Method for weakening coal-rock mass by hydraulic blasting and fracturing

A hydraulic blasting and hydraulic fracturing technology, which is applied in the direction of mining fluid, earthwork drilling, and discharge machinery, etc., can solve problems such as difficult to control the expansion of cracks in holes, weakening the effect of top coal or roof, and easy to cause danger due to poor control , to achieve wide practicability, convenient construction, and the effect of preventing rock burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

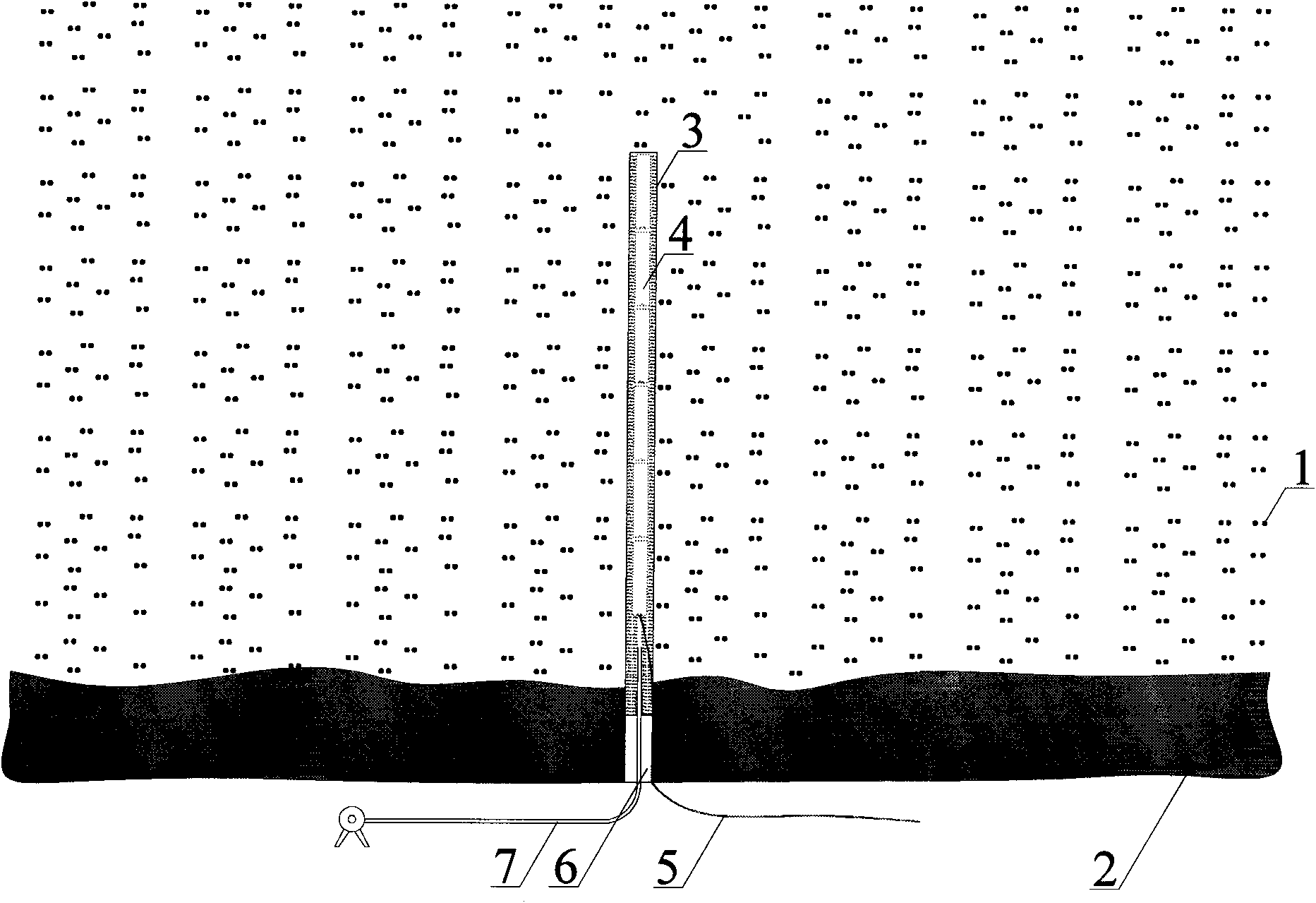

[0013] Embodiment one: the average thickness of a certain mine coal seam is 4m, and the hardness of coal seam 2 is f=3, is nearly horizontal coal seam 2, and the overlying strata is hard sandstone 1, and its average thickness 25m, coal seam of coal mining working face under the coal mine In 2, a drilling rig is used to drill a hydraulic fracturing weakening drill hole 3 toward the roof, the depth of the drill hole 3 is 20m, and the hole diameter is 60mm. The spacing of the holes is about 15m, and the water gel explosive 4 is put into the holes, and the charge is 40g. Lead the lead wire 5 to the outside of the borehole, then use the hole sealer 6 or cement mortar to seal the borehole opening, and then inject high-pressure water into the borehole through the high-pressure water injection pipe 7 to ensure that no hydraulic cracks occur. Stop water injection, detonate water glue 4 explosives and carry out hydraulic blasting. Under the action of blasting pressure, the surrounding r...

Embodiment 2

[0014] Embodiment two: the average thickness of a certain coal mine seam is 9m, the hardness of coal seam 2 is f=4, is a nearly horizontal coal seam, and the mining ratio is 1: 2, and in the coal seam 2 of the coal mining face in the coal mine, a drilling rig is used to move toward Drill holes 3 on the roof, the depth of the holes 3 is 50m, the diameter of the holes is 60mm, and the distance between the holes is 15m. Put water gel explosive 4 in the hole, the charge is 60g, lead the lead wire 5 out of the drill hole, then use the hole sealer 6 or cement mortar to seal the drill hole, and then pass the high-pressure water injection pipe 7 to Inject high-pressure water into the borehole, subject to no hydraulic cracks, stop the water injection, detonate the water gel explosive 4 to carry out hydraulic blasting, under the action of the explosion pressure, the surrounding rock of the borehole will be broken, and a large amount of water will be generated around the borehole. Cracks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com