Construction method of large-diameter coal bunker flat-topping lid

A construction method and large-diameter technology, which are used in earth-moving drilling, roof beams for supporting mine roofs, shaft linings, etc., can solve the problems of long construction period, high construction cost, low safety, etc., to ensure construction quality, Safe and reliable operation and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

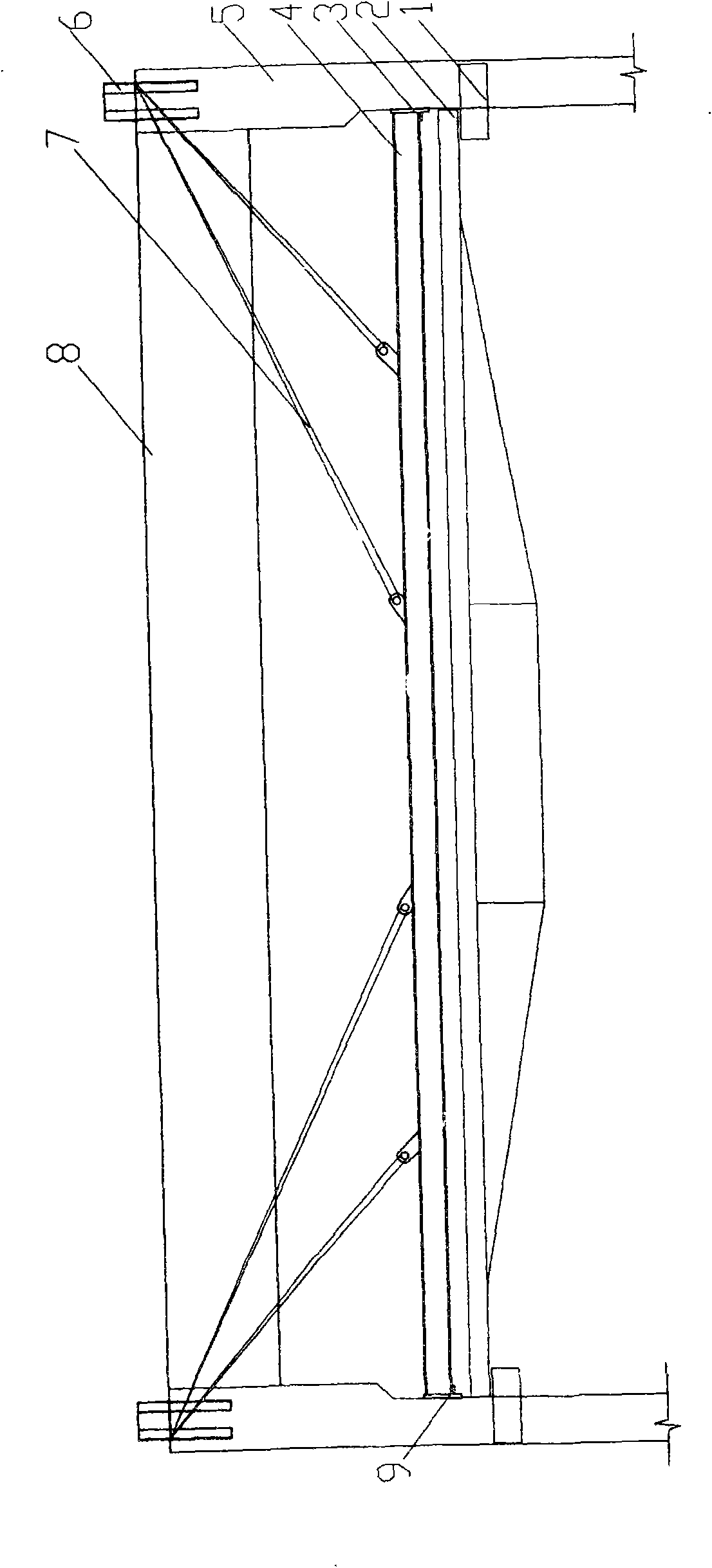

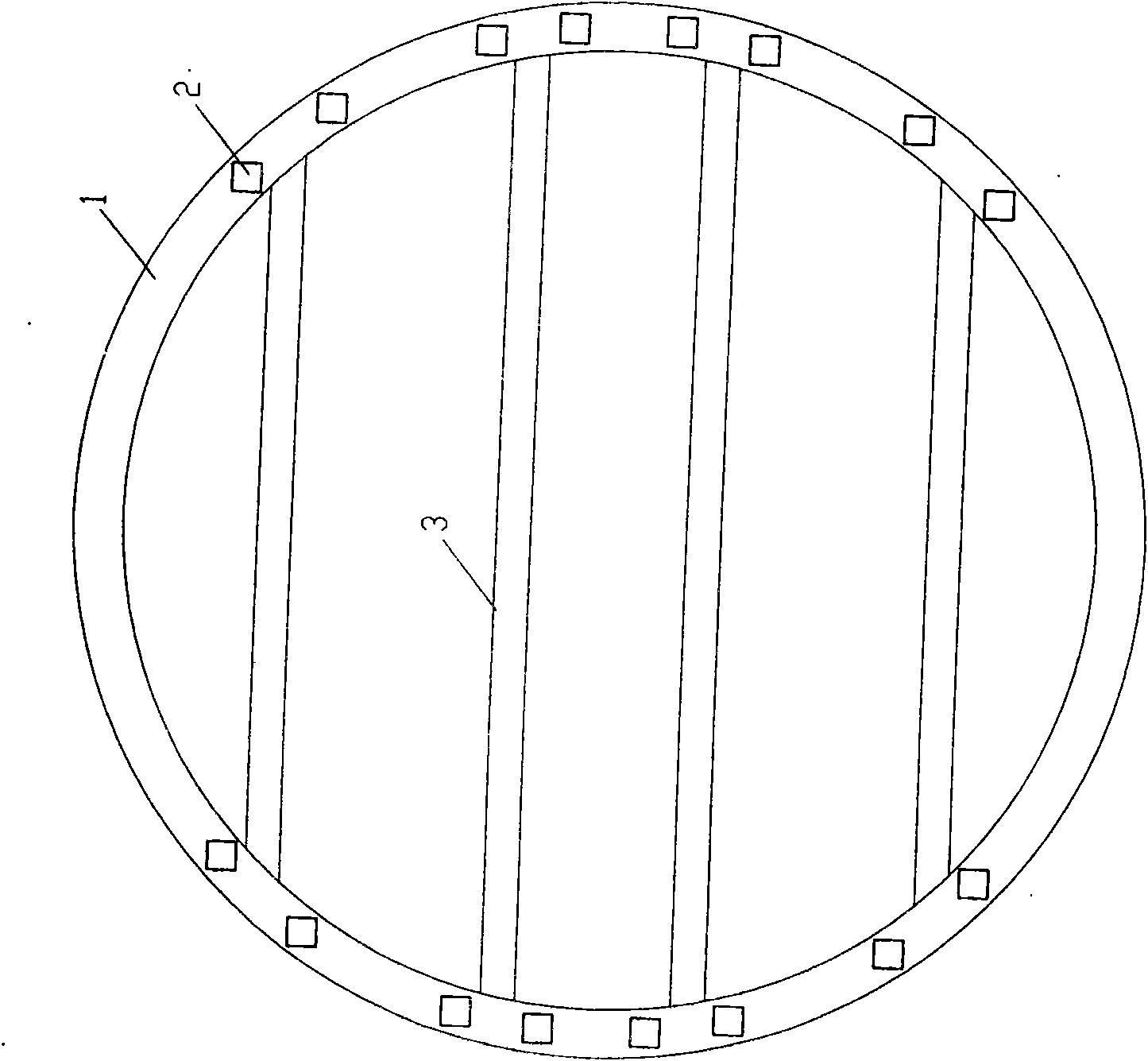

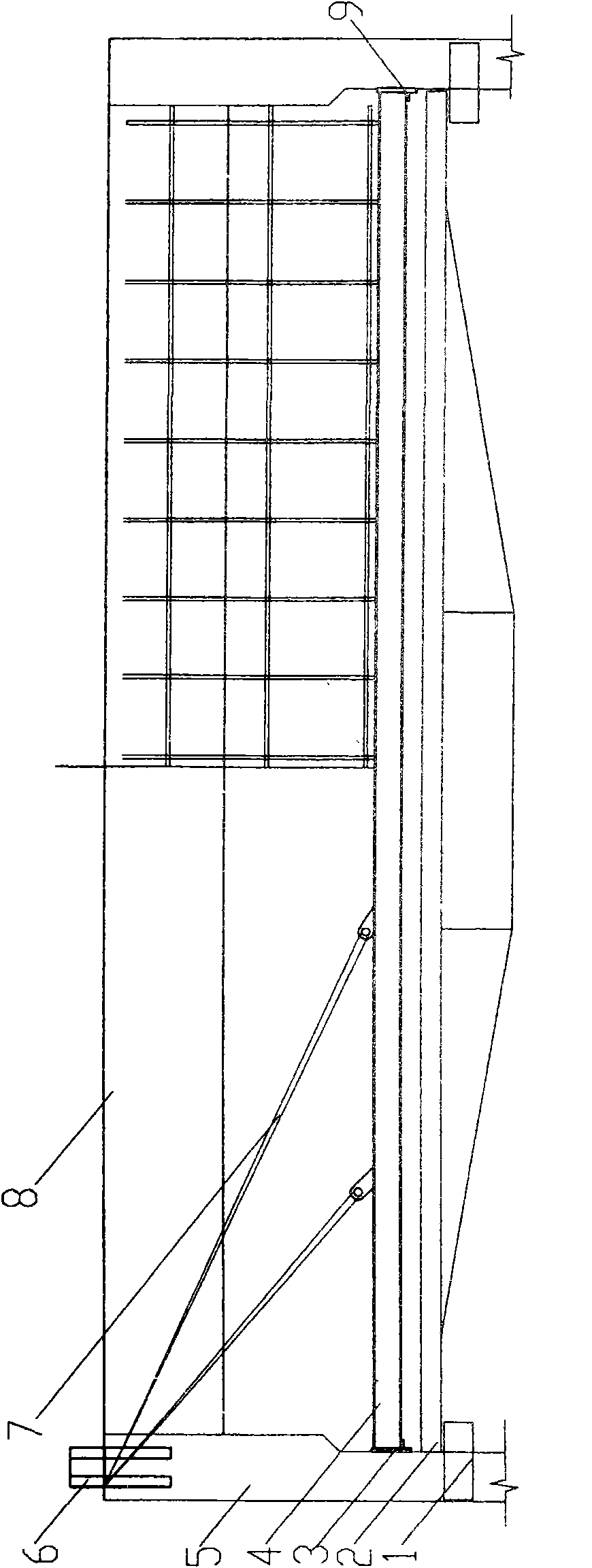

[0023] A construction method for a large-diameter coal bunker with a flat roof cover structure, the process steps of which are: ① determine the position of the H-shaped steel and the sliding form platform, ② pre-embed the steel plate in the inner wall of the coal bunker, and ③ pre-install the steel lattice column on the ring beam of the coal bunker wall. Buried, ④ sliding form platform lowered, ⑤ sliding form platform fixed, ⑥ welded and fixed H-shaped steel corbels, ⑦ H-shaped steel in place, ⑧ H-shaped steel reinforced, ⑨ roof main beam formwork installation, ⑩ main beam steel bar binding, Concreting of the main girder, Secondary beam and roof construction, Formwork and support system removed. The determination step of the position of the H-shaped steel and the sliding form platform is to specifically determine the positions of the H-shaped steel and the sliding form platform according to the design position of the main girder 8 of the coal bunker flat roof cover in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com