Down-dip mining method of shaped hydraulic bracket on long-wall working surface in direction of large dip angle coal bed

A technology of hydraulic supports and mining methods, which is applied in ground mining, pillars/supports, mining equipment, etc., can solve problems such as casualties and economic losses, aggravate the degree of sliding and dumping of hydraulic supports and related equipment, and safety production accidents. Guaranteed mining efficiency and construction progress, novel design, and the effect of reducing accident rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

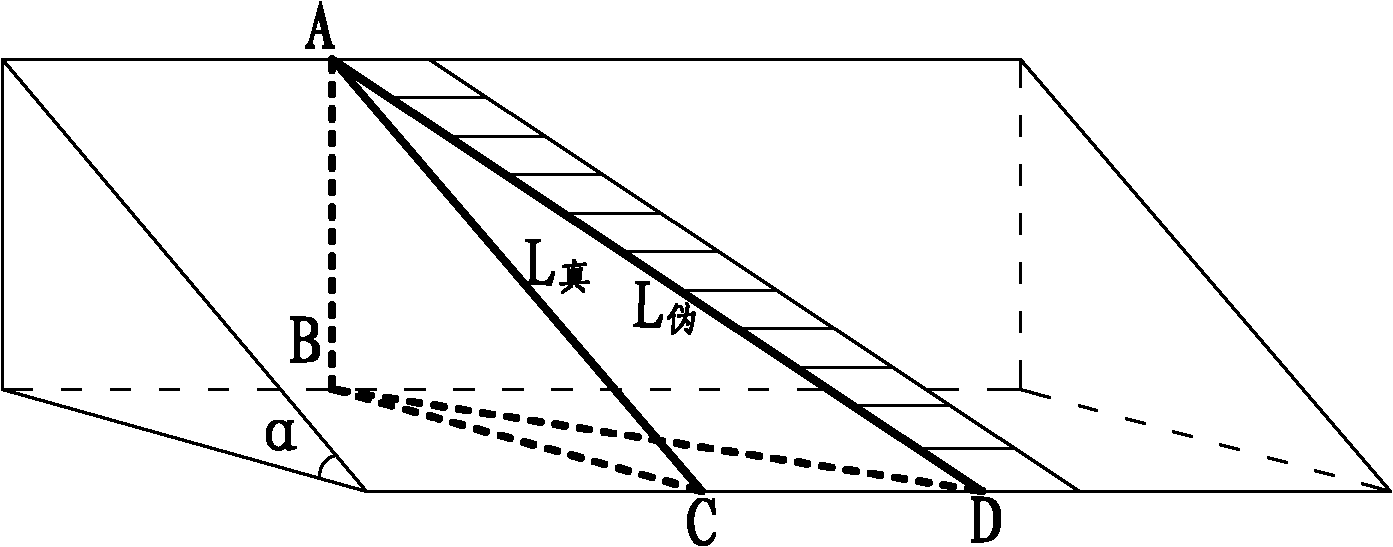

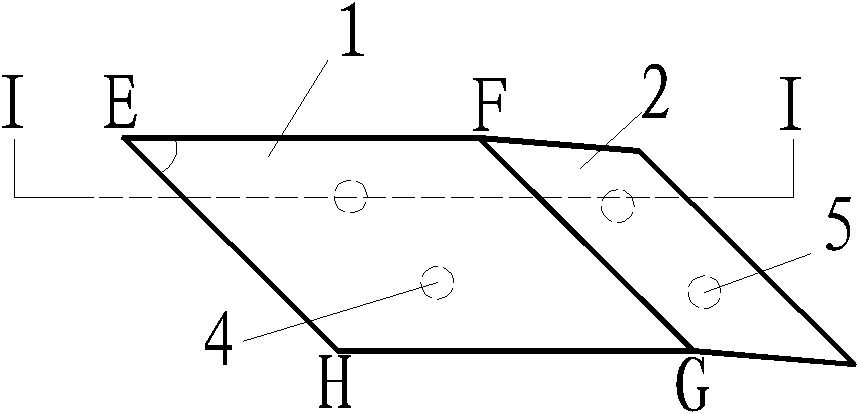

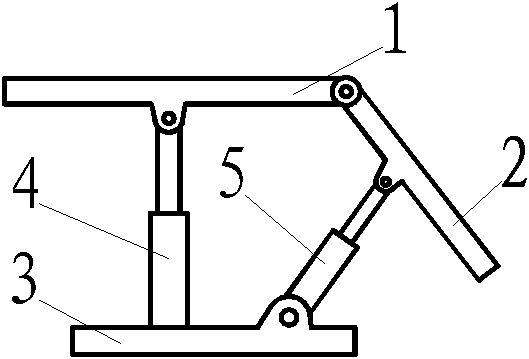

[0025] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, according to the present invention, a deep-dip mining method with a special-shaped hydraulic support for a long-wall working face with a large inclination angle coal seam is used. The large-dip angle coal seam is a coal seam with an inclination angle of 35° to 55°. The mining method includes the following steps:

[0026] Step 1. Determination of the pseudo-dip working face: select a pseudo-dip working face as the actual mining working face of the high-dip coal seam, and the included angle between the pseudo-dip working face and the horizontal plane is the pseudo-incline β 20°~35°, the included angle between the pseudo-dip working face and the seam strike of the high-dip coal seam, that is, the strike included angle is γ, the theoretical work of the pseudo-dip working face and the high-dip coal seam The angle between the faces is 90°-γ, the angle between the theoretical working face of the large-dip coal seam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com