Filling mining method for caving zone on coal face

A technology of coal mining face and mining method, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of large ground space restrictions, large space and time restrictions, and low coal mining efficiency in the working face, and achieve the goal of overcoming the production capacity. Effect of low, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

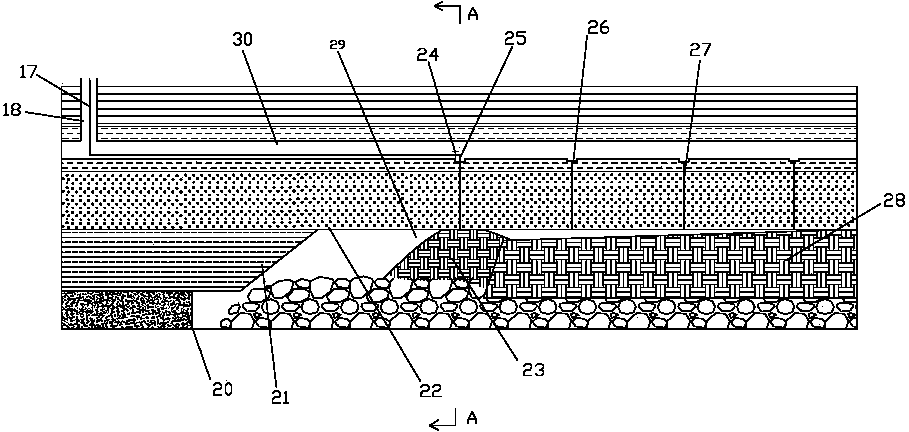

[0023] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

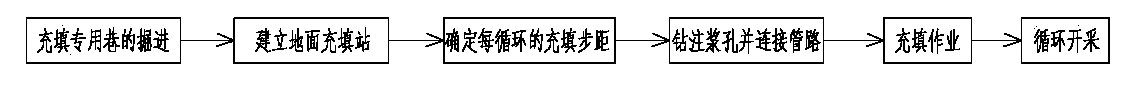

[0024] by Figure 1 to Figure 4 Given, the present invention is realized by the following steps:

[0025] (1) Excavation of special filling lanes

[0026] According to the condition of the overlying strata on the coal mining face, combined with the key layer theory of rock strata control, the position of the stable rock strata above the overlying strata of the working face and the nearest to the working face is determined. According to the magnitude of the in-situ stress, the mechanical properties of the rock strata, and the difficulty of special road support To determine the construction location and section size of the special filling lane 30, the conventional method is used to complete the excavation and support of the special filling lane;

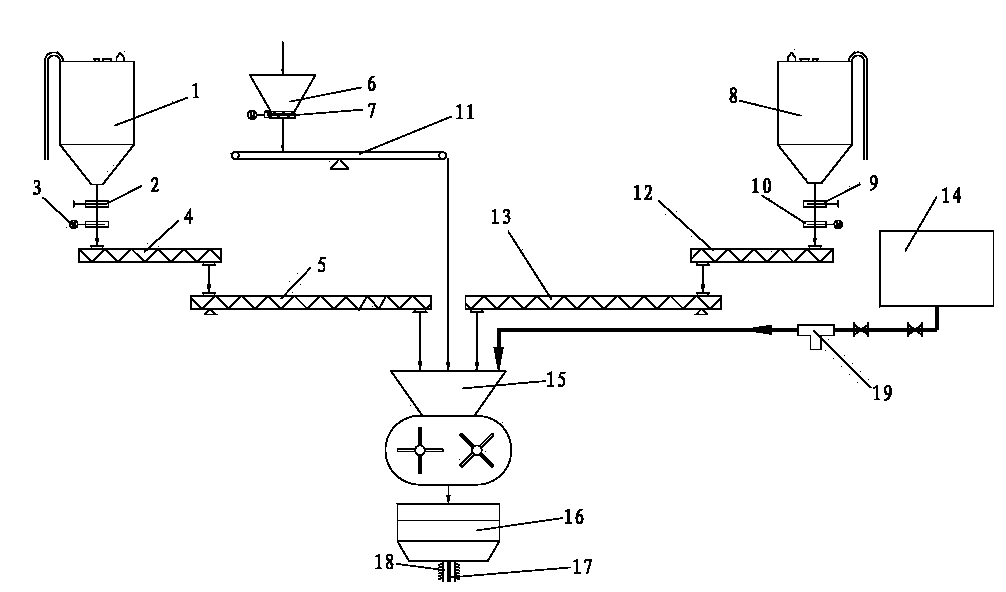

[0027] (2) Establish ground filling station

[0028] While filling the special lane construction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com