the record in the specification are fully practicable and will not be described in detail here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a gob-side entry retaining mining process for a coal face. The method comprises the following steps of: firstly performing temporary support on a top plate by supporting with two rows of hydraulic single support columns on the side of the designed entry retaining region beside the transport lane after the lower end of the coal face is pushed with one cycle during progress of the coal face; then performing normal support on the top plate by arranging a row of reinforcing anchor cables on the top plate of the original laneway in the position 0.3 meters from the support wall and arranging a row of steel pipe-concrete support columns on the top plate of the original laneway in the position 0.6 meters from the base plate of the original laneway; and finally performing support on a lateral wall shield lane by protecting the lane with reinforcement meshes in combination with woven bags loading gangue and then stacking gangue bags and finally injecting a concrete coating to cover the reinforcement meshes. The method fills in the blank of lane side-wall support and shield lane in the prior art, reduces the support cost, increases the support strength, greatly increases the construction speed, has a simple process and a significant effect, and effectively reduces the ten thousand ton-level drivage ratio.

Description

technical field [0001] The invention relates to the technical field of coal mining, and is suitable for medium and stable roof conditions, low gas mines, no rock burst and stress concentration zone structures, and fully mechanized mining working faces in near-horizontal and gently inclined thin coal seams and medium-thick coal seams. Background technique [0002] In order to reduce the loss of coal pillars during mining in fully mechanized coal mining faces, the gob-side entry retaining mining technique has been popularized on a large scale. [0003] At present, the mining technology of gob-side entry retaining mainly includes the following types: [0004] Masonry gangue belts, support dense pillars or wooden stacks, reinforce the metal brackets of the original roadway, and adopt molded or moldless filling technology. There are following deficiencies in the above several technologies. [0005] 1. Masonry gangue belt technology: Poor pre-supporting ability may easily cause ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21C41/16E21D19/00E21D11/00

Inventor 刘笃鸿陈东

Owner 鄂托克前旗长城煤矿有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com