Caving cleaning device

A technology of cleaning device and caving, applied in construction and other directions, can solve the problems of no backfilling, untimely backfilling of cavities, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

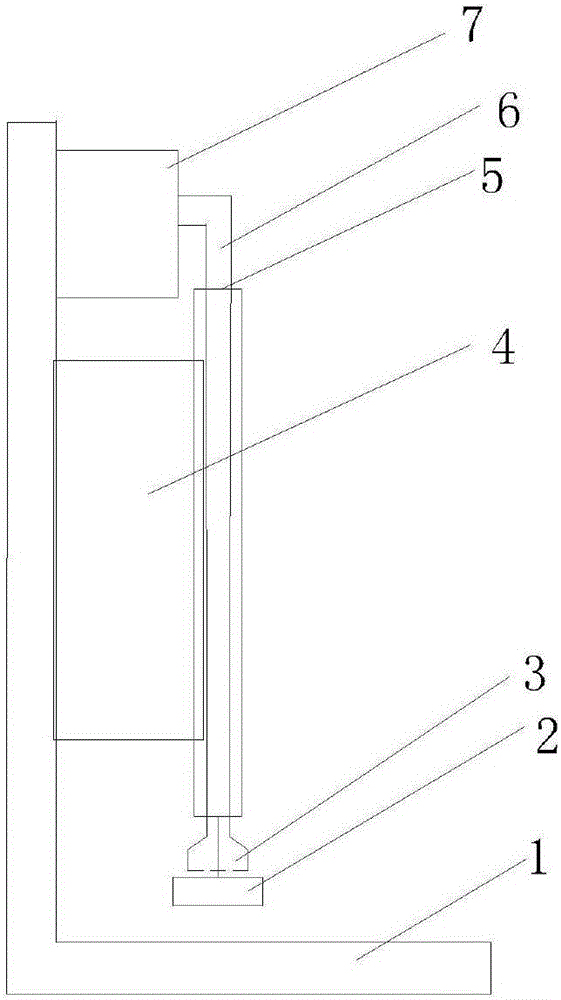

[0017] Such as figure 1 Shown is a structural representation of an embodiment of a cave cleaning device of the present invention figure 1 ; Including bracket 1, lifting mechanism-4, drill pipe 5, recovery device; said lifting mechanism-4 is installed in cooperation with support 1; said drilling rod 5 is installed in cooperation with lifting mechanism-4; said recovery device is matched with lifting mechanism-1 4 Cooperate installation; the recovery device includes an air duct 6 and an air extraction device 7; the air extraction device 7 is connected to the air duct 6; the air inlet 3 of the air duct 6 is located at the rear of the drill bit 2 and moves up and down with the drill bit 2.

[0018] During application, the drill rod 5 is aligned with the exploration hole, and enters the detection hole while rotating; while the drill rod 5 rotates, or when the drill rod 5 is inside the exploration hole, the air extraction device 7 starts to work; the broken bits cut off by the drill ...

Embodiment example 2

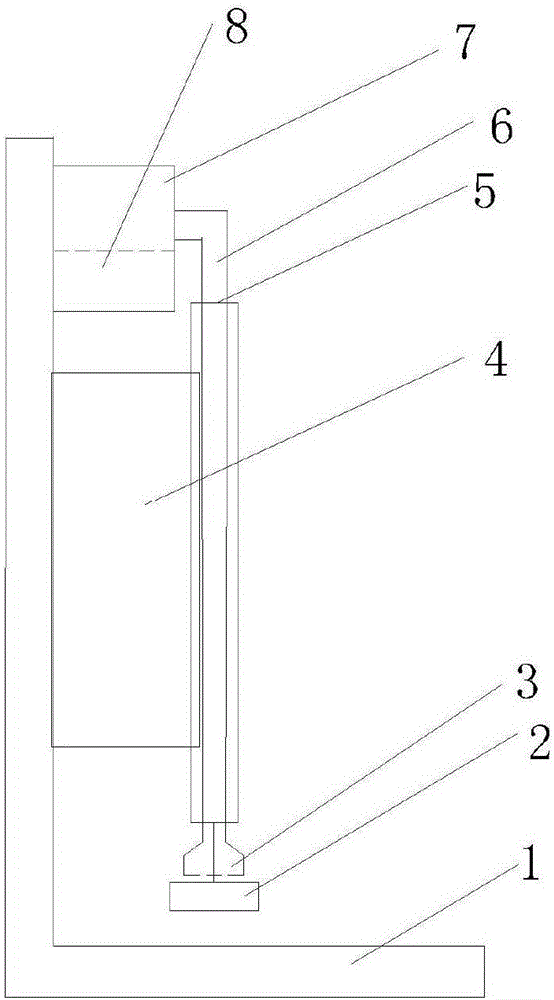

[0025] Such as figure 2 Shown is a structural representation of an embodiment of a cave cleaning device of the present invention figure 2 .

[0026] The difference between the second implementation example and the first implementation example is that a dust recovery device 8 is added; the dust recovery device 8 is mated with the air duct 6 . The dust recovery device 8 is installed in cooperation with the bracket.

[0027] The dust recovery device 8 includes at least one of the bag dust removal device, centrifugal dust removal device, wet dust removal device, and electrostatic dust removal device in the prior art; preferably, it is a combination of the bag dust removal device and the wet dust removal device.

[0028] The air inlet of the bag dust removal device is connected to the air outlet of the air duct 6; the air outlet of the bag dust removal device is connected to the air inlet of the wet dust removal device.

[0029] The invention provides a mechanized caving clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com