A method of retaining half-alley and gob-side alley

A technology for empty roadway and roadway retention, which is applied in earthwork drilling, surface mining, underground mining and other directions, can solve the problems such as the inability to effectively solve the problem of the repair rate of the stope mining pressure roadway, and can solve the problem of gas over-limit in the upper corner and improve the Resource recovery rate and the effect of reducing the 10,000-ton excavation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

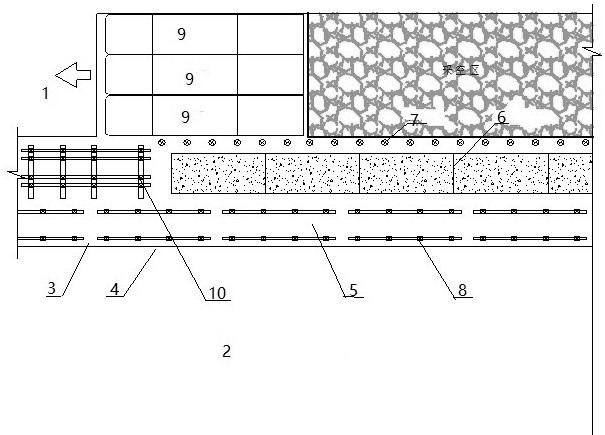

[0018] The maximum horizontal principal stress of the 15# coal seam 15108 coal mining face in a mine is 26.68MPa, the minimum horizontal principal stress is 14.36MPa, and the vertical stress is 18.79MPa, which is a medium-high stress area. , excavation along the roof and floor of the 15# coal seam, with a rectangular section, 4.2m wide, 4.0m high, and a sectional area of 16.8m2. The classification result of surrounding rock is grade Ⅳ, unstable surrounding rock. In the roadway, implement a method for retaining half-alley and gob-side entry of the present invention, the steps are:

[0019] In the return air trough 3 of the high-stress coal mining face 15108 (1), the gob-side retaining is carried out. The width of the entry retention is 1 / 2 of the width of the return air trough 3, which is 2.1m. In the return air trough 3 of the stress mining face 15108 (1), the height of the space 6 to be poured is the height of the return air trough 3, which is 4.0m, the width of the space ...

Embodiment approach 2

[0022] The burial depth of the 3201 coal mining face in the second mining area of the 3# coal seam of a mine is about 300m, the thickness of the coal seam is 7m, fully mechanized top coal caving mining, high gas mine, the return air channel is 4.2m wide and 3.5m high. In this roadway, a method of retaining a half-alley and gob-side entry of the present invention is implemented, and the gob-side entry is carried out in the return air trough of the high-stress coal mining face 3201. The width of the entry is 2.1m, and the space to be poured is arranged in In the return air channel of the high-stress coal mining face 3201, the height of the space to be poured is 3.5m, the width of the space to be poured is 1.0m, and the length of the space to be poured is 4.0m; after pouring, the roadway is reserved as the high-stress coal mining face 3201 The return air tunnel is used to form a Y-shaped one-inlet and two-return ventilation mode; when it is used as a replacement for the 3203 air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com