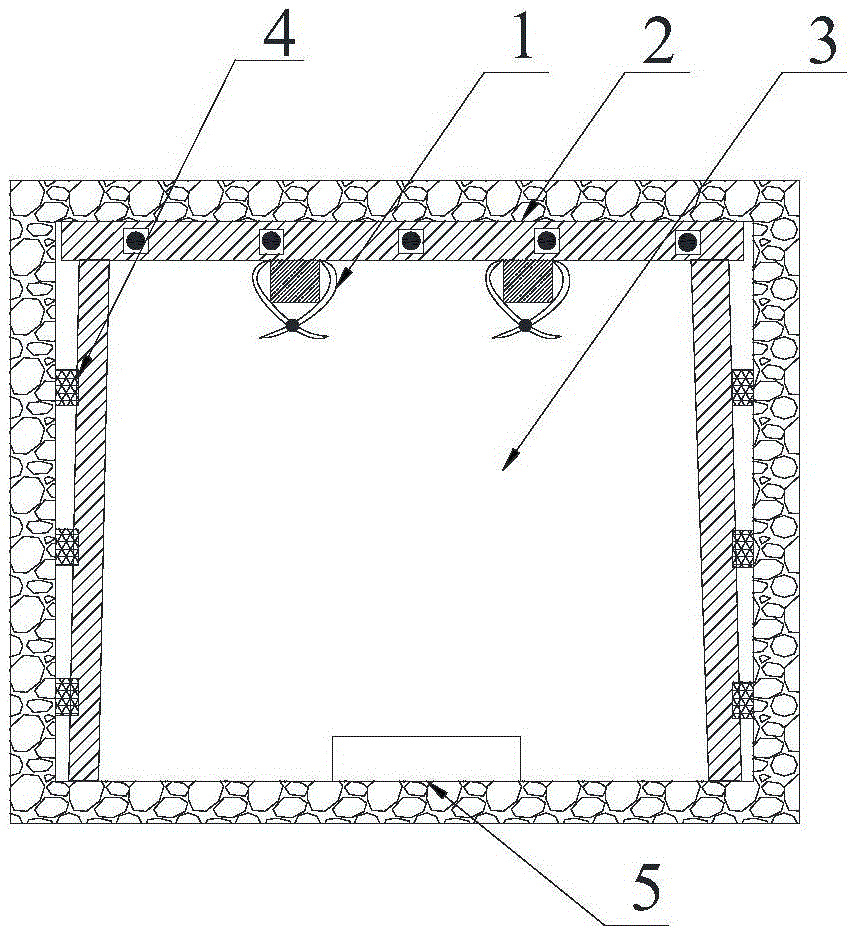

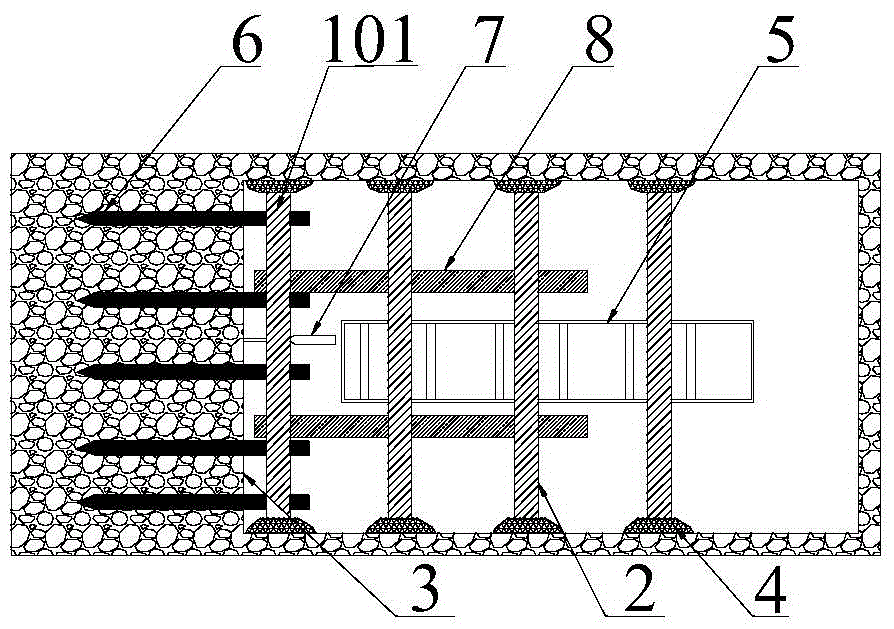

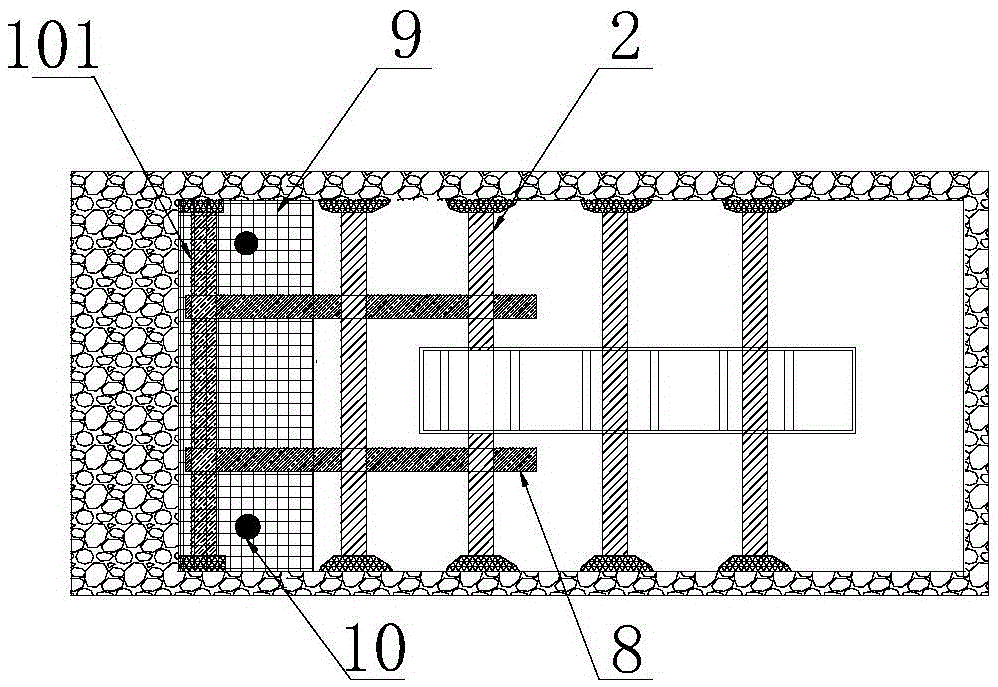

Method for tunneling coal bed repeated mining roadway in goaf

A technology for gobs and roadways, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of affecting the economic benefits of re-mining, affecting the speed of excavation, and the difficulty of support, so as to shorten the time of excavation and improve coal recovery High efficiency, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The basic situation of Taiping Coal Mine re-mining area is as follows:

[0082] From November 1998 to November 2000, a total of 792,000 tons of raw coal were mined at the 6301 working face;

[0083] From October 2001 to September 2002, a total of 882,000 tons of raw coal were mined at the 6303 working face;

[0084] From March 2000 to May 2002, a total of 675,000 tons of raw coal were mined at the 6305 working face;

[0085] From February 2001 to September 2001, a total of 469,000 tons of raw coal were mined at the 6307 working face.

[0086] By calculation, the remaining recoverable reserves in the re-production area are about 1.071 million tons.

[0087] The lower tunnel roadway of 303 in the re-mining area is within the scope of the original 6305 working face. The thickness of the remaining coal seam discarded in the goaf after mining in the 6305 working face is 0-5m, with an average of 3m. It is a stable coal seam with a simple structure and a hardness coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com