Heavy large-mining-height full-protection large-dip-angle long-wall fully mechanized caving face automatic control supporting equipment

A fully-mechanized caving face and large mining height technology, which is applied to mining equipment, earthwork drilling, mine roof support, etc., can solve the problems that it is difficult to apply to the long-wall fully mechanized caving face with large inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] The preferred specific implementation of the heavy-duty, large mining height, fully protected and large dip angle longwall fully mechanized caving face automatic control support equipment of the present invention is as follows:

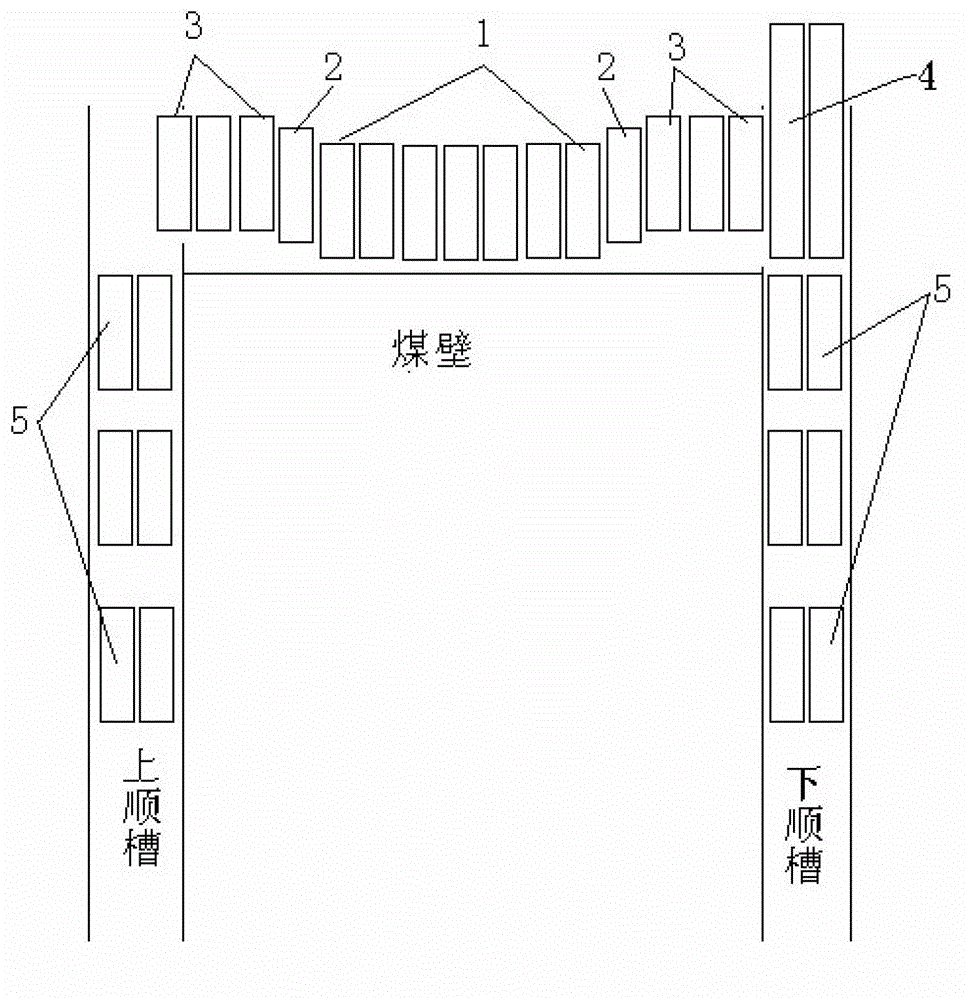

[0036] Including multiple brackets, there are multiple intermediate brackets on the working surface, 1 to 2 transition brackets and 2 to 4 head brackets are respectively arranged on both sides of the middle bracket, and 2 Up to 4 sets of advanced brackets, each group of advanced brackets includes two advanced brackets arranged side by side, and a set of end brackets is arranged at the position where the horizontal groove is aligned with the leading bracket and the longitudinal direction is aligned with the advanced bracket;

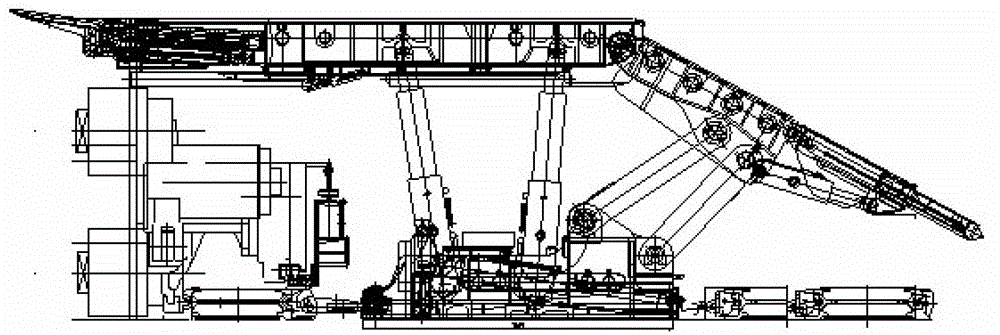

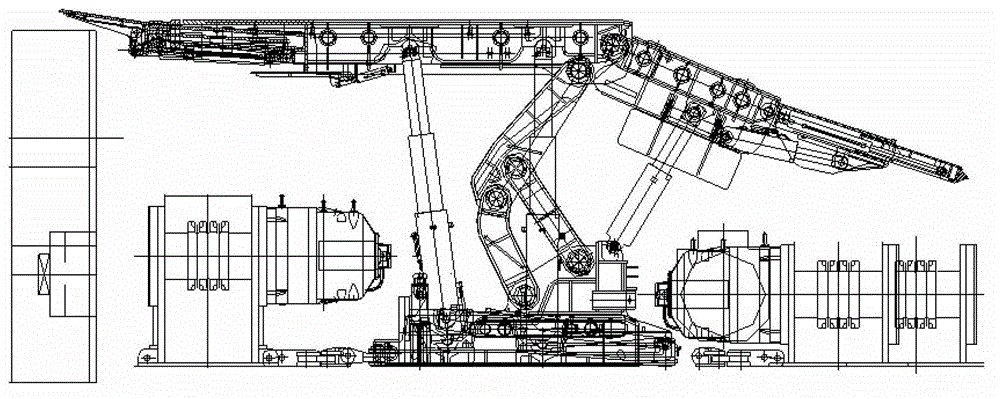

[0037] Described one group of end brackets comprises two end brackets arranged side by side, wherein the end brackets away from the working surface are provided with four rear columns, four middle columns, and two front col...

specific Embodiment

[0047] 1. Supporting equipment on the working surface, such as figure 1 shown, including:

[0048] Shearer: MG450 / 1020-WD;

[0049] Front and rear scraper machine: SGZ960 / 1400 scraper conveyor;

[0050] Reprinter: SZZ1000 / 400;

[0051] Crusher: PLM3000;

[0052] Belt conveyor self-moving tail: DY1200;

[0053] Reprinter self-moving device: MY800;

[0054] Intermediate support: ZF8600 / 18 / 35D caving hydraulic support (extended product ZF10000 / 18 / 35D);

[0055] Transition support: ZFG8600 / 18 / 35D transition hydraulic support (extended product ZFG10000 / 18 / 35D);

[0056] Header support: ZFP8800 / 20 / 36D head hydraulic support (extended product ZFG11000 / 18 / 35D);

[0057] End bracket: ZT20000 / 21 / 38 (1 set of 2 racks);

[0058] Advance support with upper and lower troughs: ZT8670 / 23 / 35 roadway support.

[0059] 2. Equipment application location:

[0060] Shenhua Ningxia Coal Group Zaoquan Coal Mine (extended product Shenhua Ningxia Coal Group Yangchangwan Coal Mine);

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com